Continuous cutting and automatic discharging cutting machine special for angle valve quick opening

A technology of automatic cutting and cutting machine, which is applied to the device for shearing and forming blanks, the shearing device, the attachment device of the shearing machine, etc., can solve the problems of complex realization, high risk, high labor intensity, etc. Efficiency, avoiding cutting errors, reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

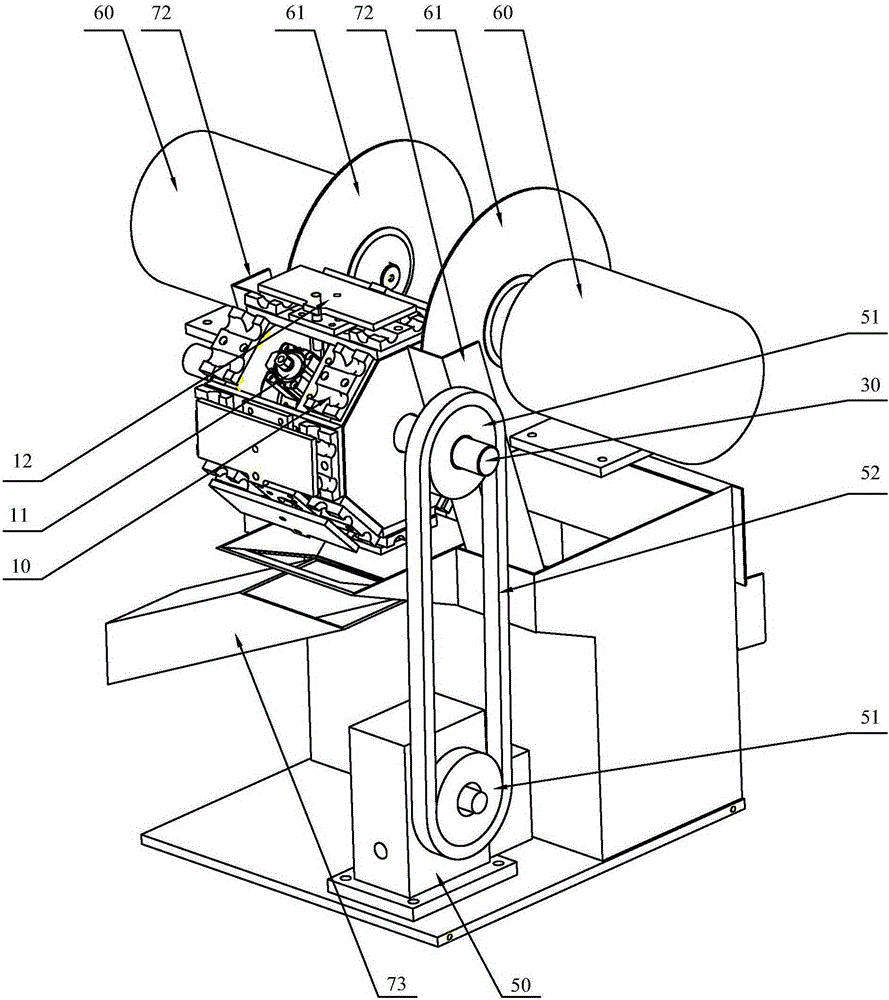

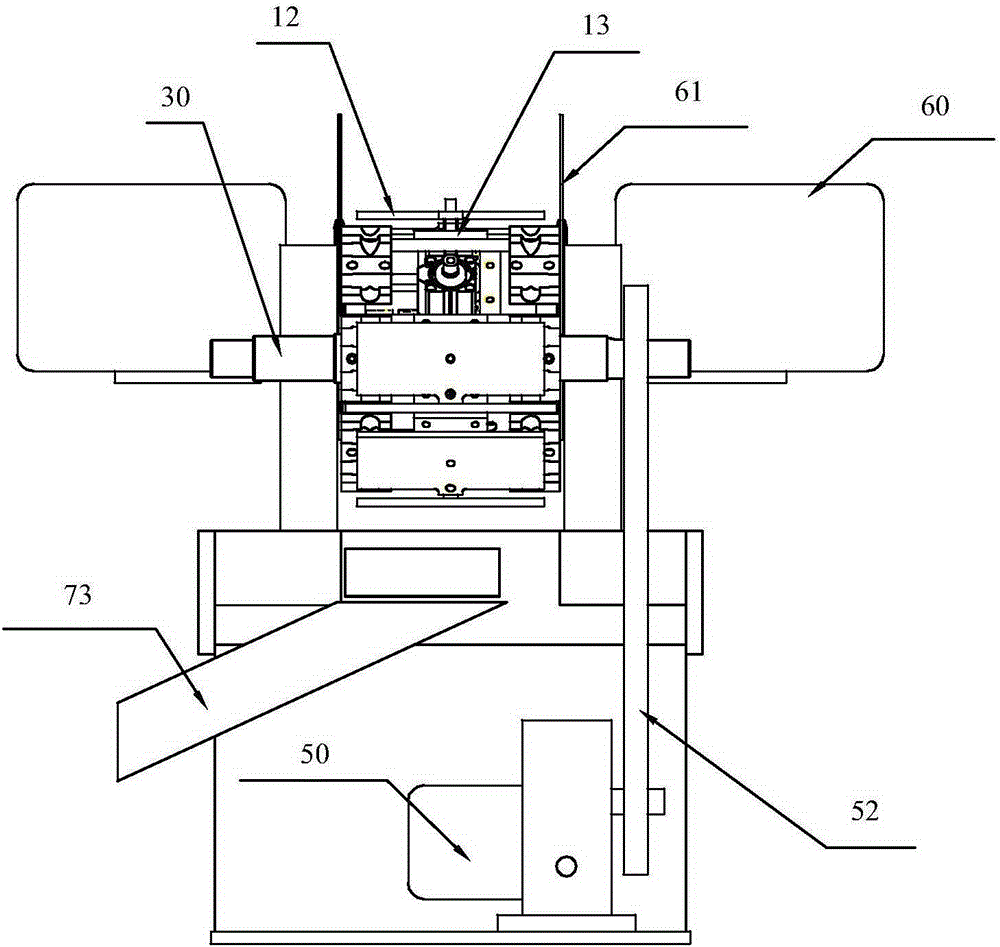

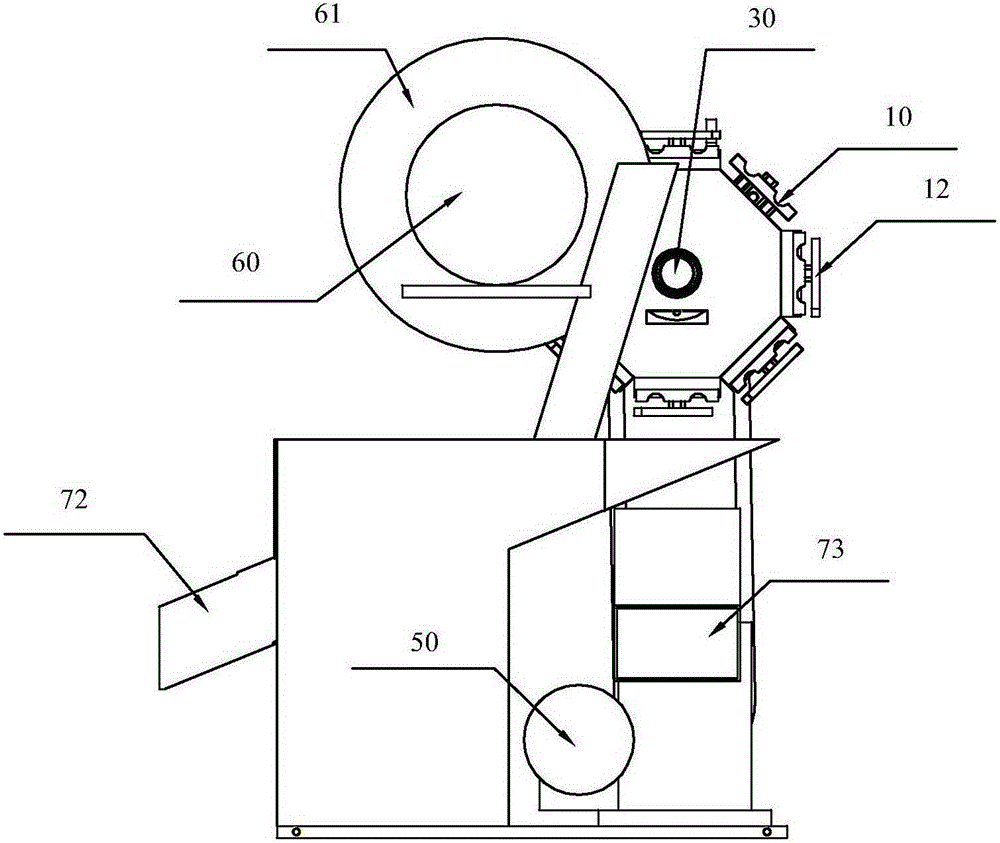

[0036] In order to overcome the deficiencies of the cutting machines in the prior art, the present invention provides a special cutting machine for quick opening of angle valves with continuous cutting and automatic blanking, such as Figure 1 to Figure 4 As shown, it includes a rolling feeding mechanism and a cutting mechanism, and the blank sample is fixed on the jig of the rolling feeding mechanism. The cutting mechanism includes a cutting piece 61 and a cutting motor 60, and the cutting piece 61 of the cutting mechanism is aligned with the cutting point of the blank sample to set; the rolling feeding mechanism carries out rolling feeding around the horizontally arranged rotating shaft 30; The blank sample is fixed, the rolling feeding mechanism drives the blank sample to roll to the cutting piece 61, the cutting mechanism cuts the blank sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com