a fuel catalyst

A fuel catalytic core and catalytic converter technology, applied in chemical instruments and methods, fuel re-atomization/homogenization, chemical elements of heterogeneous catalysts, etc. and other problems, to achieve the effect of increasing the calorific value of combustion, reducing engine wear and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

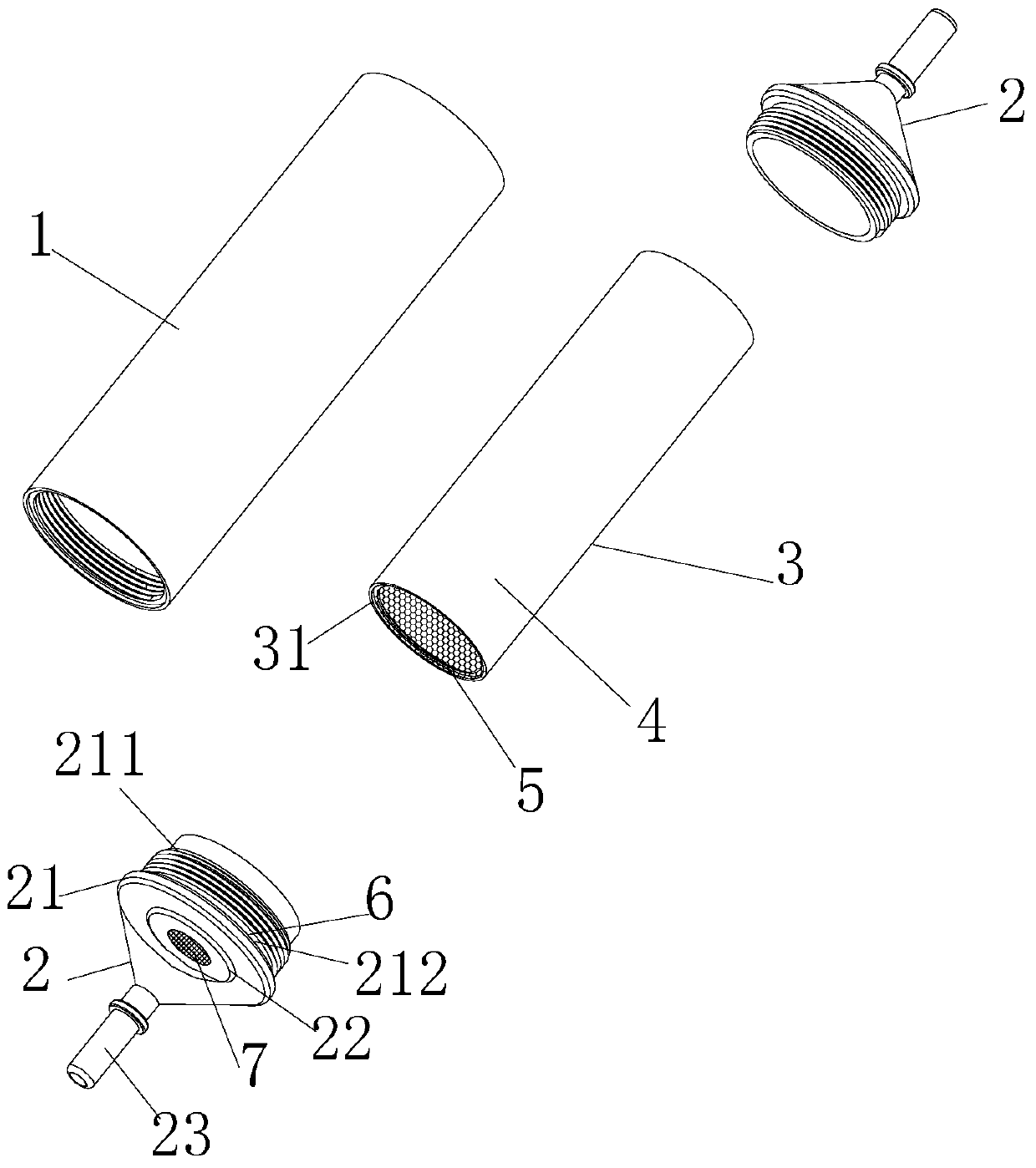

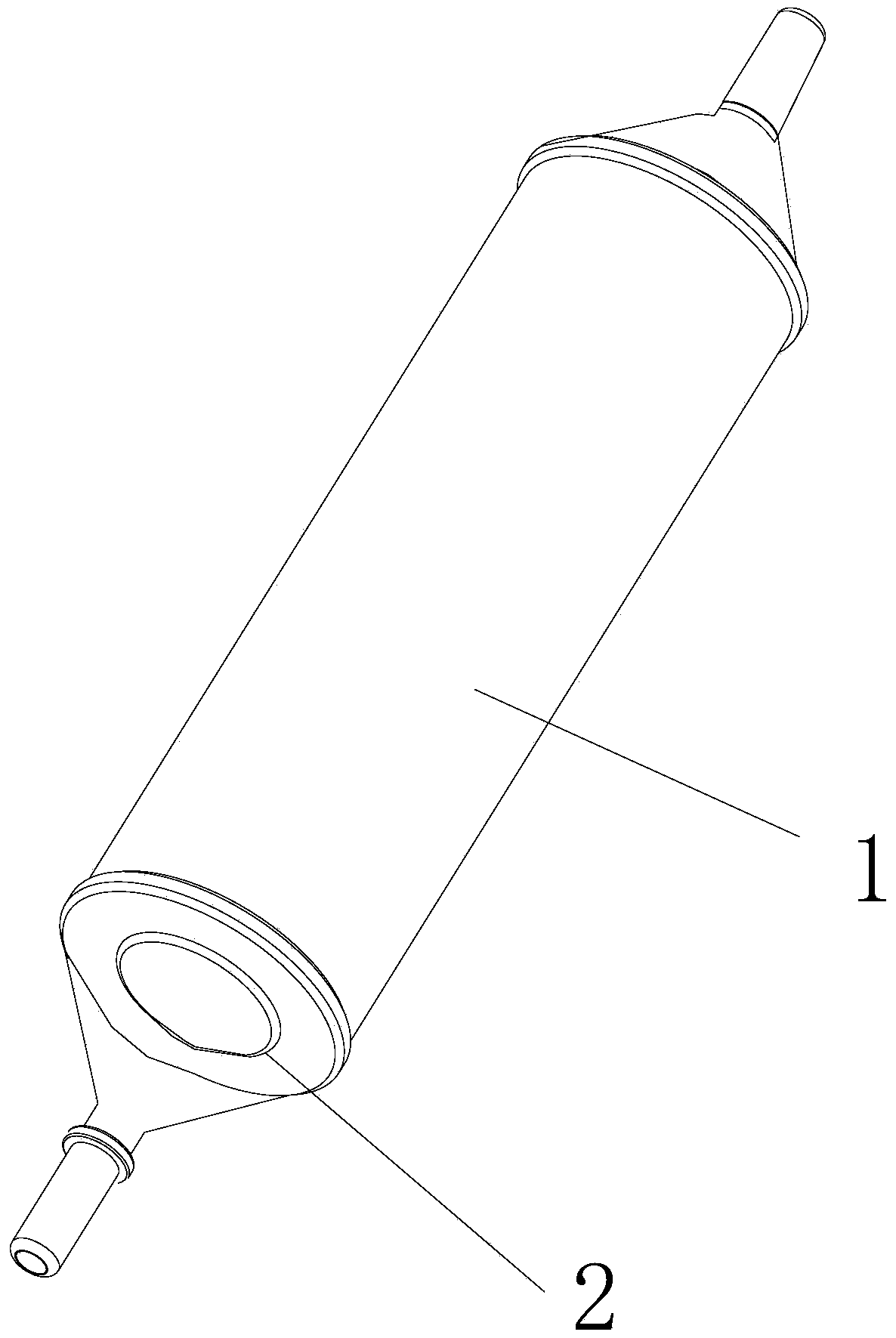

[0041] as attached Figure 1-3 As shown, a fuel catalytic converter includes a structural main body 1, the structural main body 1 is a hollow columnar structure, the two ends of the structural main body 1 are respectively provided with a cover 2, and the cover 2 is provided with an oil pipe connection Port 23, the structural main body 1 is provided with a hollow carrier shell 3, the carrier shell 3 is filled with a fuel catalyst core 4, the fuel catalyst core 4 includes a honeycomb catalyst carrier 5, and the surface of the honeycomb catalyst carrier 5 is Coated with fuel catalyst. When in use, the fuel catalyst is connected to the outside of the engine. After the fuel enters the fuel catalyst, the flow channel on the honeycomb catalyst carrier divides the fuel and fully contacts the fuel catalyst. The unique material characteristics of the fuel catalyst are used to refine and catalyze the increase of fuel oil. The fuel is active, so that the fuel molecular clusters can produ...

Embodiment 2

[0055] as attached Figure 1-3 As shown, a fuel catalytic converter includes a structural main body 1, the structural main body 1 is a hollow columnar structure, the two ends of the structural main body 1 are respectively provided with a cover 2, and the cover 2 is provided with an oil pipe connection Port 23, the structural main body 1 is provided with a hollow carrier shell 3, the carrier shell 3 is filled with a fuel catalyst core 4, the fuel catalyst core 4 includes a honeycomb catalyst carrier 5, and the surface of the honeycomb catalyst carrier 5 is Coated with fuel catalyst.

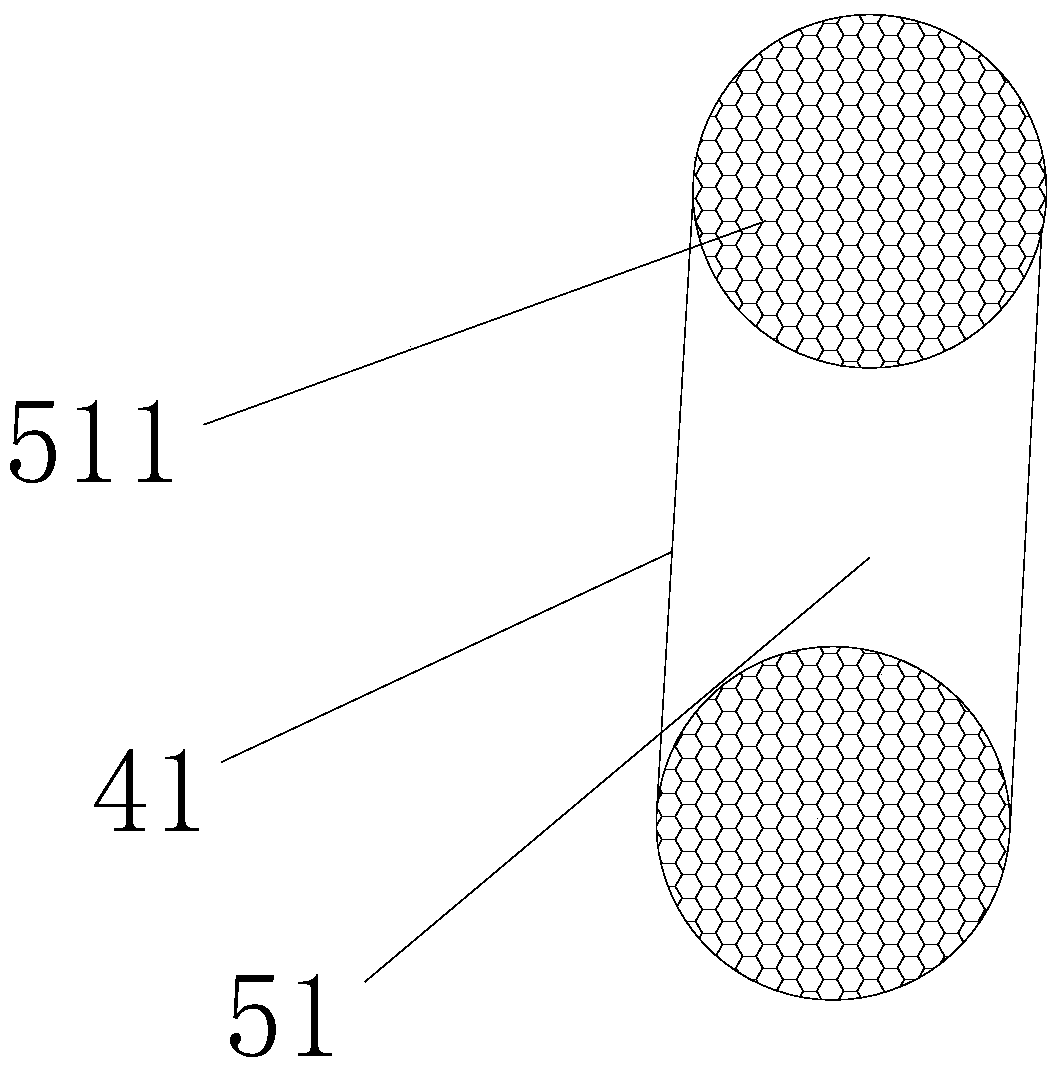

[0056] Preferably, the fuel catalyst core 4 is a honeycomb metal fuel catalyst core 41, and the honeycomb metal fuel catalyst core 41 adopts a honeycomb metal catalyst carrier 51.

[0057] Compared with Example 1, the difference is that the preparation process of the fuel catalytic core 4 is different,

[0058] The preparation process of the fuel catalytic core 4 comprises the following steps: ...

Embodiment 3

[0066] as attached Figure 1-3 As shown, a fuel catalytic converter includes a structural main body 1, the structural main body 1 is a hollow columnar structure, the two ends of the structural main body 1 are respectively provided with a cover 2, and the cover 2 is provided with an oil pipe connection The main body 1 of the port 23 is provided with a hollow carrier shell 3, and the carrier shell 3 is filled with a fuel catalytic core 4, and the fuel catalytic core 4 includes a honeycomb catalyst carrier 5, and the surface of the honeycomb catalyst carrier 5 is coated with Covered with fuel catalyst.

[0067] Preferably, the fuel catalyst core 4 is a honeycomb metal fuel catalyst core 41, and the honeycomb metal fuel catalyst core 41 adopts a honeycomb metal catalyst carrier 51.

[0068] Compared with Example 1, the difference is that the preparation process of the fuel catalytic core 4 is different,

[0069] The preparation process of the fuel catalytic core 4 comprises the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com