High-power electromagnetic induction ultraviolet germicidal lamp used directly in water

An electromagnetic induction, high-power technology, applied in the direction of irradiation, disinfection, etc., can solve the problems of large size of ultraviolet germicidal lamps, increase equipment cost, increase ultraviolet loss, etc., to reduce ultraviolet loss, reduce equipment cost, and ensure electrical insulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

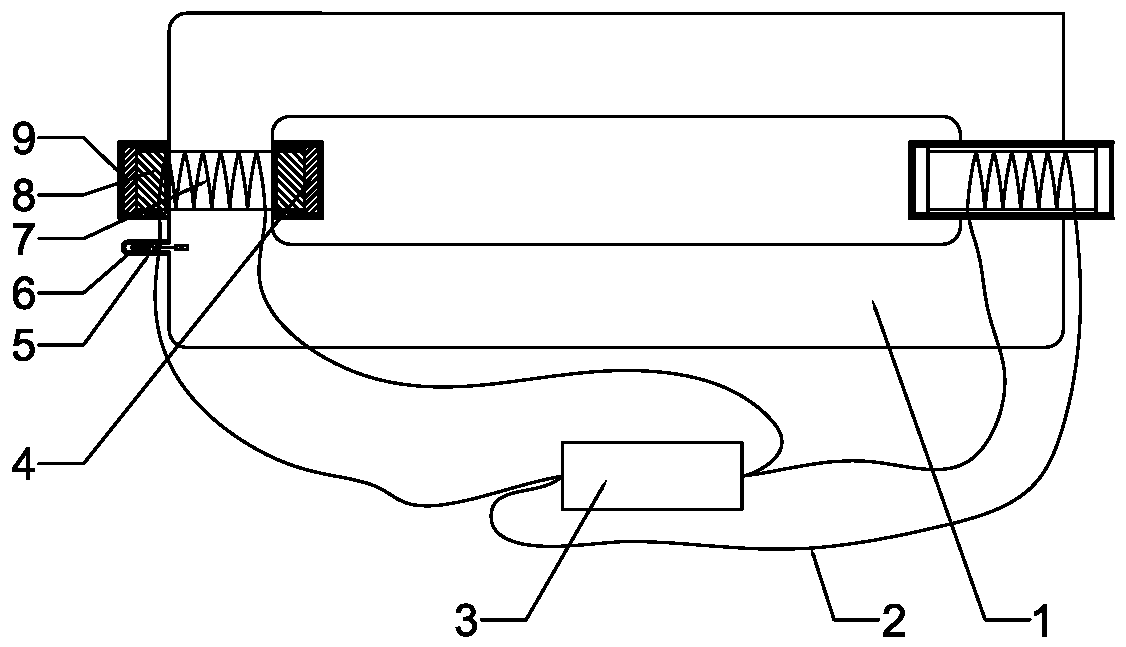

[0020] Such as figure 1 As shown, it is a high-power electromagnetic induction ultraviolet germicidal lamp used directly in water, including a glass bulb 1 with a closed structure. The glass bulb 1 is in a rectangular ring shape as a whole. The glass bulb 1 is made of quartz glass. An amalgam tube 5 with an opening facing the inner cavity of the glass bulb 1 is provided, and an amalgam 6 is arranged inside the amalgam tube 5 , and two groups of electromagnetic devices are arranged symmetrically outside the glass bulb 1, and the electromagnetic devices include a magnetic device set outside the glass bulb 1. The ring 8 and the induction coil 7 wound on the magnetic ring 8, the two sets of induction coils 7 are connected in parallel to the output end of the high-frequency generator 3 through the high temperature resistant wire 2; the magnetic ring 8 is composed of two semicircular arc cores, The outer circumference of the two semi-arc magnetic cores is provided with a clamp 4; ea...

Embodiment 2

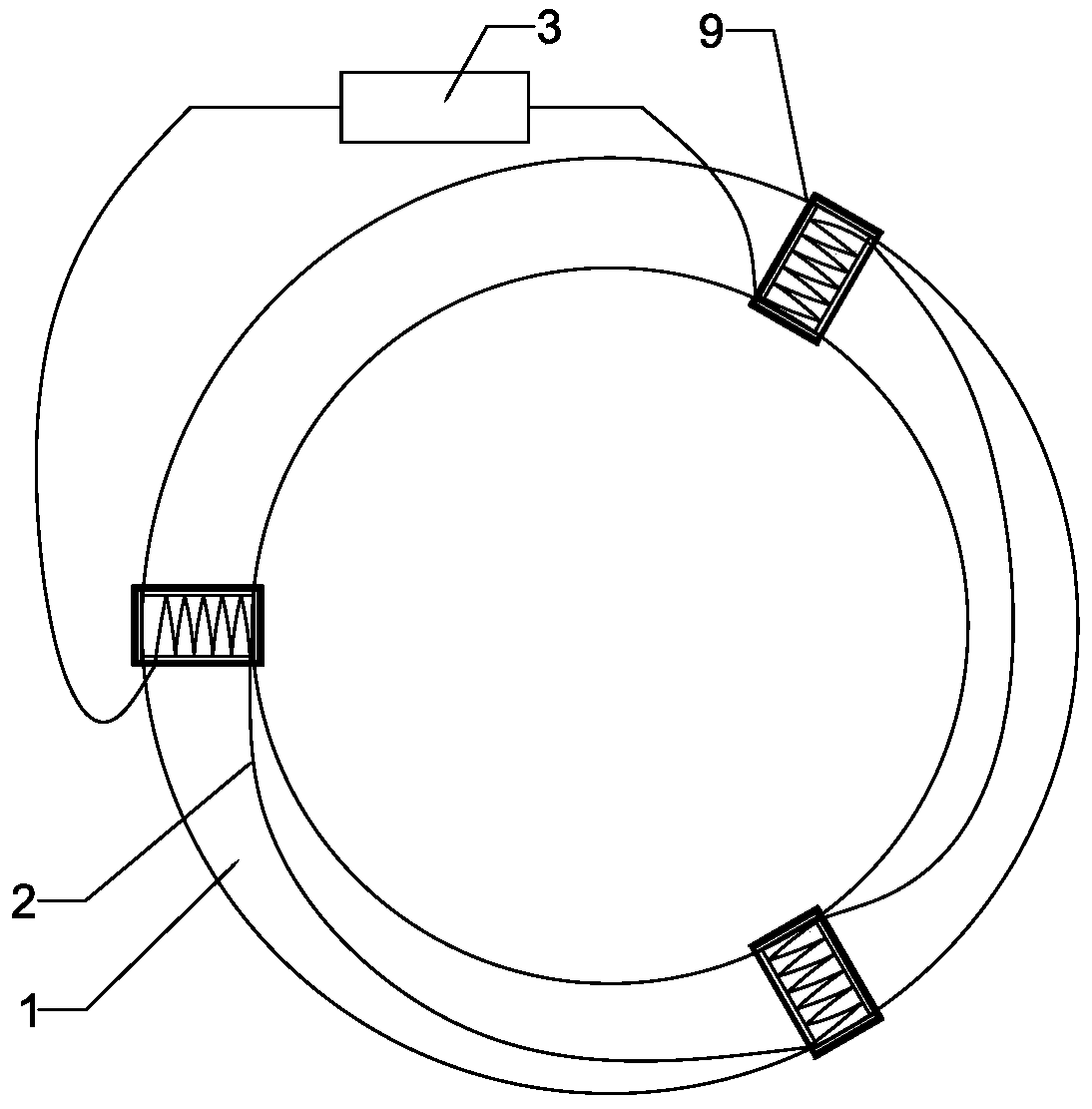

[0024] Such as figure 2 As shown, it is another kind of high-power electromagnetic induction ultraviolet germicidal lamp directly used in water. Compared with Embodiment 1, its difference is that: the glass bulb 1 is in the shape of a ring as a whole, and the electromagnetic device has three groups in the glass bulb 1 is evenly distributed along the circumferential direction, and the induction coils 7 corresponding to the three groups of electromagnetic devices are connected in series to the output end of the high-frequency generator 3 through the high-temperature resistant wire 2 .

[0025] During manufacture, nano-tin copper powder is composed of nano-scale tin powder and nano-scale copper powder, wherein the weight ratio of tin powder and copper powder is 9:1, and the proportion of nano-tin copper powder to the total weight after mixing with waterproof and heat-conducting silica gel is 25%. The waterproof and heat-conducting silicone rubber is methyl vinyl silicone rubber...

Embodiment 3

[0027] The difference from Example 1 is that when the sealing protection body 9 is manufactured, the weight ratio of the tin powder and the copper powder in the nano-tin copper powder is 8.5:1, and the nano-tin copper powder accounts for the total weight after mixing with the waterproof and heat-conducting silica gel. The ratio is 20%. The waterproof and heat-conducting silicone rubber is methyl vinyl silicone rubber. The vulcanizing agent is di-tert-butyl peroxide. It adopts two-stage vulcanization. The one-stage vulcanization is molding vulcanization. Carry out in a ventilated incubator, the vulcanization temperature is 170±5°C, and the curing time is 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com