Valve drying box

A technology for drying boxes and valves, applied in drying, drying machines, drying chambers/containers, etc., can solve problems such as rusting and affecting work efficiency, and achieve the effect of improving drying efficiency and ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means and creative features realized by the present invention easy to understand, the present invention will be further elaborated below.

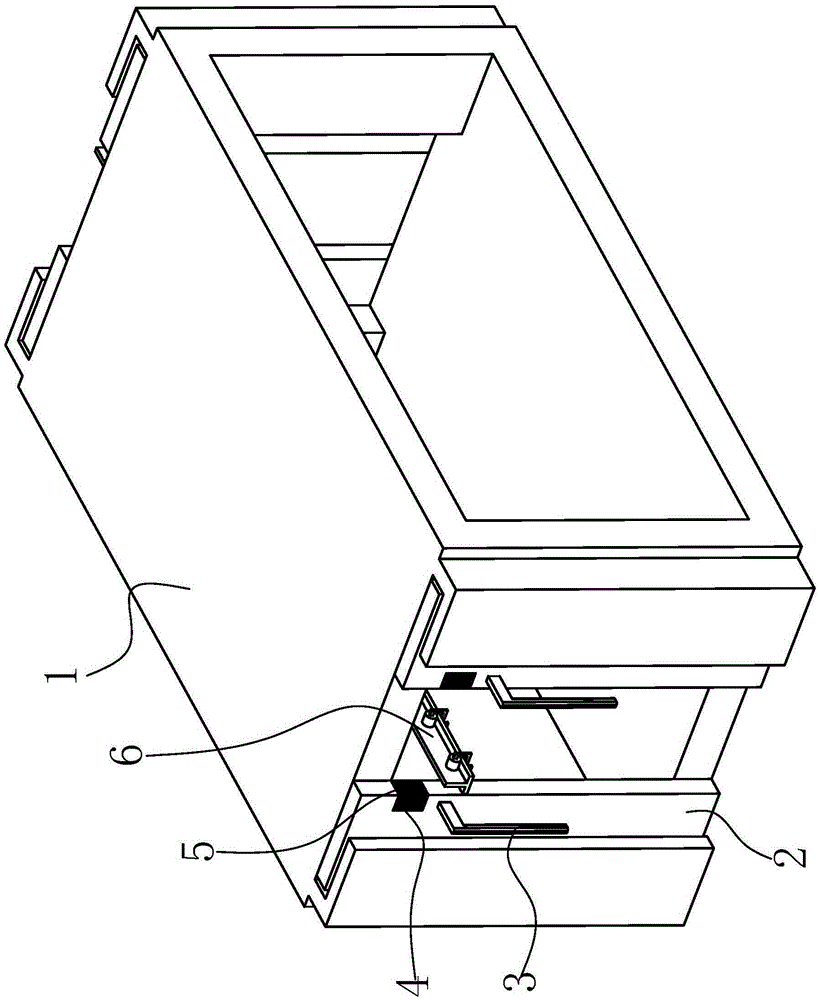

[0015] Such as Figure 1 to Figure 2 As shown, a valve drying box includes a box chamber 1, and the left and right sides of the box chamber 1 are provided with side-pull movable doors 2, and the side-pull movable doors 2 on each side are of a split type. The outer end face of the pull-type dodge door 2 is provided with L-shaped handles 3, and the handle 3 can be set longer to prevent the heat in the chamber 1 from being transferred to the end of the handle 3. The side-pull dodge door 2 Grooves 4 are provided on the side contacting with the other side pull-type movable door 2, and curtains 5 made of asbestos materials are evenly distributed in the grooves 4.

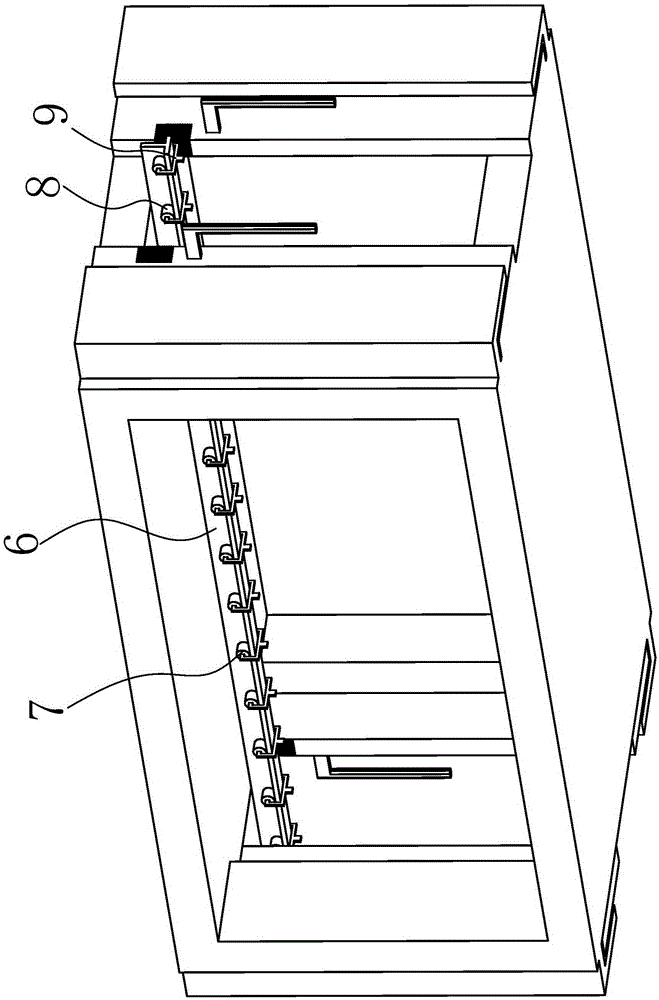

[0016] A crossbeam 6 is horizontally arranged in the chamber 1, and the crossbeam 6 is in the shape of an inverted T. Hangers 7 are evenly hung ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com