An air bearing system supporting a high-speed and small-length-diameter-ratio micro-rotor

An air bearing and aspect ratio technology, which is applied in the directions of bearings, bearings, shafts and bearings in rotating motion, can solve the problems affecting the stable rotation of the micro-rotor, the friction of the micro-rotor, and the friction of the rotor, so as to achieve stable startup, Avoid low-speed collisions and jams, and meet the effect of support requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

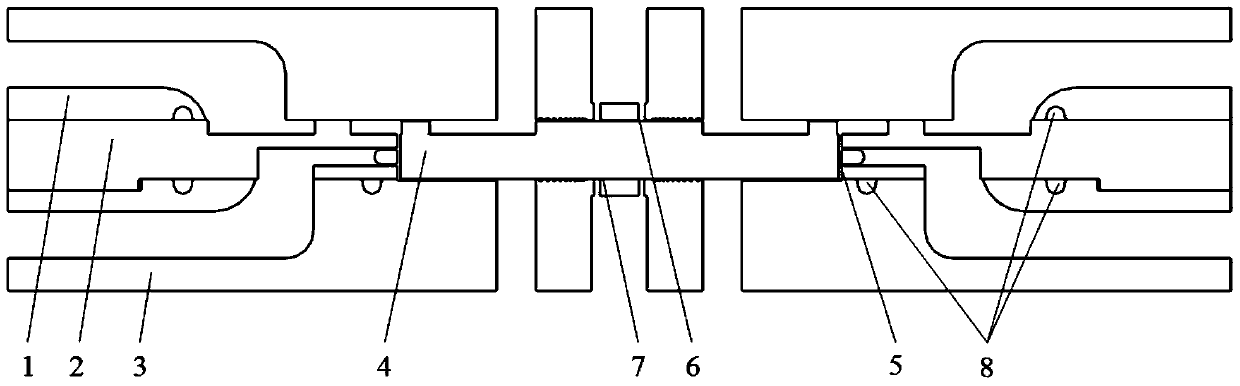

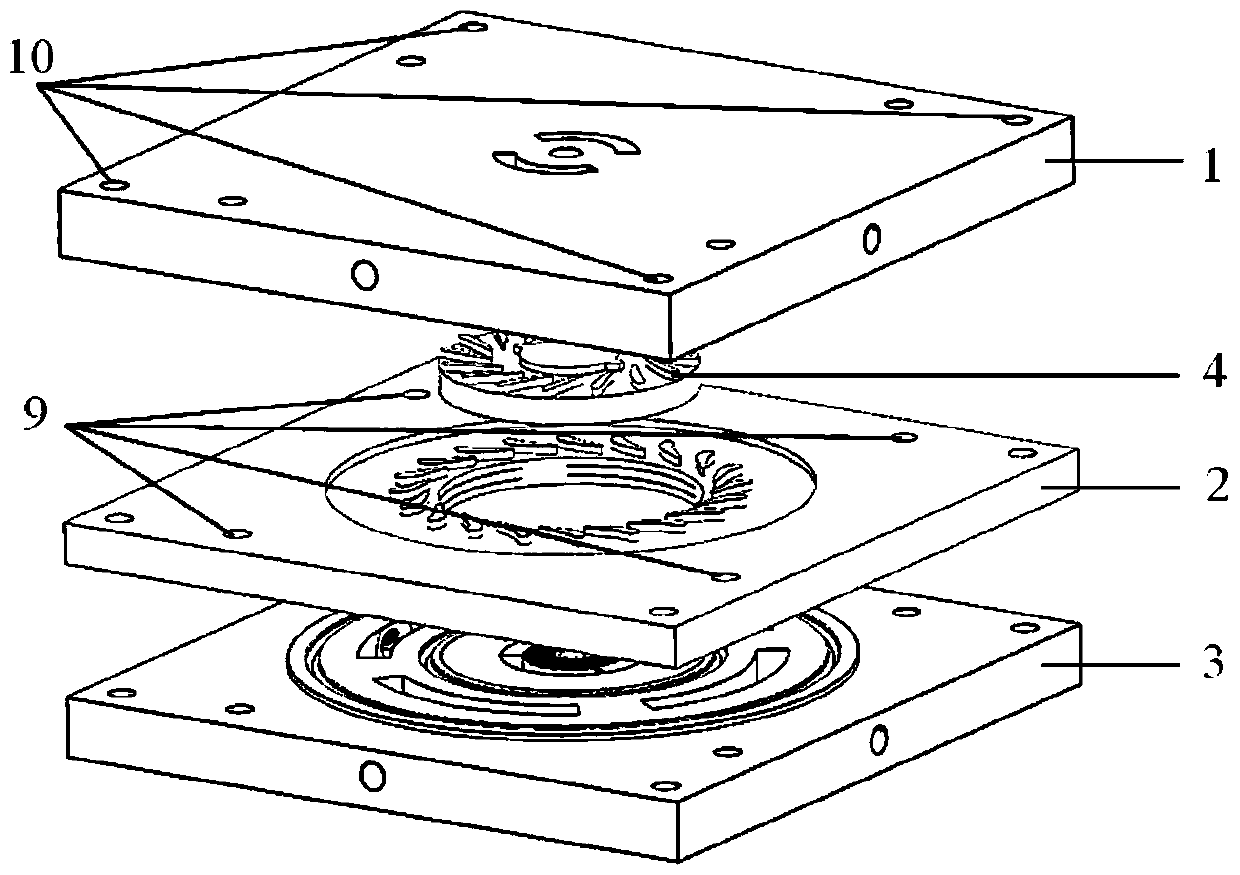

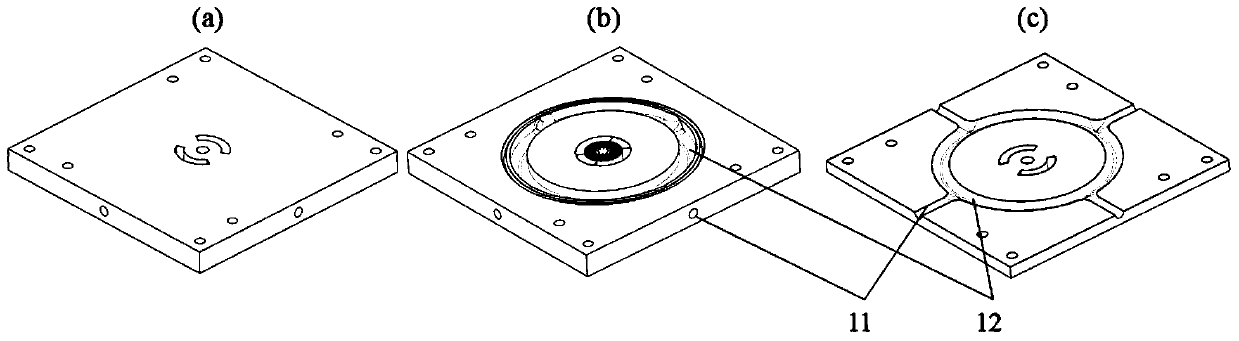

[0025] Such as figure 1 with figure 2 As shown, the main body of an air bearing system supporting a micro-rotor with high speed and small aspect ratio in the present invention includes an upper stator part 1, a middle layer stator part 2 and a lower layer stator part 3, a miniature centripetal turbine rotor 4, and a radial air bearing 5 , the front thrust air bearing 6 and the rear thrust air bearing 7. During installation, the structural parts of each layer are placed overlappingly, and the seal between the layers is realized by the sealing ring in the sealing ring groove 8, and the four positioning and pressing bolt holes 9 are evenly distributed to realize the positioning between the layers and provide the pressure of the sealing ring. Tightening force, four mounting and fixing bolt holes 10 realize the installation and fixing of the whole device....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com