Asymmetric air bearing for built-in pitching mechanism

A technology of air bearings and pitching mechanisms, applied in the field of bearings, can solve the problems of asymmetric air bearings with few structures and only in the research and development stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0021] The invention provides an asymmetrical air bearing for a built-in pitch mechanism.

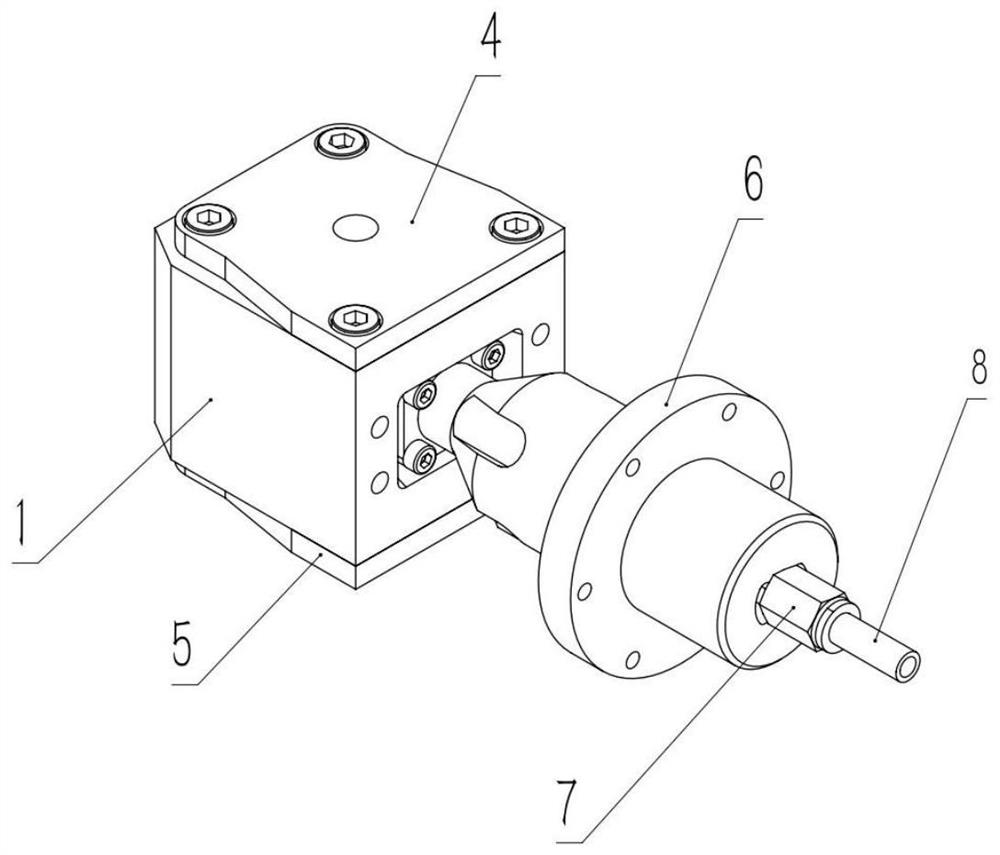

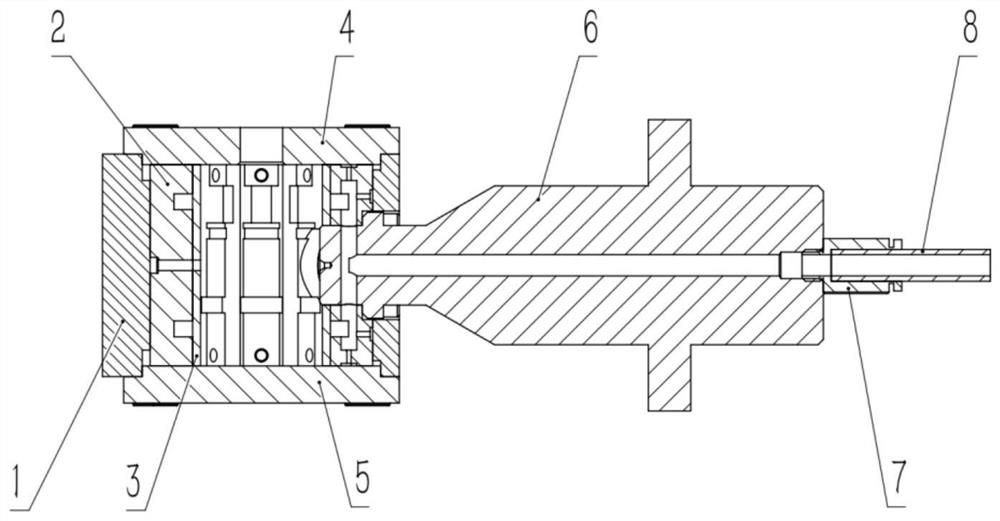

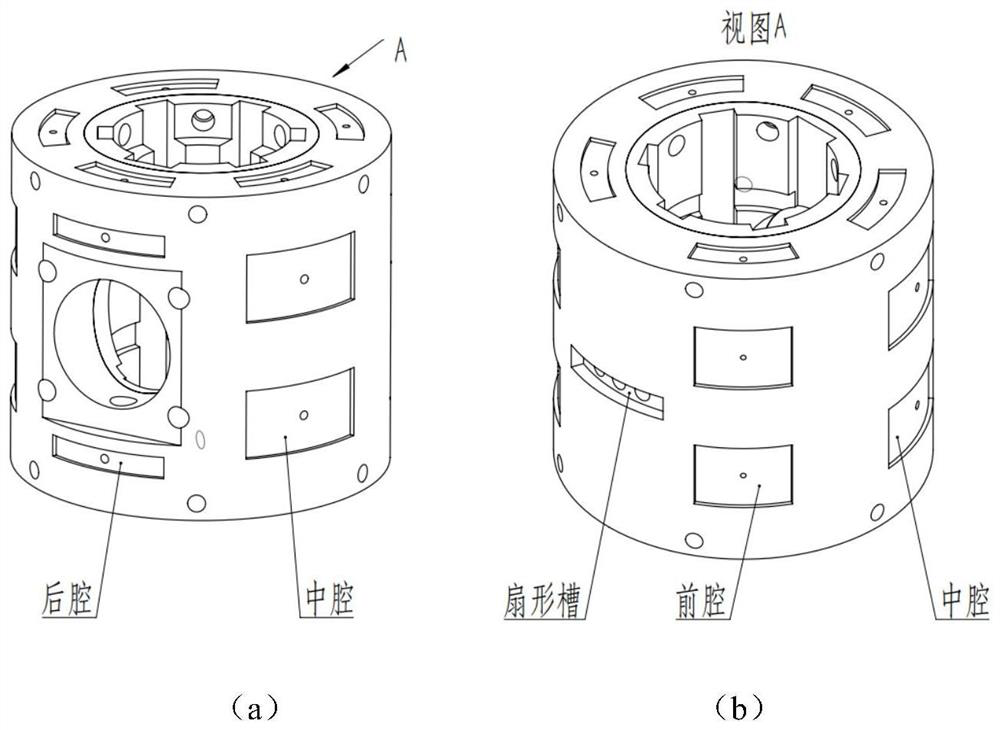

[0022] Such as figure 1 , figure 2 As shown, the system includes an air bearing and a strut 6. The air bearing includes a bearing housing 1, a bearing bush 2, a bearing stator 3, an upper end cover 4, and a lower end cover 5. The bearing bush 2 and the bearing stator 3 pass through an interference fit, and the air bearing The outside of the bearing is the bearing shell 1, the upper end cover 4 and the lower end cover 5 are respectively fixed and installed on both ends of the bearing shell 1 by bolts; one end of the bearing shell 1 has a hole for connecting the strut 6 with the air bearing, and the other end of the strut 6 is set Pneumatic connector 7, and conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com