A gdi fuel injector heated by ptc thermosensitive ceramics

A heat-sensitive ceramic and fuel injector technology, used in machines/engines, fuel injection devices, engine components, etc., can solve the problems of poor fuel atomization quality and high pollutant emissions, and achieve short heating time, high heating efficiency, The effect of good fuel injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

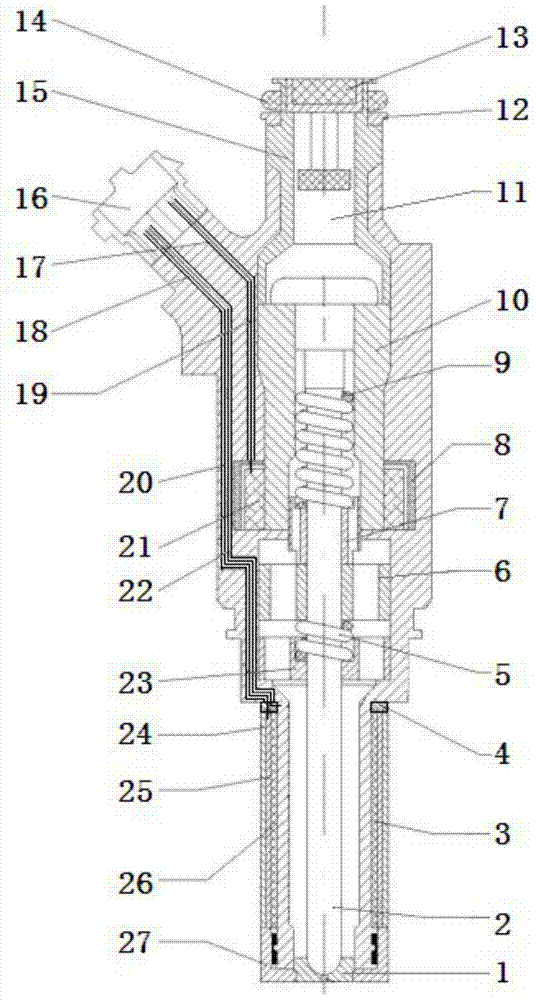

[0024] figure 1 Shown is the specific implementation of the invention utilizing the GDI fuel injector heated by PTC thermosensitive ceramics.

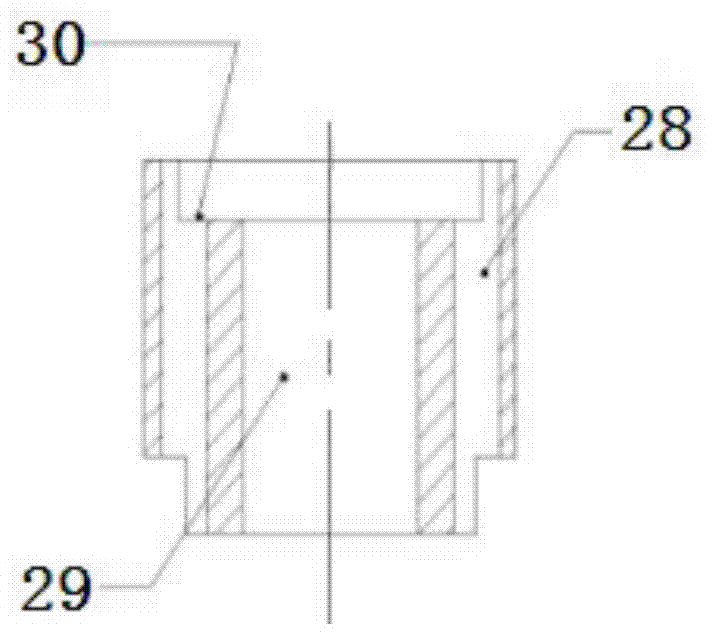

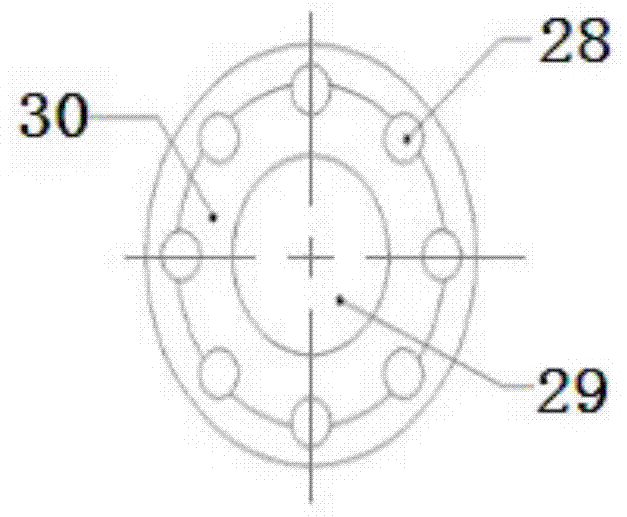

[0025] The present invention consists of a bottom plate 1, a needle valve 2, a PTC heat-sensitive ceramic tube 3, an insulating gasket 4, a buffer spring I5, an armature 6, an armature guide ring 7, a coil support 8, a buffer spring II9, a limit sleeve I10, and a cavity 11. Sealing ring limit ring 12, filter screen 13, sealing ring 14, connecting sleeve 15, harness plug 16, sleeve I17, sleeve II18, coil wire 19, positive wire 20, electromagnetic coil 21, negative wire 22, Buffer spring seat 23, insulating sheath 24, pure copper sheet 25, valve body 26, limit sleeve II 27, in which connection sleeve 15, limit sleeve I10, armature 6, buffer spring seat 23 are arranged from top to bottom In the valve body 26; the connection sleeve 15, the limit sleeve I10 and the cavity 11 in the valve body 26 are provided with buffer spring II9, armatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com