Mobile gantry frame and its construction method in the construction of large cantilever cover beam

An in-construction and gantry technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as affecting construction progress, potential safety hazards, and uncontrollable factors, reducing turnaround time, structural stability and safety, Improve the effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

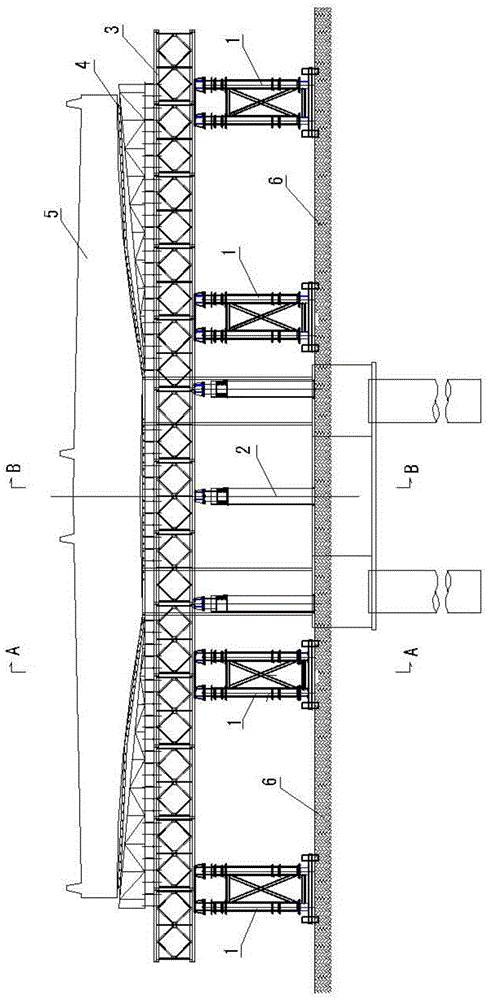

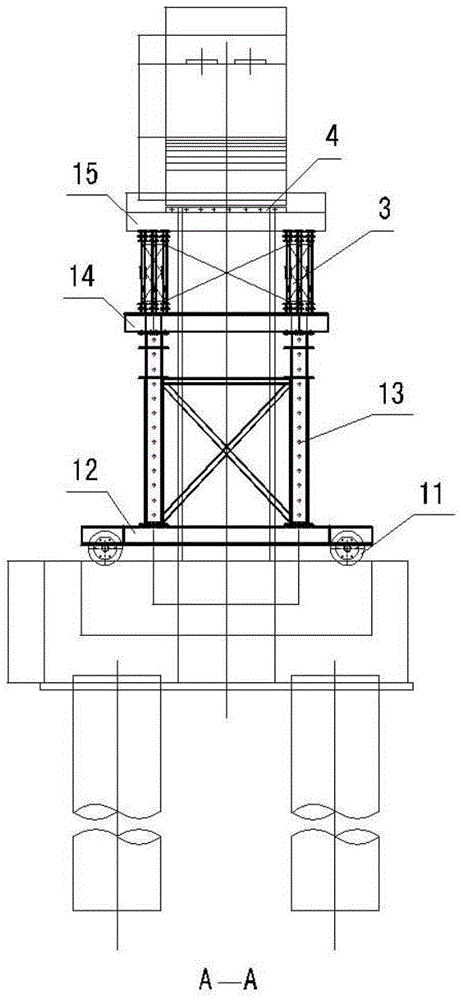

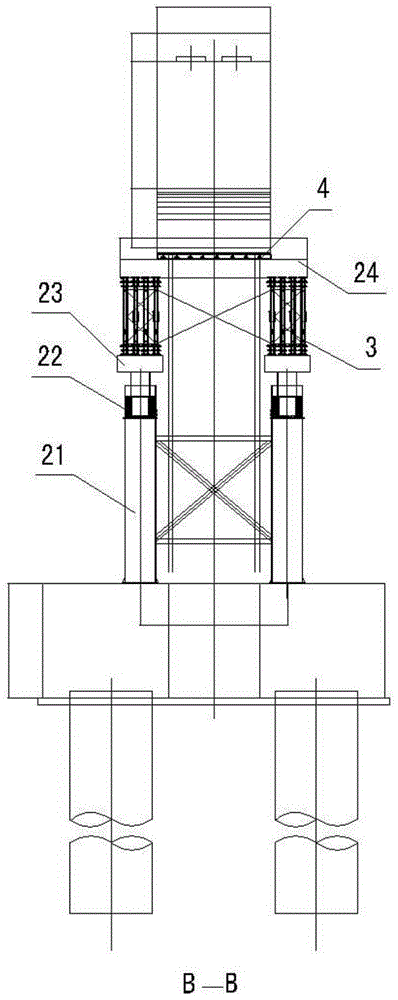

[0021] see figure 1 , figure 2 with image 3 1. The mobile gantry system in the construction of the large cantilever cover beam in this embodiment is to set the mobile gantry system for the construction of the large cantilever cover beam 5: the mobile gantry system includes three units, which are respectively the left unit, the middle unit and the right side The unit; the left unit and the right unit have a symmetrical structure, and are respectively composed of two sets of independently set movable gantry 1, and the distance between the two groups of movable gantry 1 is the width of the normal traffic lane 6; The mobile gantry 1 uses movable universal wheels as casters; the intermediate unit 2 uses a spiral tube 21 as a support column, and a sand box 22 is set on the top of the spiral tube 21, and an intermediate unit distribution beam 23 is set on the sand box 22. The Bailey beam 3 used for laying the bottom formwork 4 of the cover beam is supported on the movable gantry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com