A Construction Method of Fiber Reinforced Lower Sealing Layer of Semi-rigid Base Asphalt Pavement

A technology of semi-rigid base and asphalt pavement, applied in the direction of on-site coagulation pavement, roads, roads, etc., can solve the problem of unsatisfactory waterproof and crack resistance, the service life of semi-rigid base asphalt pavement does not reach the design life, reduce and other problems, to achieve the effect of strong airtightness, preventing the flow of asphalt, increasing tensile strength and fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

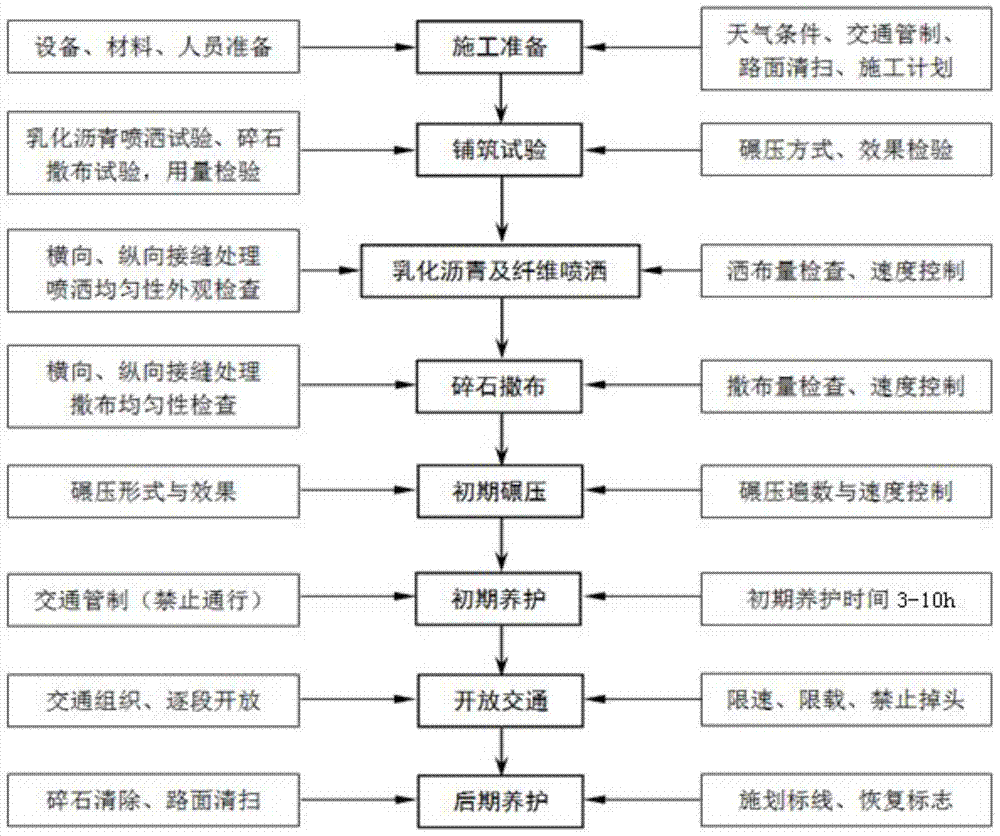

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1: road section A, secondary road

[0059] Clean up the garbage, sundries, loose aggregates and obstacles on the surface of the semi-rigid base course in section A;

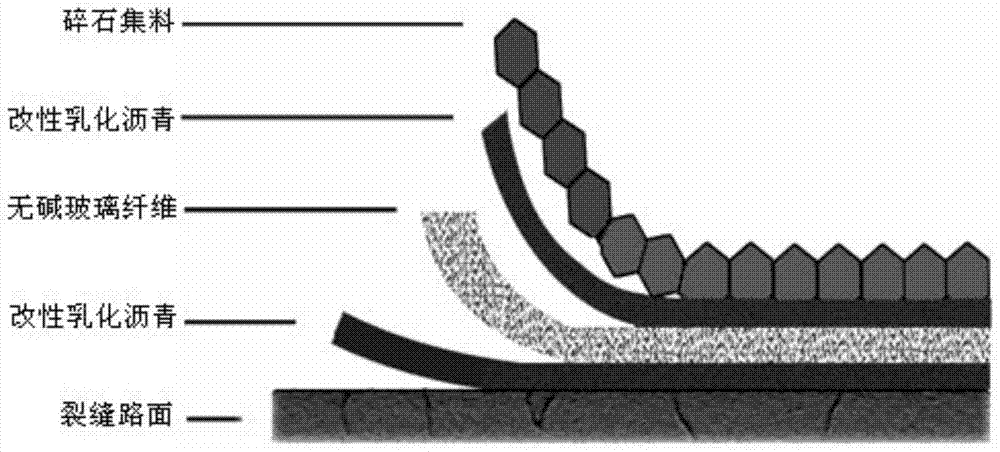

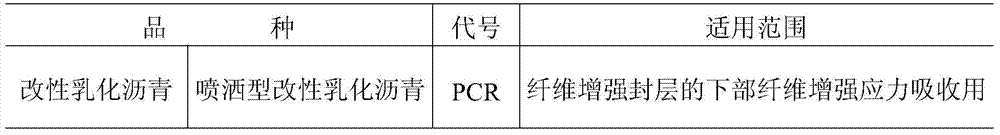

[0060] Control the construction speed of the fiber seal spreader at 3.6km / h, and simultaneously apply the emulsified asphalt of the lower layer, the alkali-free glass fiber of the middle layer and the upper layer Emulsified asphalt, in which the asphalt spraying temperature is 72°C, the spraying amount of the lower layer of emulsified asphalt and the upper layer of emulsified asphalt are controlled at 0.7kg / m2 and 0.6kg / m2 respectively, and the spreading amount of alkali-free glass fiber in the middle layer is controlled at 75g / m2, and They are all composed of non-alkali glass fiber segments with a length of 7cm; start the gravel spreader and keep it at a distance of 10m from the fiber seal spreader, and immediately spray the emulsified asphalt and the non-alkali glass fiber within 1min. Spread...

Embodiment 2

[0062] Embodiment 2: road section B, first-class road

[0063] Conduct semi-rigid base-level strength testing and treatment on road section B, and clean up garbage, sundries, loose aggregates and obstacles on the surface of the semi-rigid base;

[0064] Control the construction speed of the fiber seal spreader at 3.8km / h, and simultaneously apply the emulsified asphalt of the lower layer, the alkali-free glass fiber of the middle layer and the upper layer Emulsified asphalt, wherein the asphalt spraying temperature is 70°C, the spraying amount of the lower layer of emulsified asphalt and the upper layer of emulsified asphalt are controlled at 0.73kg / m2 and 0.63kg / m2 respectively, and the spreading amount of alkali-free glass fiber in the middle layer is controlled at 100g / m2, and They are all composed of non-alkali glass fiber segments with a length of 8cm; start the gravel spreader and keep it at a distance of 10m from the fiber seal spreader, and within 1.5min after emulsifi...

Embodiment 3

[0066] Embodiment 3: road section C, expressway

[0067] Conduct semi-rigid base course strength testing and treatment on road section C, and clean up garbage, sundries, loose aggregates and obstacles on the surface of the semi-rigid base course;

[0068]Control the construction speed of the fiber seal spreader at 3.8km / h, and simultaneously apply the lower layer of emulsified asphalt, the middle layer of non-alkali glass fiber and the upper layer to the surface of the semi-rigid base layer of section C that has completed surface cleaning by running the fiber seal layer spreader Emulsified asphalt, wherein the asphalt spraying temperature is 70°C, the spraying amount of the lower layer of emulsified asphalt and the upper layer of emulsified asphalt are controlled at 0.71kg / m2 and 0.66kg / m2 respectively, and the spreading amount of alkali-free glass fiber in the middle layer is controlled at 110g / m2, and They are all composed of non-alkali glass fiber segments with a length of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com