Polyvinyl chloride/polyurethane alloy cable material and preparation method thereof

A technology of polyvinyl chloride and polyvinyl chloride resin, applied in the field of cable materials, can solve the problems of shortened life of wire and cable sheath layers, low mechanical strength, difficult extrusion molding, etc., and achieve easy continuous and stable production and fatigue life Excellent, easily processable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

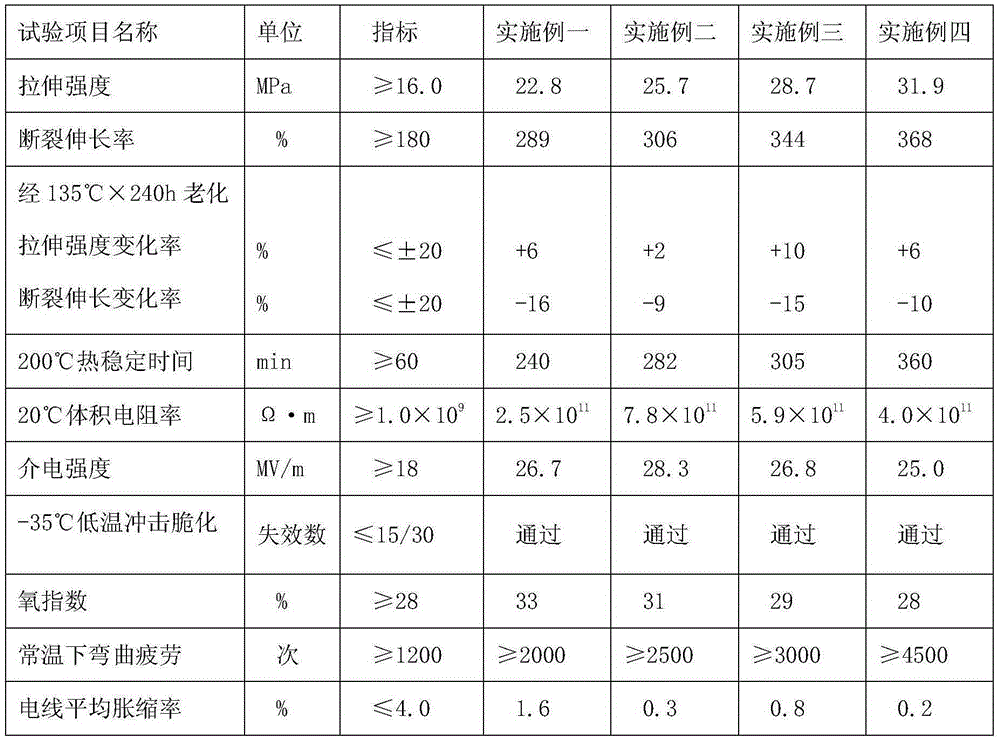

Examples

Embodiment 1

[0029] Put 60 parts by weight of polyvinyl chloride resin, 50 parts by weight of plasticizer, and 10 parts by weight of stabilizer in a high-speed mixer and stir at high speed, while stirring, heat up to 80-90 ° C, add 0 parts by weight of filler, 5 parts by weight of resistor Fuel agent, 1.0 parts by weight of processing aid, continue to heat up and stir at high speed until the material temperature is 105-110 ° C, then add 40 parts by weight of polyurethane, 0.5 parts by weight of antioxidant and stir at low speed for 2-4 minutes, put the mixture into Stable in a low-temperature mixer or cooling tank for 15-30 minutes, and finally add a feeder to a twin-screw mixing extruder for mixing, plasticizing and granulating, and obtain the finished product after drying, wherein the twin-screw mixing extruder The four temperature zones of the machine are: feeding section 130°C, mixing section 150°C, granulation section 165°C, machine head 170°C.

[0030] Wherein: the polyvinyl chloride...

Embodiment 2

[0032] Different from Example 1, the parts by weight of each component in the raw material are different. In this example, the following parts by weight are included: 50 parts by weight of polyurethane, 50 parts by weight of polyvinyl chloride resin, 20 parts by weight of plasticizer parts, 5 parts by weight of a stabilizer, 1 part by weight of a flame retardant, 40 parts by weight of a filler, 1.5 parts by weight of an antioxidant, and 3.0 parts by weight of a processing aid.

Embodiment 3

[0034] Different from Example 1, the parts by weight of each component in the raw material are different. In this example, the following parts by weight are included: 60 parts by weight of polyurethane, 40 parts by weight of polyvinyl chloride resin, 15 parts by weight of plasticizer parts, 8 parts by weight of a stabilizer, 2 parts by weight of a flame retardant, 80 parts by weight of a filler, 2.0 parts by weight of an antioxidant, and 6.0 parts by weight of a processing aid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com