Method for preparing building materials by virtue of sludge pyrolyzation

A sludge and pyrolysis technology, applied in applications, household appliances, ceramic products, etc., can solve the problems of less attention to the utilization of sludge pyrolysis residual coke, high energy consumption cost of sludge composting, and high incineration operation cost, reaching The effect of light weight, saving building energy consumption and good compressive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

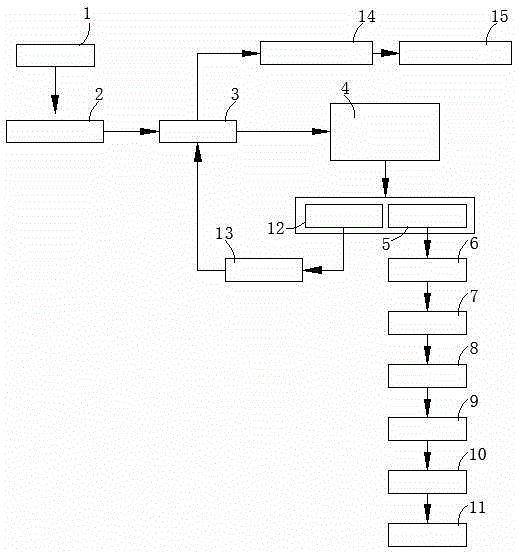

[0025] see figure 1 , a kind of method utilizing sludge pyrolysis to prepare building material, comprises the following steps:

[0026] Step 1, drying the papermaking sludge 1 in a radiant solar dryer 2 until the moisture content is lower than 35%;

[0027] Step 2, the papermaking sludge dried in step 1 is evenly sent to the direct contact drying chamber 3, dried by the flue gas of the system, and sent to the volumetric pyrolyzer 4, the pyrolysis temperature is controlled at 400 °C, and the sludge Combustible gas 11 and sludge charcoal 5 are produced by pyrolysis; combustible gas 12 is sent to the combustion chamber 13 for combustion, and the high-temperature flue gas generated by combustion is sent to the drying chamber 3 to preheat and dry the sludge; the waste gas produced by drying and cooling After the flue gas is sent into the gas purification equipment 14, enters the chimney 15 after purification;

[0028] Step 3, sending the high-temperature sludge charcoal 5 prepare...

Embodiment 2

[0031] Referring to Example 1, this example is a further preferred example of the content of Example 1. Therefore, the method further includes, taking 30-50 parts of papermaking sludge and 20-40 parts of municipal sludge as pyrolysis raw materials, according to The steps in Example 1 were carried out to prepare building materials by pyrolysis.

[0032] A method for preparing building materials by pyrolysis of sludge, comprising the following steps:

[0033] Step 1, 30 parts of papermaking sludge and 40 parts of municipal sludge are placed in a convection solar dryer 2 to dry until the moisture content is lower than 35%;

[0034] Step 2, send the sludge treated in step 1 into the indirect contact dryer 3, dry it with a heat source, and send it to the rotary kiln pyrolyzer 4. The pyrolysis temperature is controlled at 700°C, and the sludge is pyrolyzed to produce combustible gas 12 and sludge charcoal 5; the combustible gas 12 is sent to the combustion chamber 13 for combustion...

Embodiment 3

[0038] Referring to Example 1, this example is a further preferred example of the content of Example 1. Therefore, the method further includes taking municipal sludge as a pyrolysis raw material and performing pyrolysis according to the steps in Example 1 to prepare building materials.

[0039] A method for preparing building materials by pyrolysis of sludge, comprising the following steps:

[0040] Step 1, the municipal sludge 1 is placed in a conductive solar dryer 2 to dry until the moisture content is lower than 35%;

[0041] Step 2: send the sludge treated in step 1 into the indirect contact dryer 3, dry it with a heat source, and send it into the tubular pyrolyzer 4. The pyrolysis temperature is controlled at 600°C, and the sludge is pyrolyzed to produce combustible gas 12 and sludge charcoal 5; the combustible gas 12 is sent into the combustion chamber 13 for combustion, and the high-temperature flue gas generated by the combustion is sent into the indirect contact drye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com