Apparatus and method for sequential melting and refining in a continuous process

A process chamber, heat treatment technology, used in chemical instruments and methods, lighting and heating equipment, silicon compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

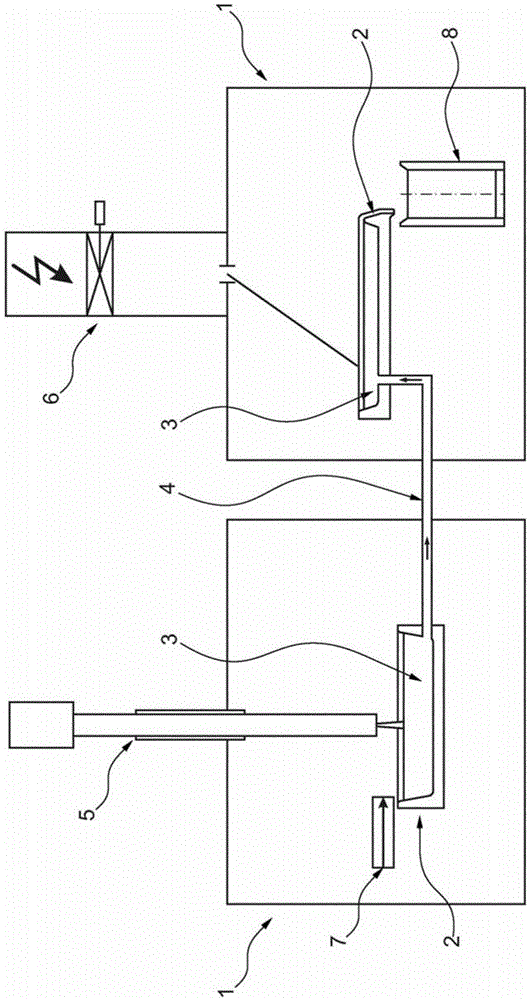

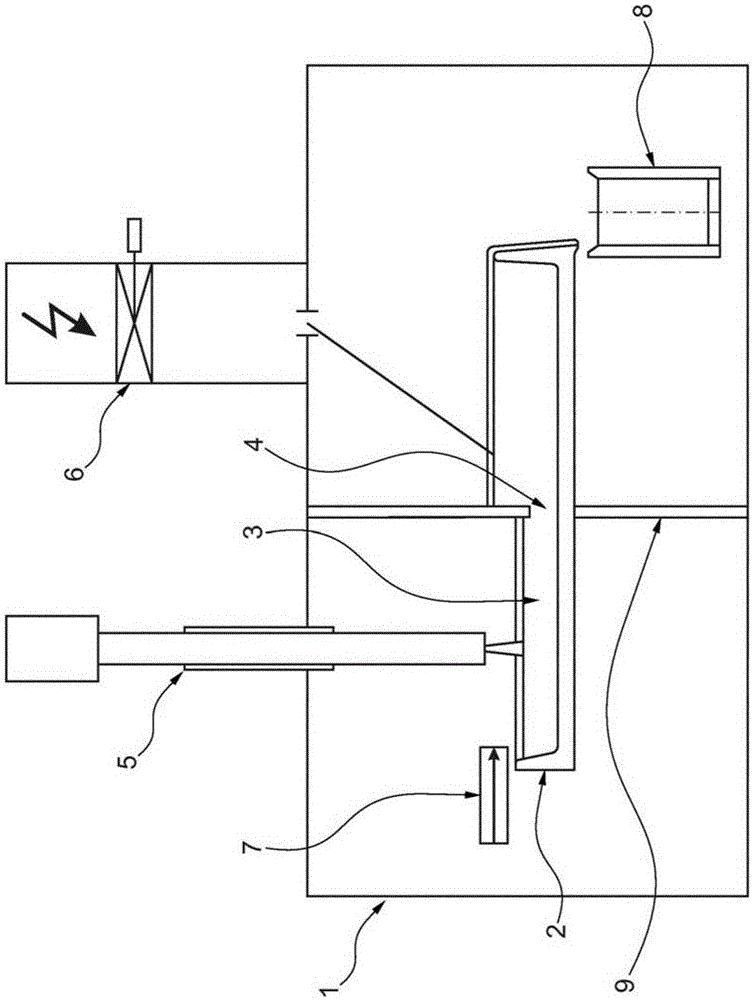

[0049] figure 1 A device according to the invention is shown comprising two process chambers 1 and two process containers 2 . As can be seen in the figure, each treatment chamber 1 contains a treatment vessel 2 . The material 3 to be treated present in the treatment container needs to be liquid, at the latest when it enters the conveying channel 4 . The two heat sources 5 and 6 shown are different. The heat source 5 may be, for example, a plasma burner and the heat source 6 may be, for example, an electron beam gun. It can be seen from the figure that the height of the liquid material in the second processing chamber is higher than that in the first processing chamber. Therefore, the liquid material has to be raised in the transfer channel 4 . This is caused by a pressure difference, since the plasma burner operates in the low pressure range in this embodiment, while the electron beam gun operates in a vacuum. Arrows show the flow direction of the liquid material. The li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com