Backrest structure for a vehicle seat, and vehicle seat

A technology for vehicle seats and backrests, applied in vehicle seats, special positions of vehicles, seat frames, etc., can solve problems such as increased damage and adapters that cannot be easily assembled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

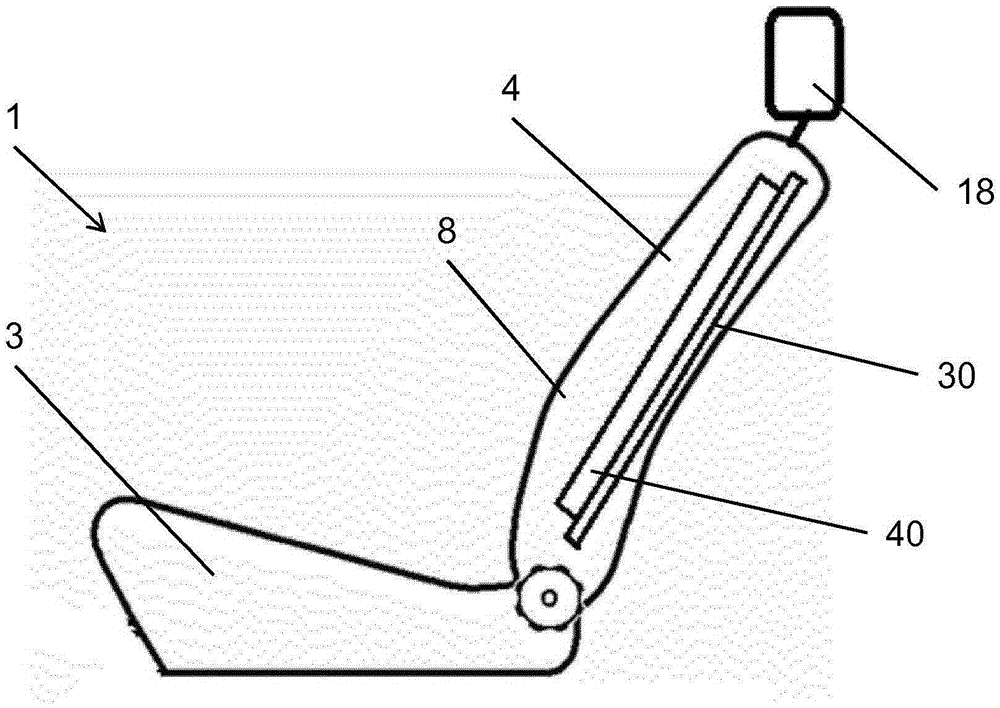

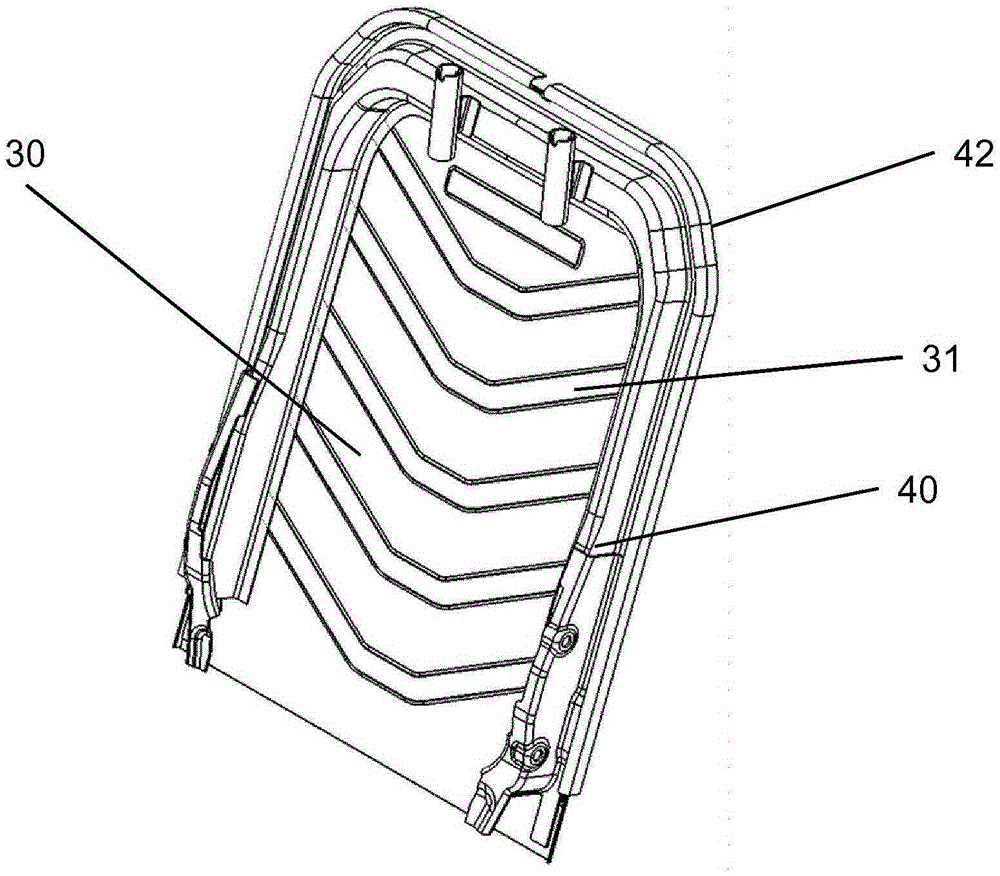

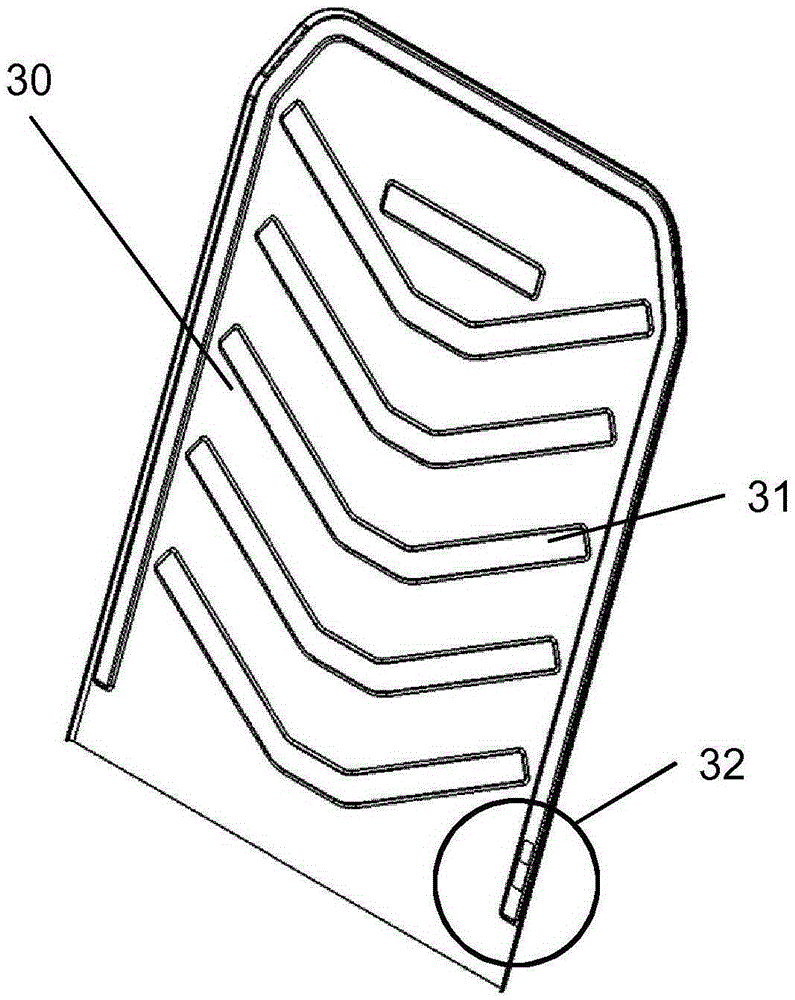

[0041]A vehicle seat 1 for a motor vehicle, in this case a rear seat, has a seat component 3 and a backrest 4 which can be fitted to the seat structure 3 and is adjustable in terms of inclination . However, the vehicle seat 1 may also be a front seat. The backrest 4 comprises a backrest frame 40 and a base plate 30 configured as a planar object. The back frame 40 and base plate 30 are welded together, preferably by laser welding, to form the back structure.

[0042] In this case, the substrate 30 has a material thickness of approximately 0.35 millimeters. In this case, the base plate 30 comprises ribs and ribs 31 and is still intended to be considered planar. In this case, the backrest frame 40 has a material thickness of approximately 1.5 mm. Other material thicknesses of the backrest frame 40 are also conceivable, in particular between 0.8 mm and 4 mm.

[0043] The arrangement of the vehicle seat 1 in the vehicle and its usual direction of travel define the directional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com