Weighing control management system of cement in bulk

A control management, bulk cement technology, applied in the direction of total factory control, total factory control, electrical program control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

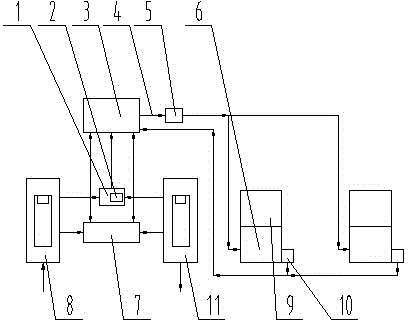

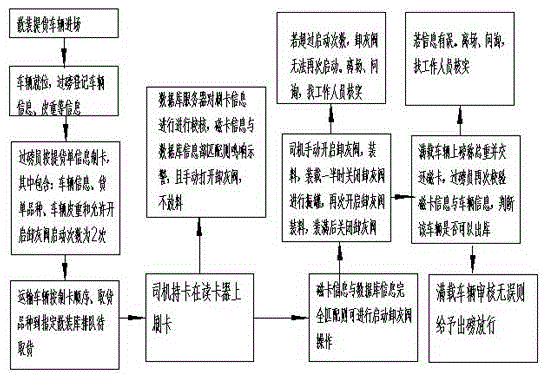

[0016] Such as figure 1 , 2 As shown, the present invention consists of a magnetic card reader 1, a magnetic card 2, a database server 3, a group of communication optical cables 4, a PLC programmable controller 5, a group of electric actuators 6, a weighing staff terminal 7, an entrance truck scale 8, a A set of bulk cement storage 9, a set of card readers 10 and an export truck scale 11, a set of magnetic card reader 1 is connected to the database server 3 through a set of communication optical cables 4, and the terminal 7 of the weigher is connected to the database through a set of communication optical cables 4 The server 3 is connected, the database server 3 is connected with the PLC programmable controller 5 through a group of communication optical cables 4, the PLC programmable controller 5 is connected with a group of electric actuators 6 through a group of communication optical cables 4, and a group of card readers 10 are connected through A set of communication opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com