Gravity deformation compensation device for optical element

A technology of gravity deformation and optical components, which is applied in the direction of photolithography process exposure devices, microlithography exposure equipment, etc., can solve the problems affecting the imaging quality of the optical system, and achieve the effect of reducing the difficulty of structural design, reducing coupling, and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further explained with specific embodiments below, but it is not intended to limit the protection scope of the present invention.

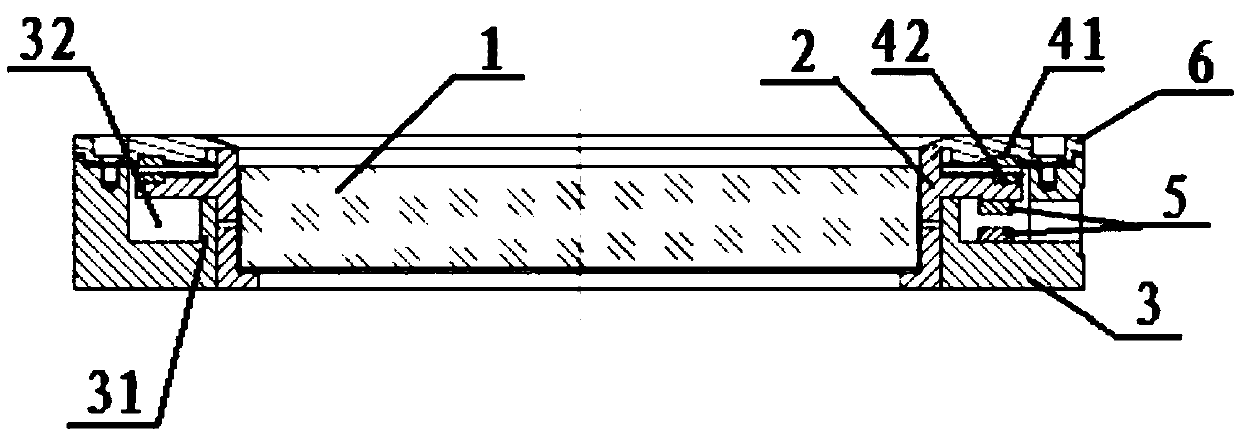

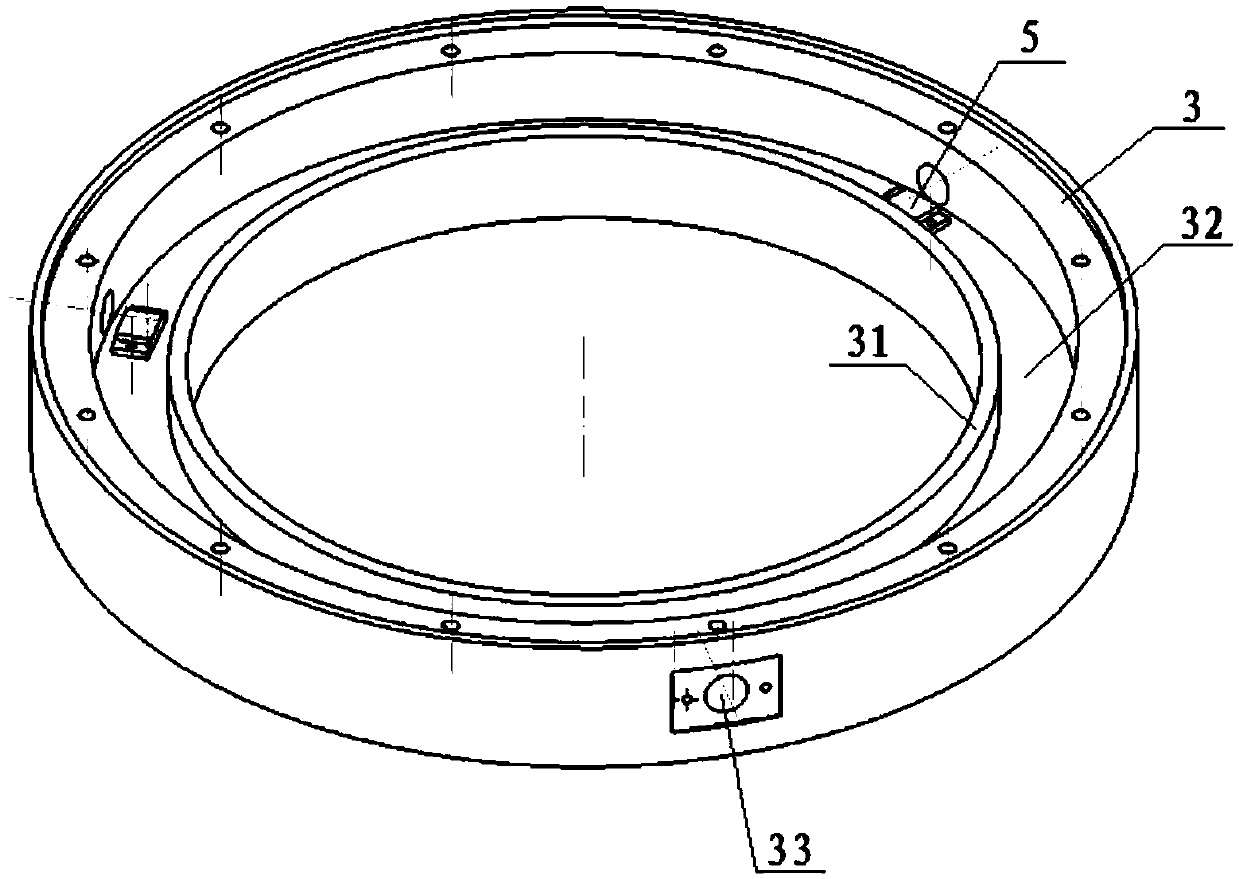

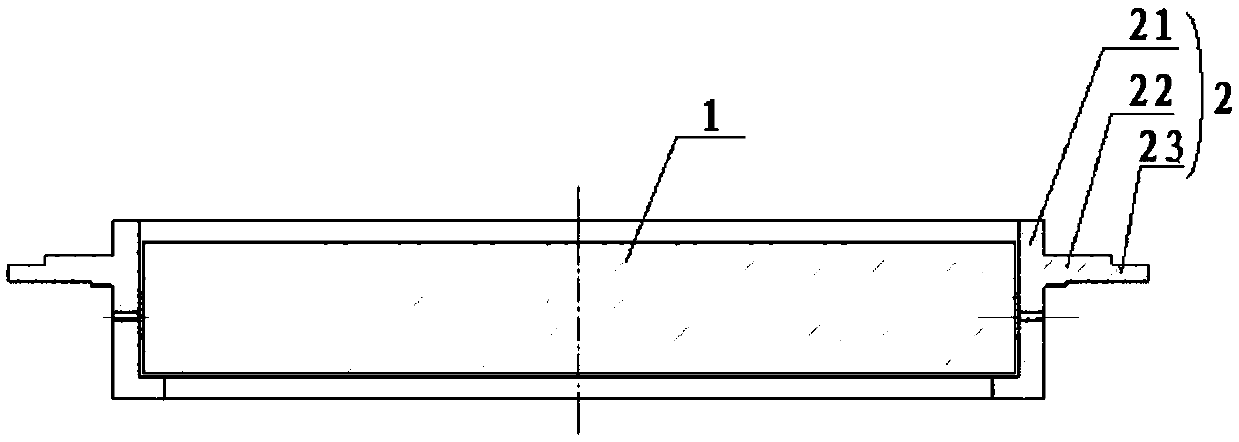

[0031] In order to compensate the rotationally symmetric aberrations introduced by the gravity due to the high-precision support of the optical elements in the lithographic projection objective lens, the rotationally symmetric aberrations are mainly Power terms and spherical aberrations, see figure 1 , the present embodiment provides a kind of gravitational deformation compensation device for optical elements, including: outer mirror frame 3, deformable mirror frame 2, upper cover plate 6, first annular electromagnet 41 and second annular electromagnet 42, see figure 2 , an upwardly extending support platform 31 is provided on the inner periphery of the outer mirror frame 3, and the width of the support platform 31 is about 3-5mm. The blue interface presses the deformable mirror frame 2 into the outer mirror f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com