Touch and liquid crystal display integration module

A liquid crystal display and integrated module technology, which is applied in optics, instruments, electrical digital data processing, etc., can solve the problems of limited manufacturers or merchants, unfavorable development, and high threshold, so as to simplify the production process and reduce adhesion The effect of loosening and optimizing product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further illustrate the present invention below in conjunction with accompanying drawing.

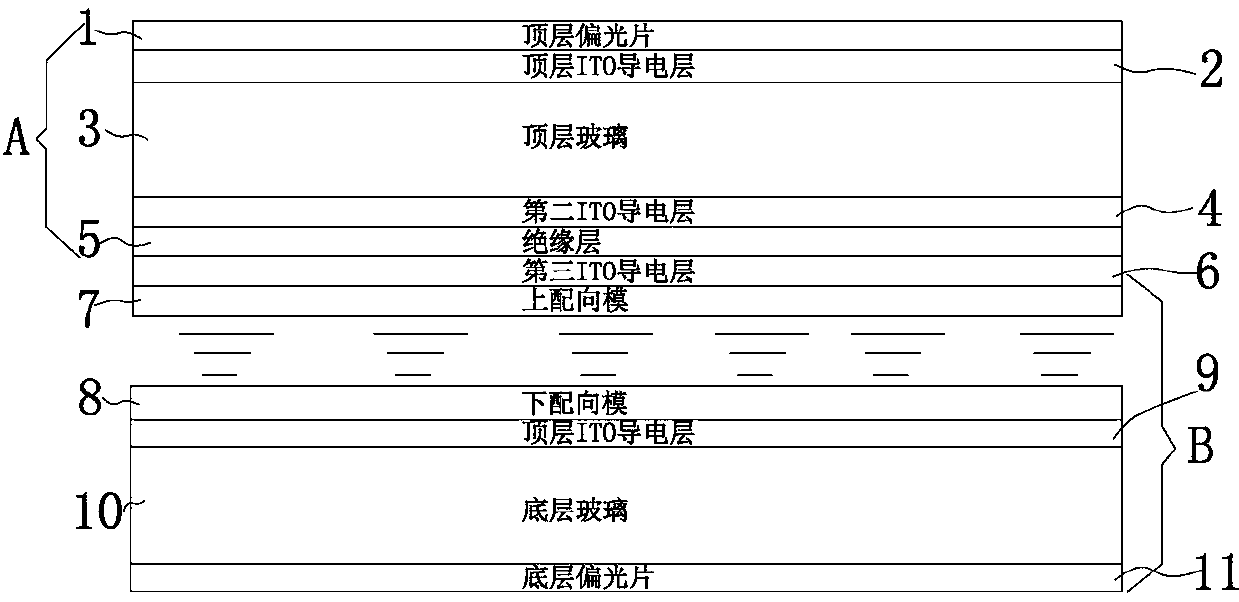

[0019] Such as figure 1 It shows a specific embodiment of the present invention, a touch and liquid crystal display integrated module, including a top polarizer 1, a top ITO conductive layer 2, a top glass 3, a touch liquid crystal group, and a bottom ITO conductive layer arranged in sequence from top to bottom 9. Bottom glass 10 and bottom polarizer 11; wherein, the touch liquid crystal group includes a second ITO conductive layer 4, an insulating layer 5, a third ITO conductive layer 6, and a liquid crystal layer, and the second ITO conductive layer 4 and the first The insulating layer 5 is arranged between the three ITO conductive layers 6, and the liquid crystal layer is arranged at the lower end of the third ITO conductive layer 6; the liquid crystal layer includes an upper alignment film 7 and a lower alignment film 8, and the upper alignment film There is a certain distanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com