Forced seal valve capable of conducting eccentric double-spherical-angle stroke operation

A technology of forced sealing and double spherical surfaces, which is applied in the direction of valve devices, cocks including cut-off devices, engine components, etc., can solve the problem of accelerating the wear of the sealing surface of the ball and the sealing surface of the valve seat, the inability to guarantee the sealing performance of the valve, and the absence of eccentric double spherical surfaces, etc. problems, to achieve the effect of reducing mutual wear, saving maintenance time, and improving sealing specific pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

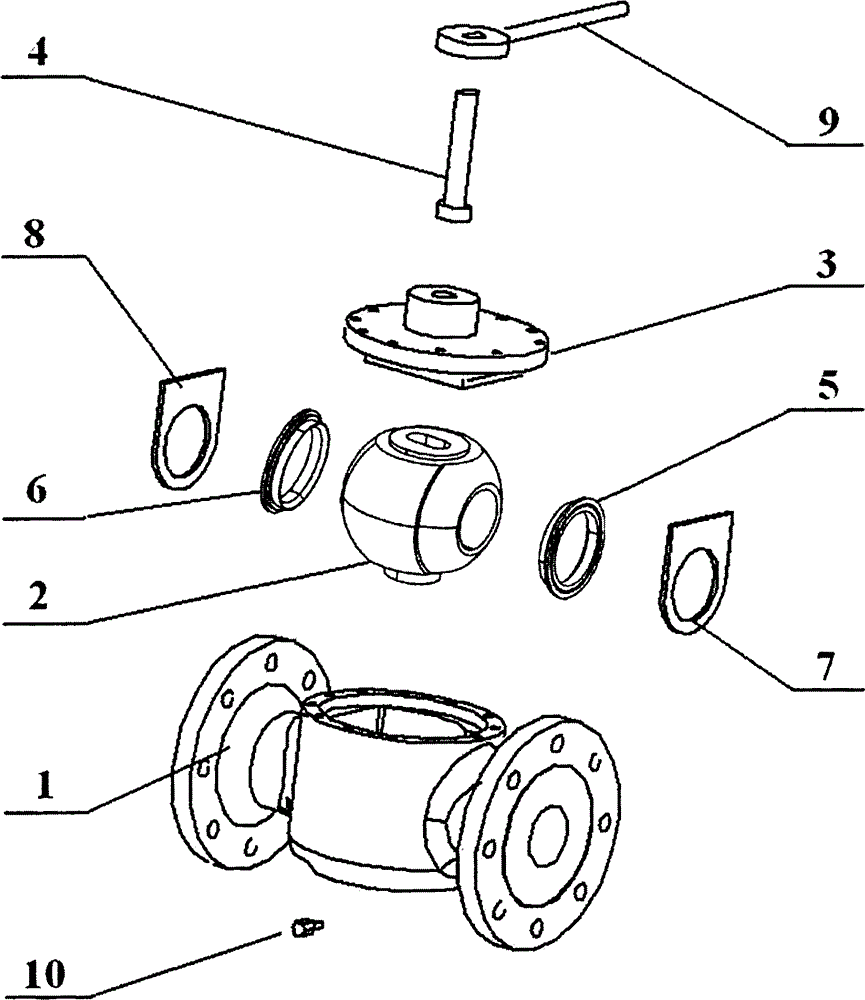

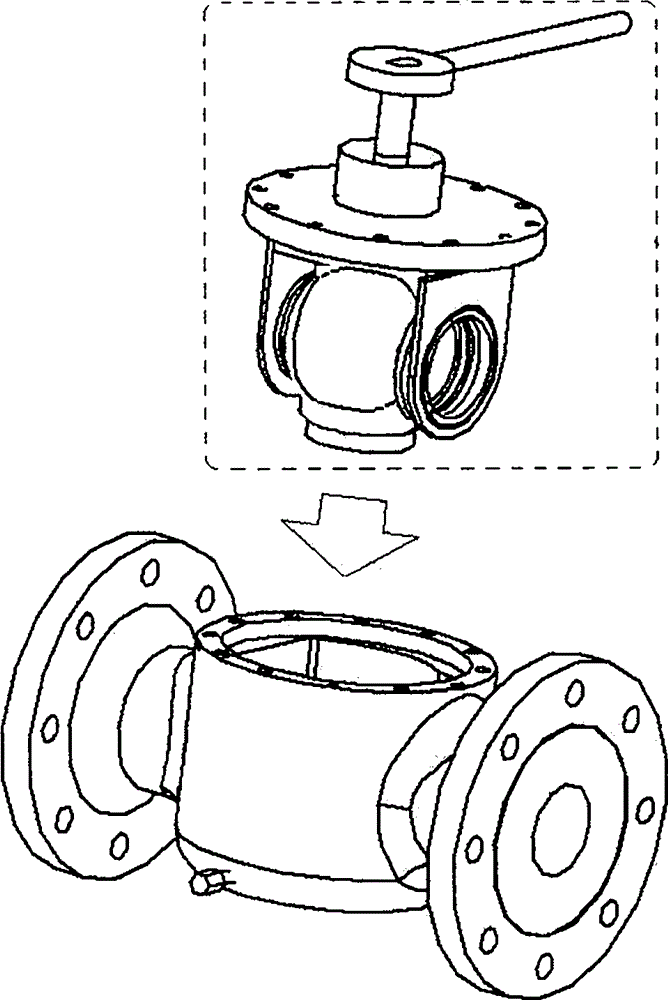

[0014] A forced seal valve with eccentric double spherical angular stroke operation, its main components include: valve body 1, opening and closing member 2, valve cover 3, valve stem 4, downstream valve seat 5, upstream valve seat 6, downstream valve seat support plate 7. Upstream valve seat support plate 8, operating mechanism 9, blowdown valve 10. Such as figure 1 shown.

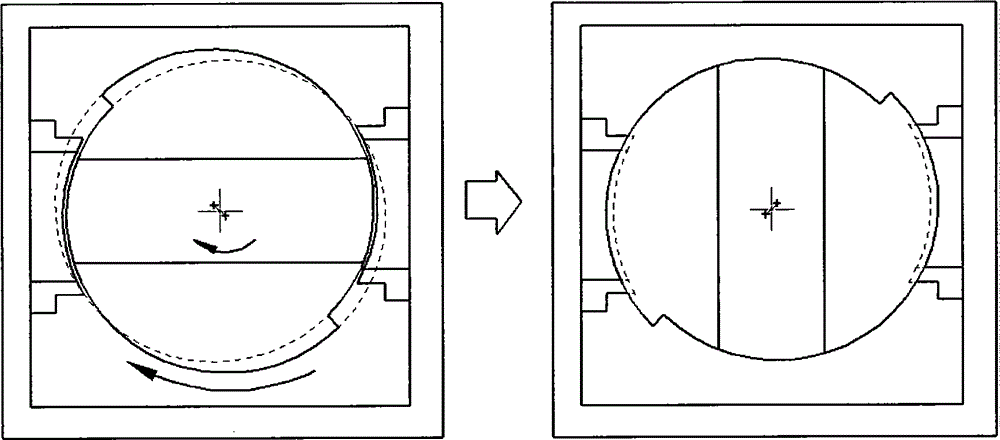

[0015] The opening and closing part 2 is connected with the valve stem 4, and the opening and closing part 2 is driven to rotate by rotating the valve stem 4 to change the relative relationship between the flow path of the opening and closing part 2 and the diameters of the downstream valve seat 5 and the upstream valve seat 6. The relationship thus achieves the purpose of opening and closing the medium. When the flow passage area of the opening and closing member 2 is 100% connected with the diameter area of the downstream valve seat 5 and the upstream valve seat 6, the valve is in the fully open p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com