A kind of weathering steel transmission tower

A transmission tower and weathering steel technology, applied in towers, building types, buildings, etc., can solve the problems of transmission tower materials and energy waste, poor node anti-corrosion performance, node corrosion, etc. Corrosion ability, effect of reducing adsorption ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

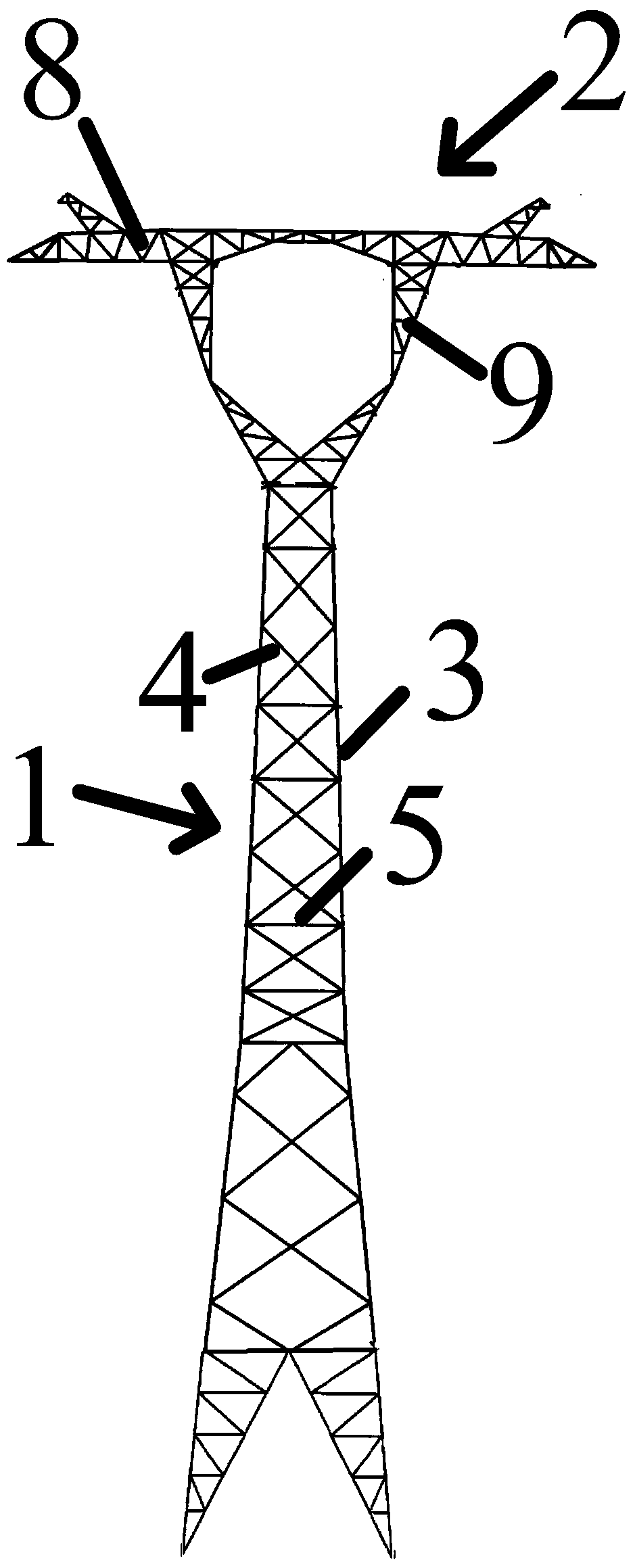

[0049] Such as figure 1 As shown, a weather-resistant steel transmission tower, the transmission tower is provided with a tower body 1 vertically arranged, a tower head 2 arranged horizontally on the upper end of the tower body 1 and a transmission wire arranged on the tower head 2,

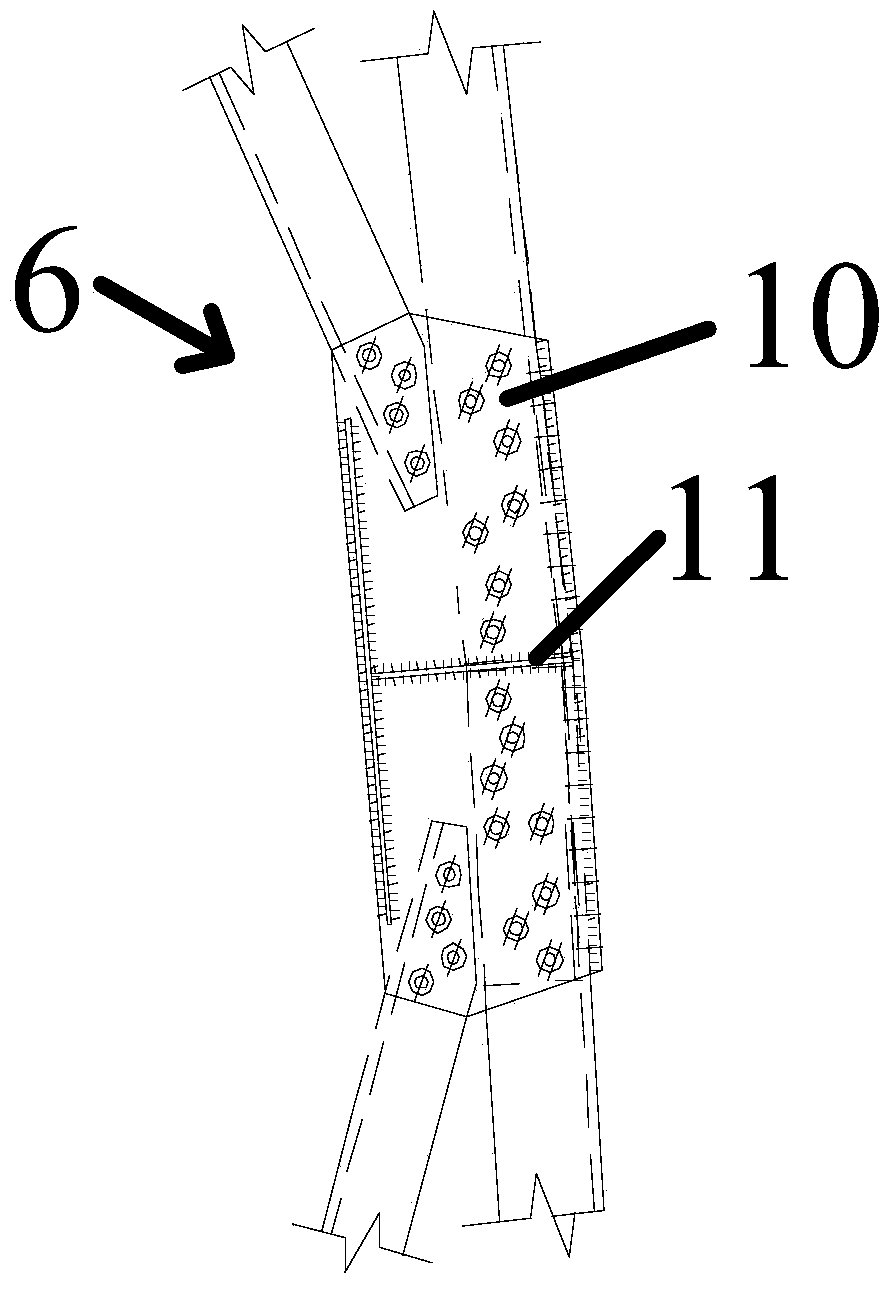

[0050] Such as figure 2 As shown, the tower body 1 is a frame structure formed by staggered connection of angle steel main material 3, angle steel oblique material 4 and angle steel horizontal material 5 vertically arranged with the angle steel main material 3, and the angle steel main material 3 and angle steel oblique The material 4 is connected through the gusset plate assembly 6;

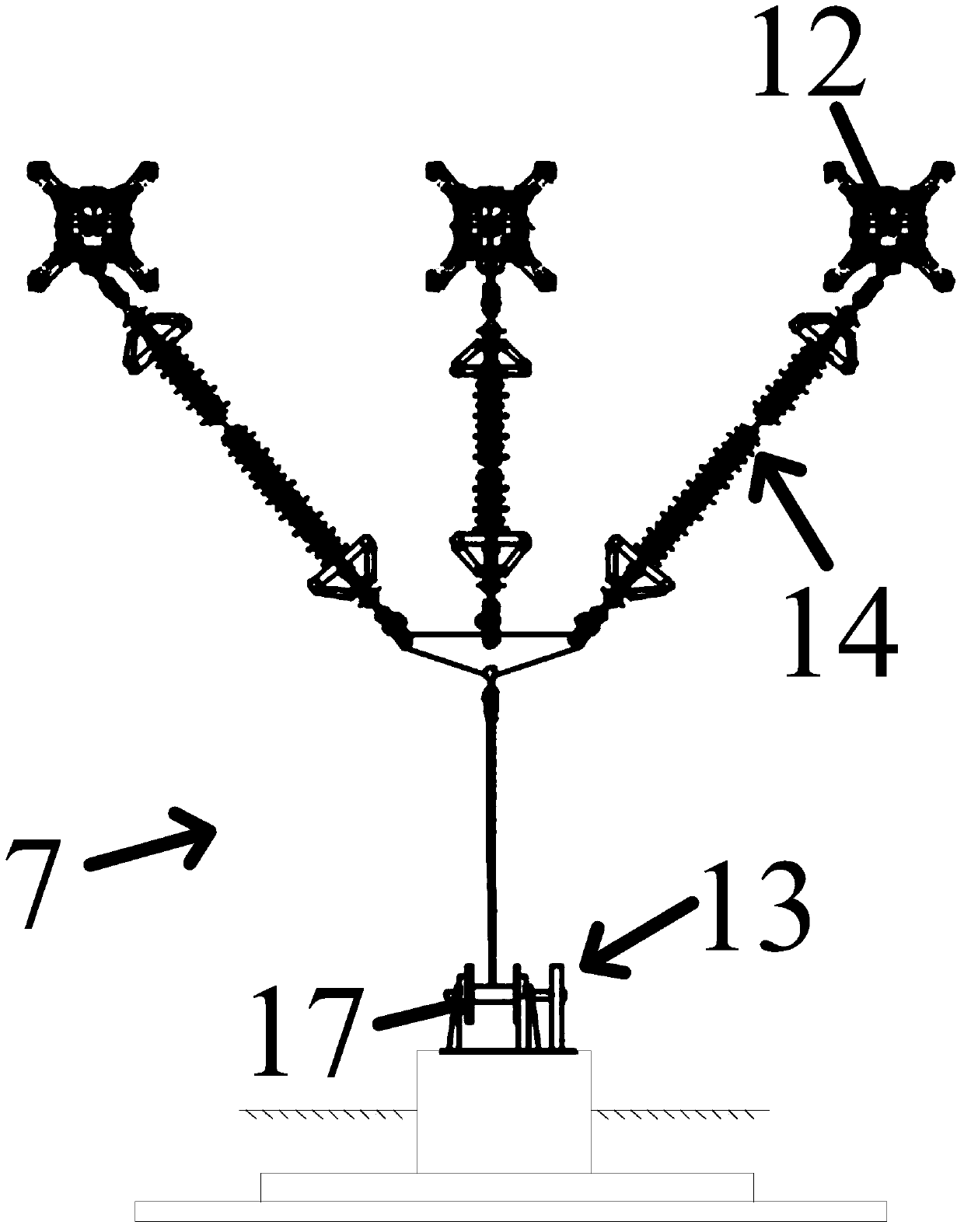

[0051] Such as image 3 As shown, the wire anti-dancing device 7 is provided on the transmission wire.

[0052] Such as figure 1 As shown, the tower head 2 is provided with horizontally arranged cross arms 8, and support vertical beams 9 arranged symmetrically on both sides of the tower body 1 perpendicular to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com