Integrated prefabricated pump station glass fiber reinforced resin concrete tube

A technology of glass fiber and reinforced resin is applied in the field of glass fiber reinforced resin concrete cylinder of integrated prefabricated pump station, which can solve the problems of excavation construction, easy damage and low rigidity, so as to improve construction reliability, The effect of saving construction period and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

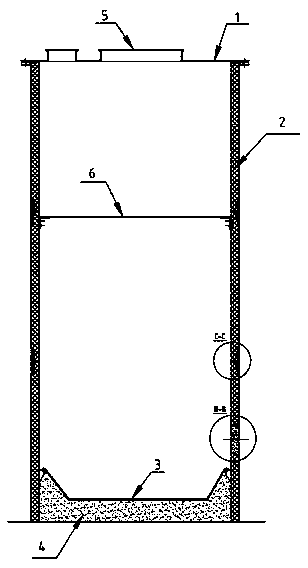

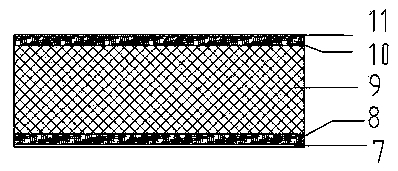

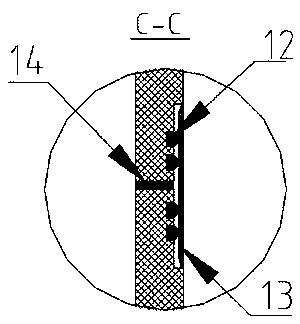

[0020] refer to figure 1 , an integrated prefabricated pumping station glass fiber reinforced resin concrete cylinder, including a cylinder body 2, a head 1 and a bottom cover 3, the cylinder body 2 is formed by connecting multiple cylinder units, the cylinder has a composite layer structure, and the cylinder is made of resin Concrete parts, the inner wall of the cylinder is provided with a glass fiber reinforced plastic anti-seepage layer 7 and an inner structural layer 8, the anti-seepage layer 7 and the inner structural layer 8 are made of unsaturated polyester resin and glass fiber winding or coating, the thickness of the glass fiber reinforced plastic anti-seepage layer is preferably 1.2-1.5mm, the thickness of the inner structure layer of FRP is confirmed according to the cylinder diameter and working conditions.

[0021] refer to figure 2 The outer wall of the cylinder is provided with an outer structural layer 10 and a wear-resistant layer 11. The outer structural la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com