A kind of coating film material for tarpaulin card strip and preparation method thereof

A coating film and coating technology, applied in textiles and papermaking, can solve the problems of reducing the service life of the tarpaulin, affecting the appearance and operation, and reducing the performance of the tarpaulin, so as to improve the resistance to external pollution and erosion, and improve the operation speed. and convenience, the effect of reducing loose yarn and thread loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a kind of preparation method as above-mentioned coating film material for novel tarpaulin strip, comprising the following steps:

[0046] (1) Prepare the anti-wicking base cloth: spread the anti-wicking base cloth to form an anti-wicking base cloth layer, and then send it to the finishing roller for heating;

[0047] (2) Coating PVC coating: the anti-wicking base cloth layer front in step (1) is coated with the PVC coating slurry that is mixed with binder, obtains the first PVC coating, on the anti-wicking base The back side of the cloth layer is coated with PVC coating slurry mixed with binder to obtain the second PVC coating, which is sent to the first oven to gel the PVC coating slurry; then the first PVC coating Coating PVC coating slurry on the surface to obtain the third PVC coating, which is sent to the second oven for drying to gel the PVC coating slurry; finally calendering, edge trimming, and large volume;

[0048] (3) surf...

Embodiment 1

[0051] A new type of coating film for tarpaulin strips, comprising an anti-wicking base cloth layer, a first PVC coating coated on the front of the anti-wicking base cloth layer, and a first PVC coating coated on the back of the anti-wicking base cloth layer Two PVC coatings, a third PVC coating coated on the surface of the first PVC coating, and a polyurethane printing layer coated on the surface of the second PVC coating.

[0052] Wherein, the first PVC coating and the second PVC coating are formed by coating a PVC coating slurry doped with a binder; the third PVC coating is formed by coating a PVC coating slurry .

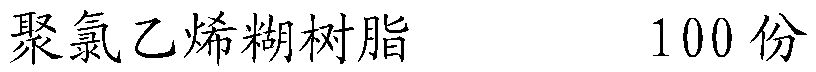

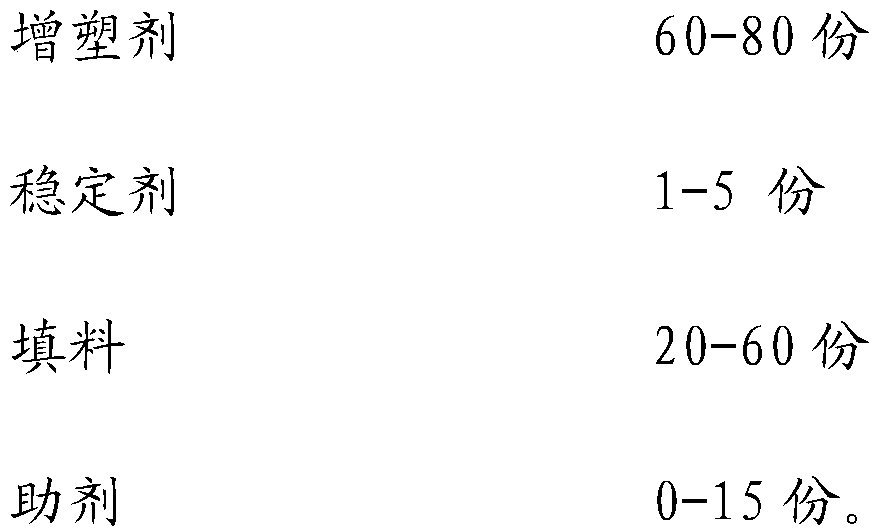

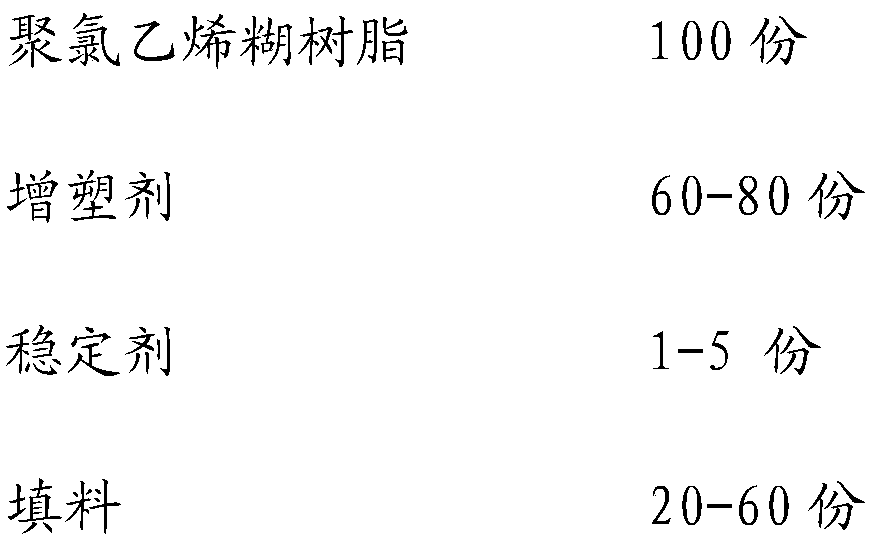

[0053] Wherein, the formula of PVC coating slurry is as follows:

[0054] The formula of the PVC coating slurry of table 1 embodiment 1

[0055]

[0056]

[0057] The formula of polyurethane surface treatment agent is as follows:

[0058] The formula of the polyurethane surface treatment agent of table 2 embodiment 1

[0059]

[0060] The preparatio...

Embodiment 2-5

[0065] Weigh the raw materials according to the proportions in Table 3-5 respectively, and prepare according to the steps in Example 1. The difference is that the added raw material proportions are different, and the products are prepared. For details, see the PVC coating in Table 3-4. Layer slurry and the formula consumption of polyurethane surface treatment agent in table 5.

[0066] Wherein, the formula of PVC coating slurry is as follows:

[0067] The formula of the PVC coating slurry of table 3 embodiment 2-3

[0068]

[0069] The formula of the PVC coating slurry of table 4 embodiment 4-5

[0070]

[0071]

[0072] The formula of polyurethane surface treatment agent is as follows:

[0073] The formula of the polyurethane surface treatment agent of table 5 embodiment 2-5

[0074]

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com