Composite thermal insulation coating and preparation method thereof

A heat-insulating coating and heat-insulating material technology, applied in the direction of reflection/signal coatings, coatings, etc., can solve the problems of troublesome preparation process, low quality stability, and high energy consumption in the production process, and achieve white appearance and low production cost. Low, not easy to fall off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Put 100 parts of hollow glass microspheres in an open container, and while stirring, spray 12 parts by mass of titanium dioxide sol on the surface of hollow glass microspheres in the form of a spray, gradually heat up to 80°C, and keep stirring until The hollow glass microspheres are no longer adhered, and then the hollow glass microspheres are placed in an airflow dryer at 110° C. for 30 minutes to obtain titanium dioxide-coated hollow glass microspheres.

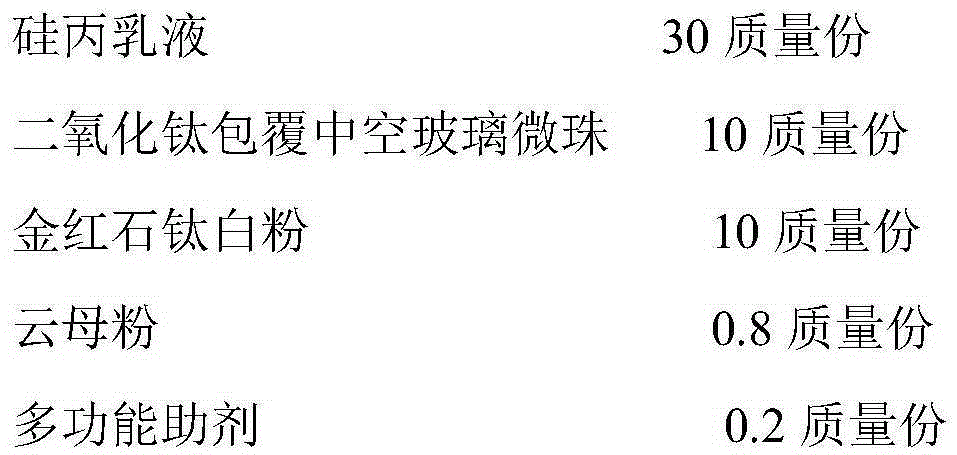

[0017] (2) The raw materials will be prepared according to the following formula

[0018]

[0019]

[0020] (3) Disperse titanium dioxide-coated hollow glass microspheres, rutile titanium dioxide, mica powder and additives at a high speed for 8 minutes at 1000rpm, stir evenly and put them into a grinder for grinding to obtain a slurry; reduce the rotational speed to 300rpm, add The silicone-acrylic emulsion was stirred for another 25 minutes at a speed of 300 rpm to obtain a composite heat-insulating coati...

Embodiment 2

[0023] (1) Put 100 parts of hollow glass microspheres in an open container, and while stirring, spray 12 parts by mass of titanium dioxide sol on the surface of hollow glass microspheres in the form of a spray, gradually heat up to 80°C, and keep stirring until The hollow glass microspheres are no longer adhered, and then the hollow glass microspheres are placed in an airflow dryer at 110° C. for 30 minutes to obtain titanium dioxide-coated hollow glass microspheres.

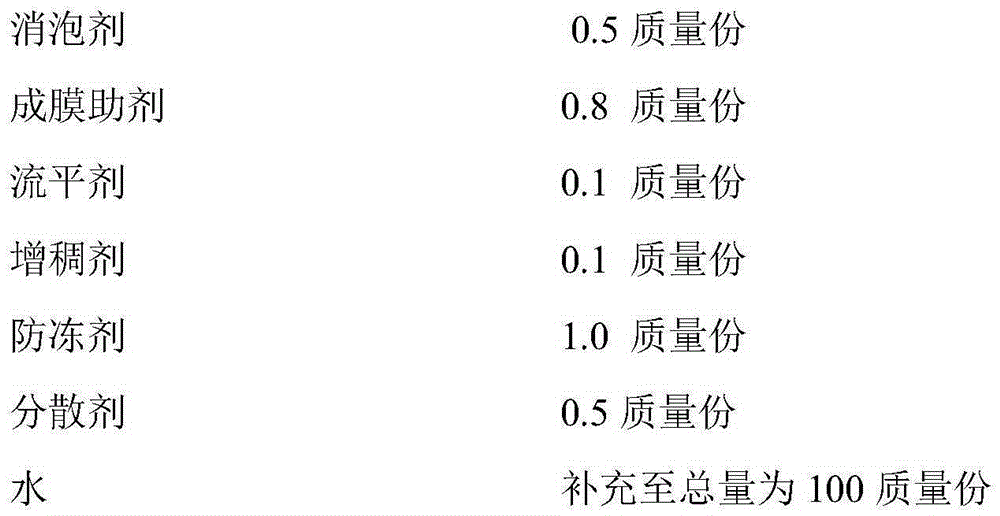

[0024] (2) The raw materials will be prepared according to the following formula

[0025]

[0026]

[0027] (3) Disperse titanium dioxide-coated hollow glass microspheres, rutile titanium dioxide, mica powder and additives at a high speed for 8 minutes at 1000rpm, stir evenly and put them into a grinder for grinding to obtain a slurry; reduce the rotation speed to 350rpm, add The silicon-acrylic emulsion was stirred for another 30 minutes at a speed of 350 rpm to obtain a composite heat-insulating coating....

Embodiment 3

[0030] (1) Put 100 parts of hollow glass microspheres in an open container, and while stirring, spray 12 parts by mass of titanium dioxide sol on the surface of hollow glass microspheres in the form of a spray, gradually heat up to 80°C, and keep stirring until The hollow glass microspheres are no longer adhered, and then the hollow glass microspheres are placed in an airflow dryer at 110° C. for 30 minutes to obtain titanium dioxide-coated hollow glass microspheres.

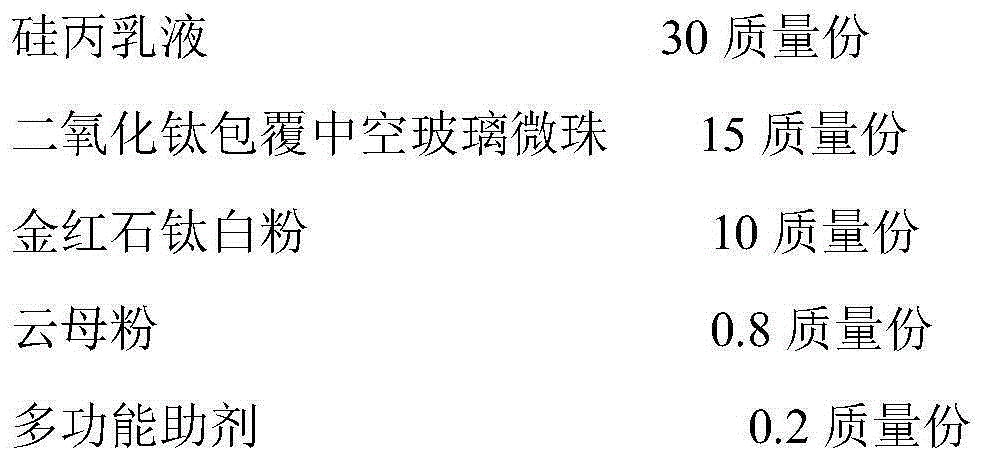

[0031] (2) The raw materials will be prepared according to the following formula

[0032]

[0033]

[0034](3) Disperse titanium dioxide-coated hollow glass microspheres, rutile titanium dioxide, mica powder and additives at high speed for 8 minutes at 1000rpm, stir evenly and put them into a grinder for grinding to obtain a slurry; reduce the rotational speed to 400rpm, add The silicone-acrylic emulsion was stirred for another 35 minutes at a speed of 400 rpm to obtain a composite heat-insulating coating....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com