Method for enhancing strength of 3D printed products

A 3D printing and product technology, applied in the field of 3D printing, can solve the problems of parts scrapping, cracking, breaking, etc., and achieve the effect of improving strength, expanding the scope of use, and increasing the strength of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 Using the method of the present invention to increase the strength of 3D printing products

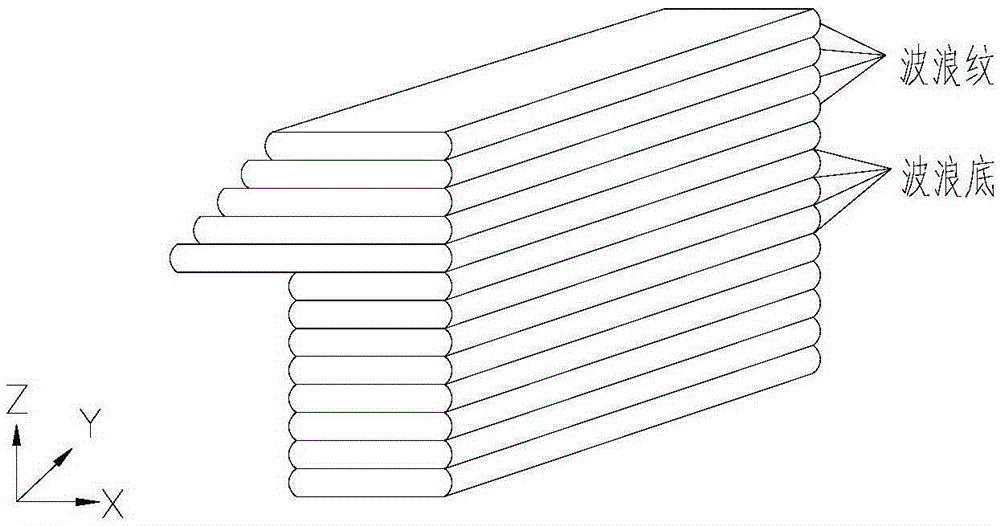

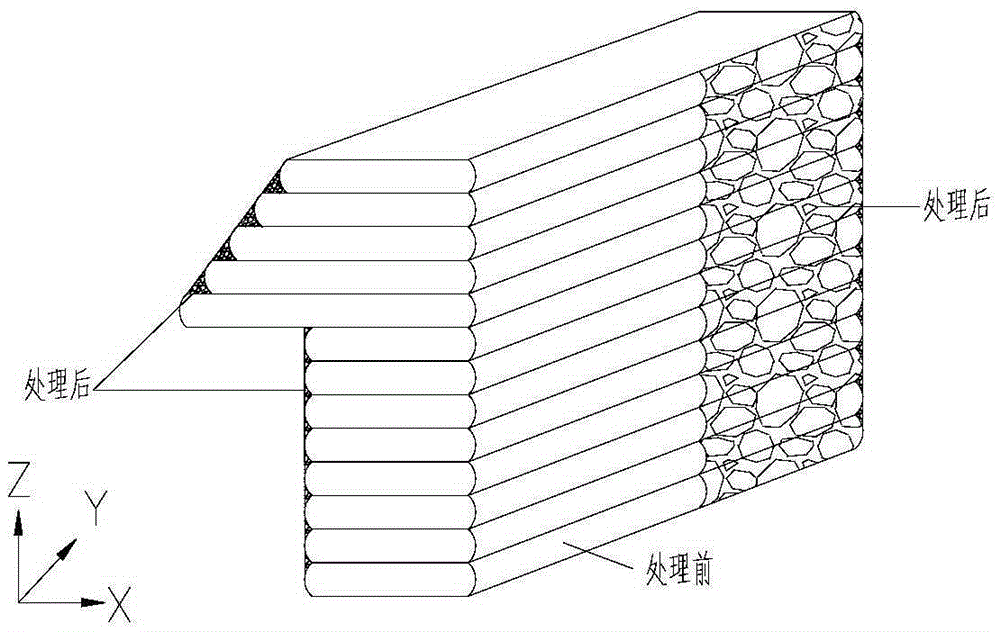

[0036] image 3 It is a schematic diagram of the shape and printing direction of a 3D printed hook part. exist image 3 It can be seen from the figure that the size of the Y and Z directions accumulated by the hook parts during 3D printing is much larger than the X direction, and the X direction size is 2mm, and the parts are easily broken due to the extrusion force in the X direction when the hook is assembled. .

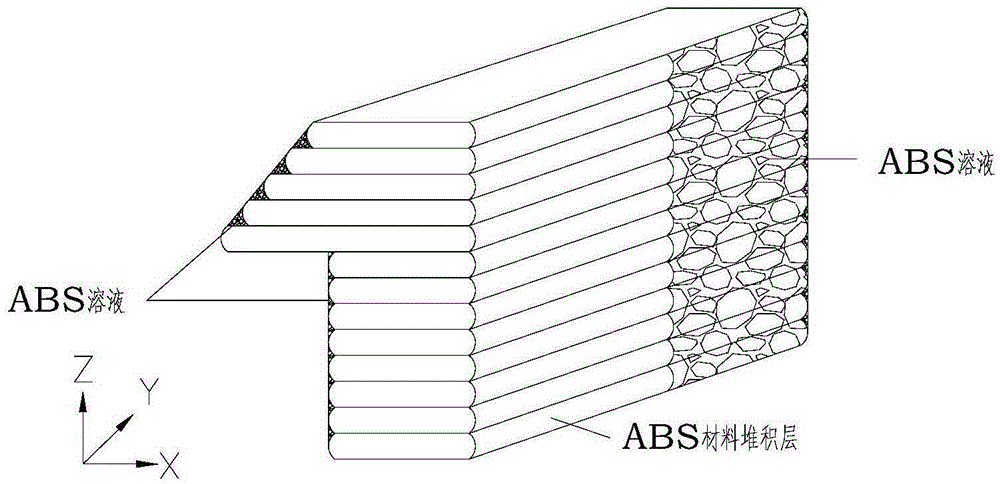

[0037] The raw material of the hook part is obtained by 3D printing of acrylonitrile-butadiene-styrene plastic (ABS). Take 50 parts of its powder by weight and dissolve it in 50 parts of ethyl acetate, stir to make it fully dissolve and stand still to obtain a solution. In the fume hood, use a metal sprayer to evenly spray the solution on the surface of the part parallel to the Y-Z plane. When the junction of the accumulation layer is filled, stop sp...

Embodiment 2

[0038] Embodiment 2 Using the method of the present invention to increase the strength of 3D printing products

[0039]The specification of the 3D printed part in this embodiment is the same as that of the 3D printed part in Embodiment 1, and it is obtained by printing with ABS material. Take 10 parts by weight of the raw material ABS powder for printing the part as a solute, take 50 parts by weight of ethyl acetate and 40 parts of acetone as a solvent, mix these three raw materials, stir them to fully dissolve and let stand. Use a brush to evenly coat the weak surface of the part in a ventilated place. When the junction of the accumulation layer is filled, stop brushing, wait for the solvent to evaporate completely, and then take out the reinforced 3D printed hook part.

Embodiment 3

[0040] Embodiment 3 Using the method of the present invention to increase the strength of 3D printing products

[0041] The specifications of the 3D printed parts in this embodiment are the same as those in the first embodiment, and they are printed with polycarbonate (PC) materials. Take 5 parts by weight of the raw material PC powder for printing the part as the solute, take 20 parts by weight of chloroform, 40 parts of methyl ethyl ketone, and 35 parts of tetrahydrofuran as the solvent, mix these four raw materials, stir them to fully dissolve and let stand to obtain a solution. In the fume hood, use a metal sprayer to evenly spray the solution on the weak surface of the part. When the junction of the accumulation layer is filled, stop spraying, wait for the solvent to evaporate completely, and then take out the enhanced 3D printed hook part.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com