Industrial inorganic sewage treatment system

A sewage treatment system and inorganic technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of removing heavy metal ions, single process, water pollution, etc., and achieve improvement Removal rate, environmental friendliness, effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

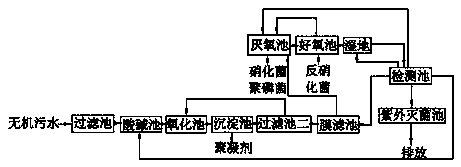

[0042] like figure 1 As shown, the industrial inorganic sewage treatment system includes an inorganic filter tank one, an acid-base tank, an oxidation tank, an inorganic sedimentation tank, an inorganic filter tank two and a membrane filter tank connected in sequence. The grid gap size of the inner grid of inorganic filter tank 1 is 5~8cm. The industrial inorganic sewage flows through the grid of inorganic filter tank 1, and after filtering out the particles larger than 5~8cm, the liquid flows to the acid-base tank. Use Ca(OH) in acid-base pools 2 The liquid is made into a saturated solution, and the saturated solution flows to the oxidation tank, where it undergoes the ferrite method, and is 2+ ) / n(M 2+ ) = 15 after removing heavy metal ions, the liquid flows to the inorganic sedimentation tank. When the sewage is in the inorganic sedimentation tank, add an inorganic coagulant with a concentration of 25ppm to the pool. The inorganic coagulant is composed of chitosan with a...

Embodiment 2

[0054] like figure 1 As shown, the industrial inorganic sewage treatment system includes an inorganic filter tank one, an acid-base tank, an oxidation tank, an inorganic sedimentation tank, an inorganic filter tank two and a membrane filter tank connected in sequence. The grid gap size of the inner grid of the inorganic filter tank 1 is 8cm. The industrial inorganic sewage flows through the grid of the inorganic filter tank 1. After filtering out the particles larger than 8cm, the liquid flows to the acid-base tank. Use Ca(OH) in acid-base pools 2 The liquid is made into a saturated solution, and the saturated solution flows to the oxidation tank, where it undergoes the ferrite method, and is 2+ ) / n(M 2+ ) = 15 after removing heavy metal ions, the liquid flows to the inorganic sedimentation tank. When the sewage is in the inorganic sedimentation tank, add an inorganic coagulant with a concentration of 25ppm to the pool. The inorganic coagulant is composed of chitosan with a...

Embodiment 3

[0066] like figure 1 As shown, the industrial inorganic sewage treatment system includes an inorganic filter tank one, an acid-base tank, an oxidation tank, an inorganic sedimentation tank, an inorganic filter tank two and a membrane filter tank connected in sequence. The grid gap size of the inner grid of the inorganic filter tank 1 is 7cm. The industrial inorganic sewage flows through the grid of the inorganic filter tank 1. After filtering out the particles larger than 7cm, the liquid flows to the acid-base tank. Use Ca(OH) in acid-base pools 2 The liquid is made into a saturated solution, and the saturated solution flows to the oxidation tank, where it undergoes the ferrite method, and is 2+ ) / n(M 2+ ) = 15 after removing heavy metal ions, the liquid flows to the inorganic sedimentation tank. When the sewage is in the inorganic sedimentation tank, add an inorganic coagulant with a concentration of 25ppm to the pool. The inorganic coagulant is composed of chitosan with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com