Non-woven fabric napkin arrangement and output device and transportation method

A technology of output device and cloth trousers, which is applied in the direction of packaging, etc., can solve the problems such as the device can only stop, control more, and the frequency of failure is high, so as to achieve the effect of reasonable layout, improved production efficiency and reduced waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

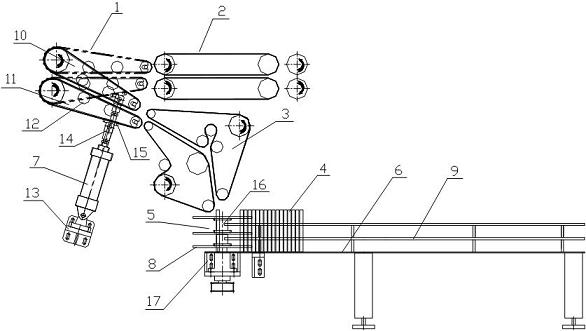

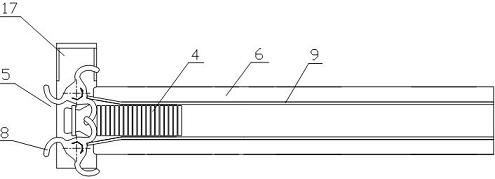

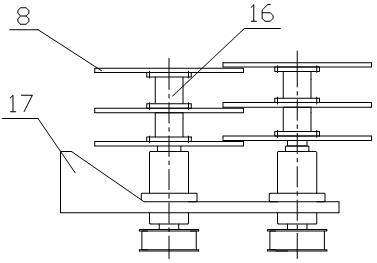

[0011] Example 1: Refer to the attached Figure 1-3 . The non-woven pants arrangement output device includes an upper conveying mechanism 2. The left side of the upper conveying mechanism 2 is the swing arm conveying mechanism 1, the lower conveying mechanism 3 under the upper conveying mechanism 2 and the lower conveying mechanism 3 are wheels Fork mechanism 5, the right side of fork mechanism 5 is the product output platform 6. The product output platform 6 is equipped with a guardrail 9. The guardrail 9 is composed of two horizontal rods and several vertical rods. The height of the guardrail 9 is lower than the height of the product 4. The part of the guardrail 9 close to the fork mechanism 5 is a bell mouth. The length and width of the product output platform 6 and guardrail 9 are determined by the actual situation. The bell mouth can make the falling product 4 smoothly pushed into the product output platform 6, guardrail 9 The position of the product 4 on the product outp...

Embodiment 2

[0022] Example 2: On the basis of Example 1, the non-woven pants arrangement output method, the cylinder 7 is raised, the swing arm conveying mechanism 1 is flush with the upper conveying mechanism 2, and the non-woven product is fed from the swing arm conveying mechanism 1 , Through the upper conveying mechanism 2 to enter the subsequent automatic stacking and packaging mechanism; the cylinder 7 is lowered, the swing arm conveying mechanism 1 is aligned with the lower conveying mechanism 3, and the non-woven product is sent from the swing arm conveying mechanism 1 to the lower conveying mechanism 3 Go down into the wheel fork mechanism 5, rotate the wheel fork 8, and use the special shape structure of the wheel fork 8 to push the non-woven product onto the product output platform 6, and pass the guardrails 9 on both sides of the product output platform 6 neatly The arrangement output.

[0023] That is to say, when the stacking and packaging process fails, the air cylinder 7 auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com