Biological-polysaccharide-based decoloring flocculation agent and preparation method thereof

A technology of decolorizing flocculant and biological polysaccharide, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc. It can solve the problems that the molecular weight and structural properties are difficult to meet the actual needs, and achieve good social and economic benefits, no secondary pollution, and a wide market foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

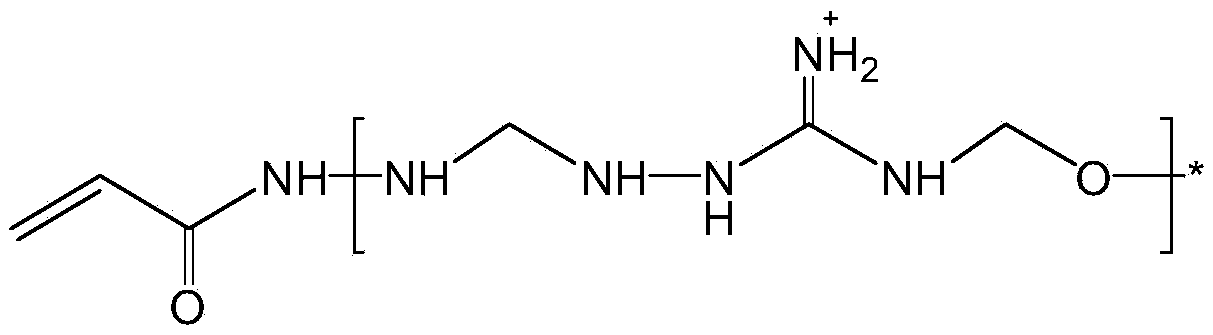

[0030] Preparation of dicyandiamide-formaldehyde condensation polymer solution containing carbon-carbon double bonds at the end: In a four-necked flask equipped with an electric stirrer, a thermometer, and a reflux condenser, add 63g of dicyandiamide, 11.25g of urea, and 53.25g of acrylamide in sequence , 40.13g of ammonium chloride, 81.08g of 37% formaldehyde solution, the temperature of the water bath is controlled at 35-45°C, and the stirring is started. After it is completely dissolved, 11.25g of ethylenediamine is added. When it drops to 48°C, slowly add 40.54g of 37% formaldehyde solution dropwise, then raise the temperature to 66-68°C, keep it warm for 2 hours, take it out, and cool it down to obtain the product.

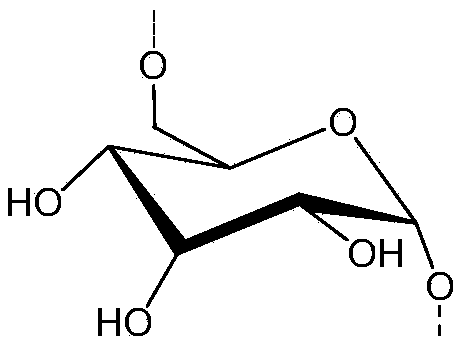

[0031] Dilute the above product into a 50% aqueous solution, take 50g of the solution and add it to a 500ml three-necked flask, then add 170g of a biological polysaccharide solution with a mass concentration of 15%, start stirring, and slowly heat up to 45°C, ...

Embodiment 2

[0033] Preparation of dicyandiamide-formaldehyde polycondensate solution containing carbon-carbon double bonds at the end: In a four-necked flask equipped with an electric stirrer, a thermometer, and a reflux condenser, add 69g of dicyandiamide, 12.33g of urea, and 58.32g of acrylamide in sequence , 26.39g of ammonium chloride, 100g of 37% formaldehyde solution, the temperature of the water bath is controlled at 45-50°C, and the stirring is started. After it is completely dissolved, 12.33g of ethylenediamine is added. When it reaches 50°C, slowly add 66.67g of 37% formaldehyde solution dropwise, then raise the temperature to 66-68°C, keep it warm for 2h, take it out, and cool it down to obtain the product.

[0034] Dilute the above product into a 50% aqueous solution, take 60g of the solution and add it to a 500ml three-necked flask, then add 100g of a biological polysaccharide solution with a mass concentration of 15%, start stirring, and slowly heat up to 50°C, and after pass...

Embodiment 3

[0036]Preparation of dicyandiamide-formaldehyde polycondensate solution containing carbon-carbon double bonds at the end: In a four-necked flask equipped with an electric stirrer, a thermometer, and a reflux condenser, add 123.34g of dicyandiamide, 15.42g of urea, and 104.3g of propylene in sequence Amide, 1.47mol of HCl, 100g of 37% formaldehyde solution, the temperature of the water bath is controlled at 35-45°C, and stirring is started. After it is completely dissolved, 15.42g of ethylenediamine is added. When it reaches 48°C, slowly add 66.67g of 37% formaldehyde solution dropwise, then raise the temperature to 66-68°C, keep it warm for 2 hours, take it out, and cool it down to obtain the product.

[0037] Dilute the above product into a 50% aqueous solution, take 20g of the solution and add it to a 500ml three-necked flask, then add 125g of a biological polysaccharide solution with a mass concentration of 8%, start stirring, and slowly heat up to 45°C, and after passing ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com