An acceleration sensor device based on symmetric graphene nanoribbons

A graphene nanoribbon, acceleration sensing technology, applied in the field of sensors, can solve the problems of low sensitivity and long response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

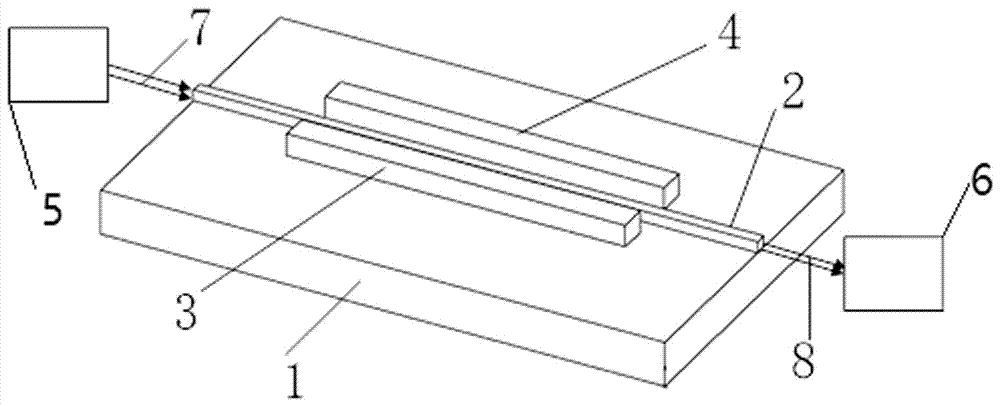

[0017] refer to figure 1 , a kind of acceleration sensing device of symmetric graphene nanoribbon, comprises the base layer 1 of bottom layer, is provided with the first strip graphene nanoribbon 3 and the second strip graphite of same size symmetrical arrangement on the surface layer of base layer 1 Graphene nanobelt 4, the first strip-shaped graphene nanobelt 3, and the second strip-shaped graphene nanobelt 4 are provided with a micro-nano optical fiber straight waveguide 2.

[0018] The base layer 1 is an SOI base layer.

[0019] The first strip-shaped graphene nanoribbon 3 and the second strip-shaped graphene nanoribbon 4 form a symmetrical surface plasmon waveguide structure of graphene-dielectric-graphene, so that the output signal resonance waveguide and device sensitivity can be controlled by controlling the properties of the fiber medium .

[0020] A buried oxide layer is introduced between the top silicon layer of SOI and the back substrate in the base layer 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com