Two-roller cold rolling mill structure for copper rod

A technology of cold rolling mills and copper rods, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of copper rods that are prone to flashing, brittle skin, etc., and achieve the effect of ensuring surface quality and rolling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

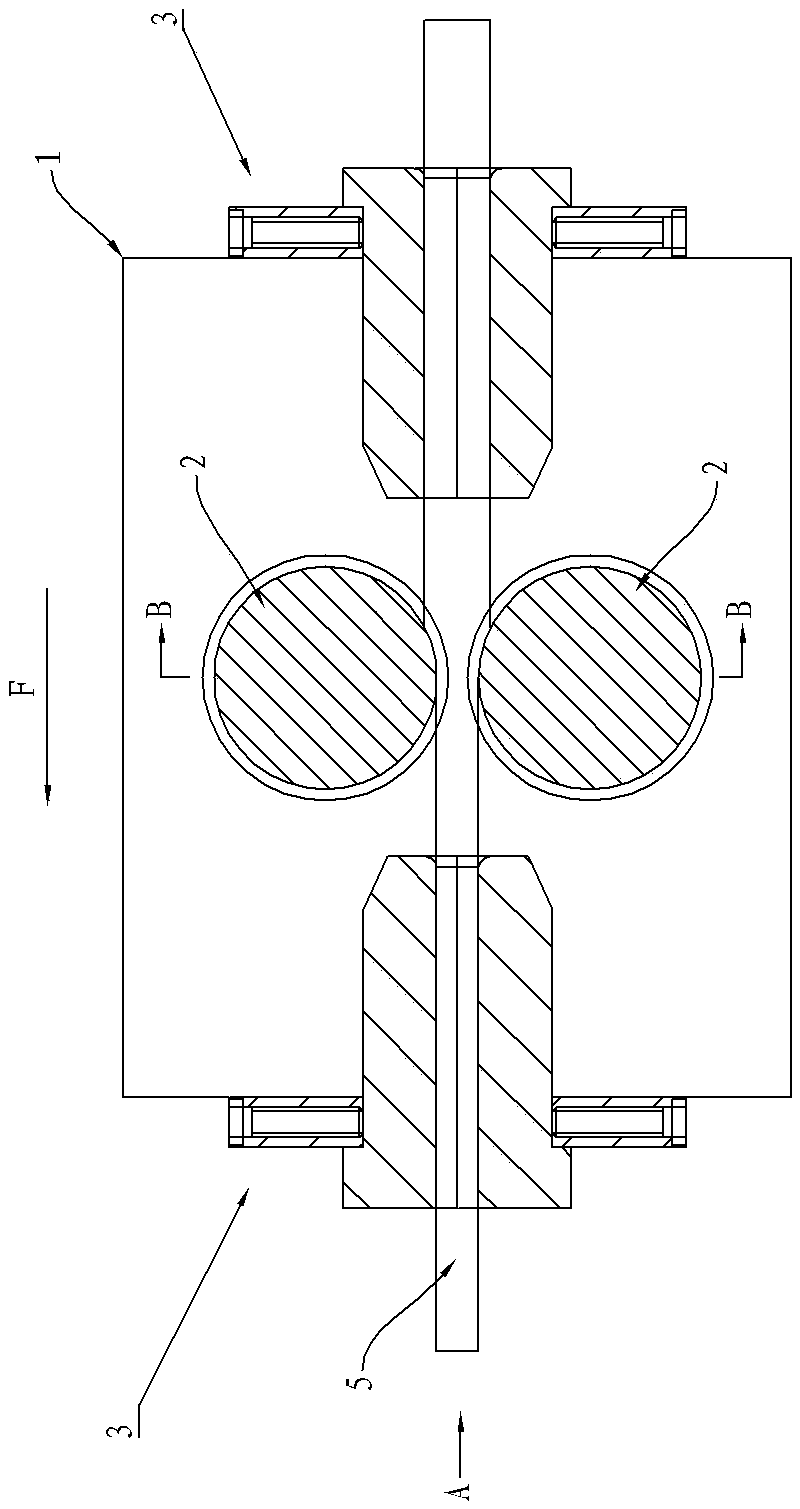

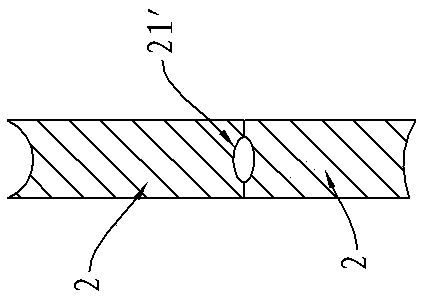

[0022] The structure of the two-roll copper rod cold rolling mill of the present invention includes a stand 1, a pair of roll devices and a guide device 3. The two rolls 2 of the pair of roll devices are horizontally rolled according to the requirements of horizontal or vertical rolling in actual production. They are installed in the frame 1 symmetrically or vertically. This embodiment is a vertical rolling form, so the two rolls 2 are installed in the frame 1 symmetrically vertically, see Figure 4 , The positioning device 3 is provided with two sets, the two sets of positioning devices 3 are symmetrically installed at the entrance and exit of the copper rod of the frame 1. The positioning device 3 includes a positioning sleeve 31 and two positioning blocks 32a, 32b, The two guide blocks 32a, 32b are installed mirror-symmetrically to each other at the entrance or exit end of the copper rod of the frame 1 through the guide sleeve 31. The installation direction of the two guide bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com