Steering mechanism of glue sprayer for polyurethane rollers

A technology of steering mechanism and glue spraying machine, applied in the direction of spraying device, etc., can solve the problems of temperature, flow influence, influence on the coating effect of glue spray gun, etc., and achieve good coating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

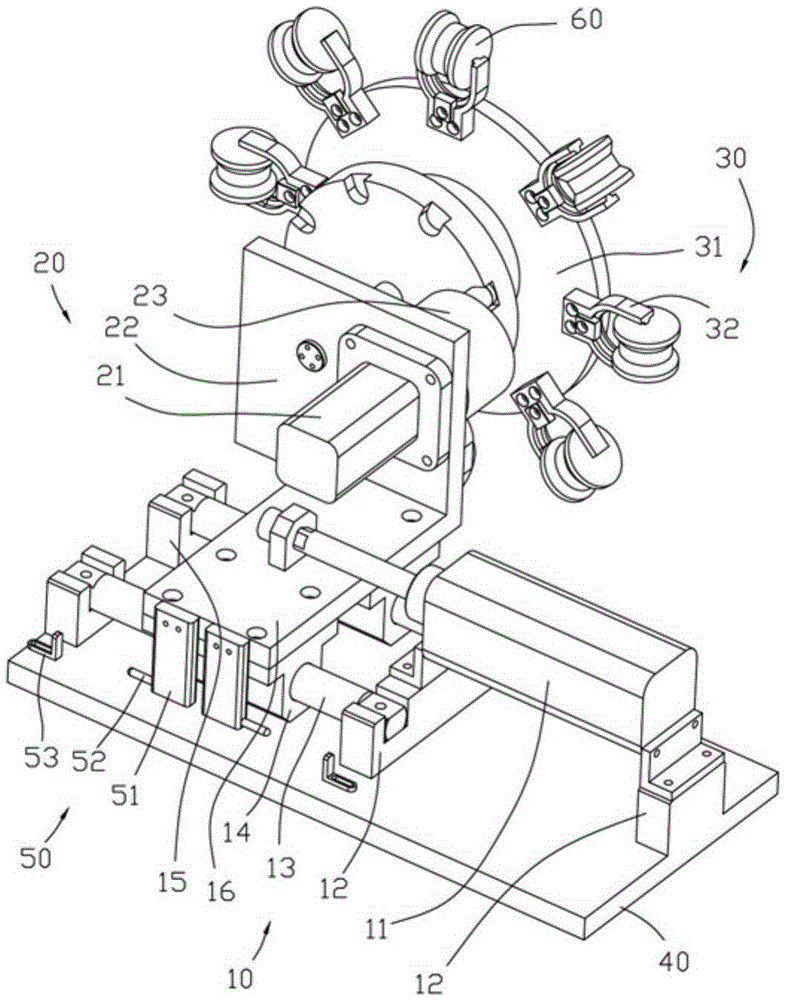

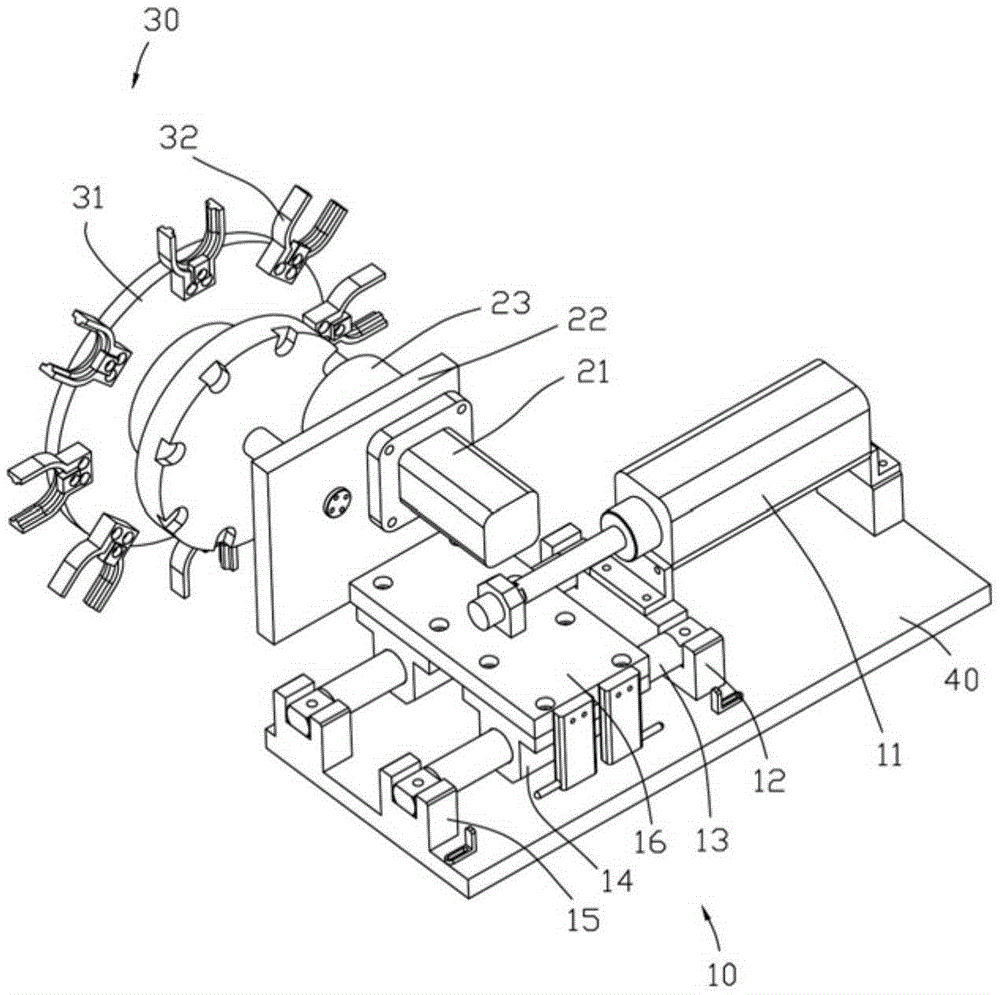

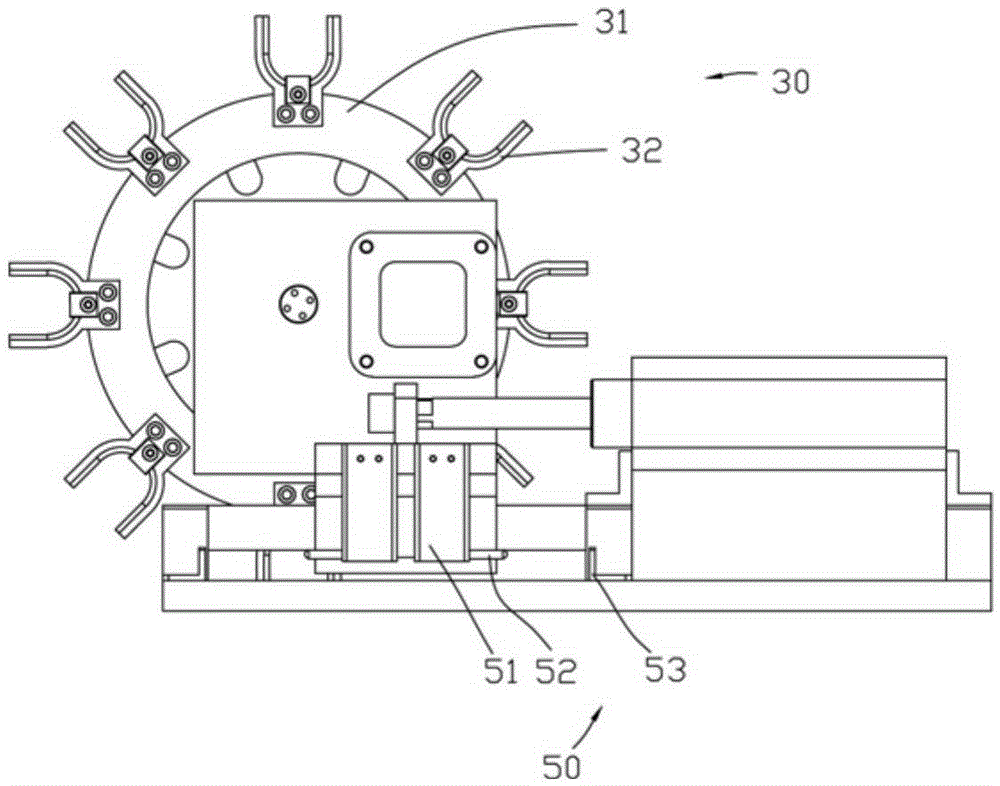

[0018] combine Figure 1 to Figure 7 , a steering mechanism of a polyurethane roller glue spraying machine, including a base plate 40, on which a cylinder transmission assembly 10 is installed, and the cylinder transmission assembly 10 includes a cylinder 11 and a sliding plate 16, and the moving rod of the cylinder 11 and the sliding plate 16 Fixed connection; one side of the sliding plate 16 is provided with two sets of limit assemblies 50, and the other side is provided with a motor transmission assembly 20, the sliding plate 16 is connected with the motor seat 22 of the motor transmission assembly 20, and the motor The seat 22 is vertically arranged, and the rotating disk 31 of the roller frame assembly 30 is installed on the motor seat 22, and the rotating disk 31 is provided with a roller frame 32.

[0019] combine figure 1 and figure 2 , the motor transmission assembly 20 also includes a motor 21 and a drive disc 23, the motor 21 is installed on the motor base 22, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com