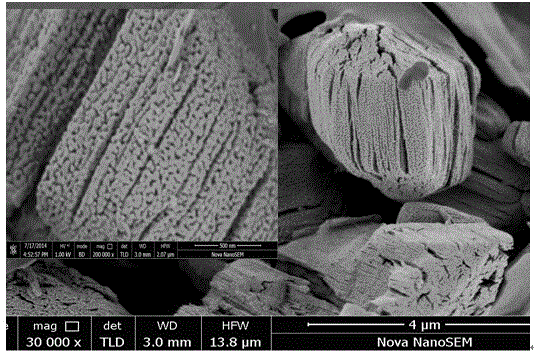

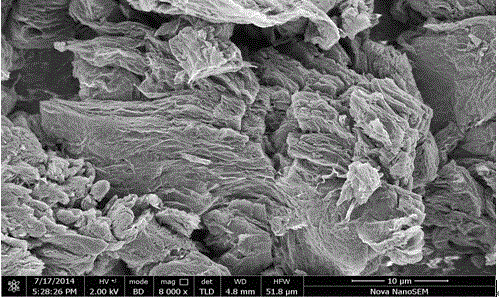

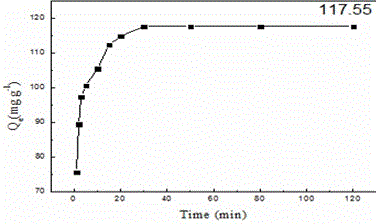

Preparation method of graphene/ferrate multi-stage three-dimensional structure dye adsorbent

A three-dimensional structure, ferrite technology, used in chemical instruments and methods, other chemical processes, etc., can solve problems such as pollution, and achieve the effects of stable chemical properties, high specific surface area, and good dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0012] Example 1: Weigh 0.01 of graphene oxide powder into a beaker, add 15ml of distilled water, and ultrasonically disperse evenly. Dissolve and mix zinc sulfate, ferrous sulfate, and oxalic acid in distilled water at a ratio of 1:2:1, and add them into the graphene dispersion liquid for ultrasonic dispersion. The uniform mixed solution was transferred to a polytetrafluoroethylene hydrothermal kettle, placed in a 100-degree oven, and the reaction time was 12 hours. After the reaction was completed, the hydrothermal kettle was taken out, the product was filtered and washed, and the dried powder sample was calcined in a 200-degree muffle furnace for 3 hours at a temperature of 300 degrees. The calcined product was taken out and used for the adsorption test of Congo red dye.

example 2

[0013] Example 2: Weigh 0.05g of graphene oxide powder into a beaker, add 5ml of distilled water, and ultrasonically disperse evenly. Use methanol to dissolve and mix zinc sulfate, ferrous sulfate, and oxalic acid in a substance ratio of 1:2:5, and add them to the graphene dispersion liquid for ultrasonic dispersion. The uniform mixed solution was transferred to a polytetrafluoroethylene hydrothermal kettle, placed in an oven at 150 degrees, and the reaction time was 16 hours. After the reaction was completed, the hydrothermal kettle was taken out, the product was filtered and washed, and the dried powder sample was calcined in a 400-degree muffle furnace for 5 hours at a temperature of 500 degrees. The calcined product was taken out and used for the adsorption test of Congo red dye.

example 3

[0014] Example 3: Weigh 0.1 g of graphene oxide powder into a beaker, add 10 ml of distilled water, and ultrasonically disperse evenly. Dissolve and mix zinc sulfate, ferrous sulfate, and oxalic acid with ethanol at a ratio of 1:2:3, and add them into the graphene dispersion liquid to disperse evenly by ultrasonic. The uniform mixed solution was transferred to a polytetrafluoroethylene hydrothermal kettle, placed in a 200-degree oven, and the reaction time was 6 hours. After the reaction was completed, the hydrothermal kettle was taken out, the product was filtered and washed, and the dried powder sample was calcined in a 400-degree muffle furnace for 6 hours at a temperature of 400 degrees. The calcined product was taken out and used for the adsorption test of Congo red dye.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com