Automatic cleaning heat-insulation hog house

An automatic cleaning and pig house technology, which is applied in the field of pig breeding, can solve the problems of increasing the risk of pig infection, the toxicity of disinfectants, labor costs, etc., and achieve the effect of highlighting substantive features, convenient and automatic elimination, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

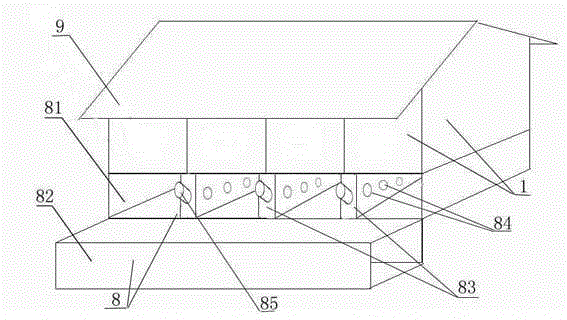

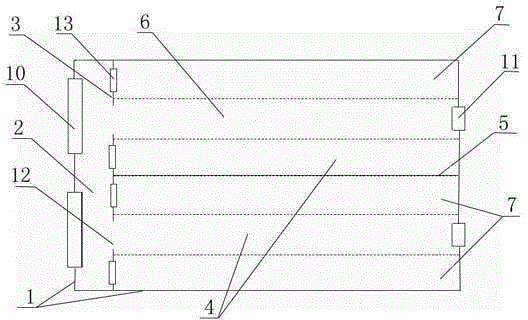

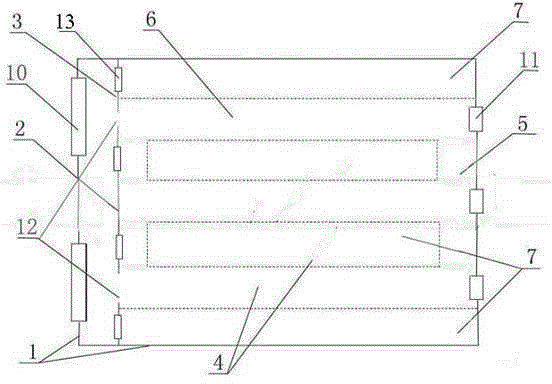

[0051] Such as figure 1 , figure 2 , image 3 and Figure 7 As shown, the self-cleaning heat preservation pig house includes an outer wall 1, an outer walkway 2, an outer walkway partition wall 3, a pigsty area 4, a pen area partition wall 5, an inner walkway 6, a slatted plate 7, and a defecation structure 8 and pig house roof 9; in the longitudinal direction in the pig house, a water curtain 10 is provided on the outer wall of one side, and a fan 11 is provided on the outer wall of the opposite side; the pig house is provided with a water curtain 10 The side is provided with a horizontal outer aisle 2, and the outer aisle partition wall 3 separates the outer aisle 2 from the pigsty area 4, and the outer aisle partition wall 3 is provided with a fence area door 12 in the middle, and both sides are provided with air inlet windows 13; The pigsty area 4 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com