Preparation method and application for delta-MnO2 thick film pseudocapacitor electrode

A pseudocapacitor and electrode technology, which is applied in the field of preparation of δ-MnO2 thick film pseudocapacitor electrodes, can solve the problems of low active material loading and cycle life, complex manganese oxide crystal phase, complex synthesis process, etc., and achieve shortening Ion diffusion radius, excellent electrochemical properties, and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

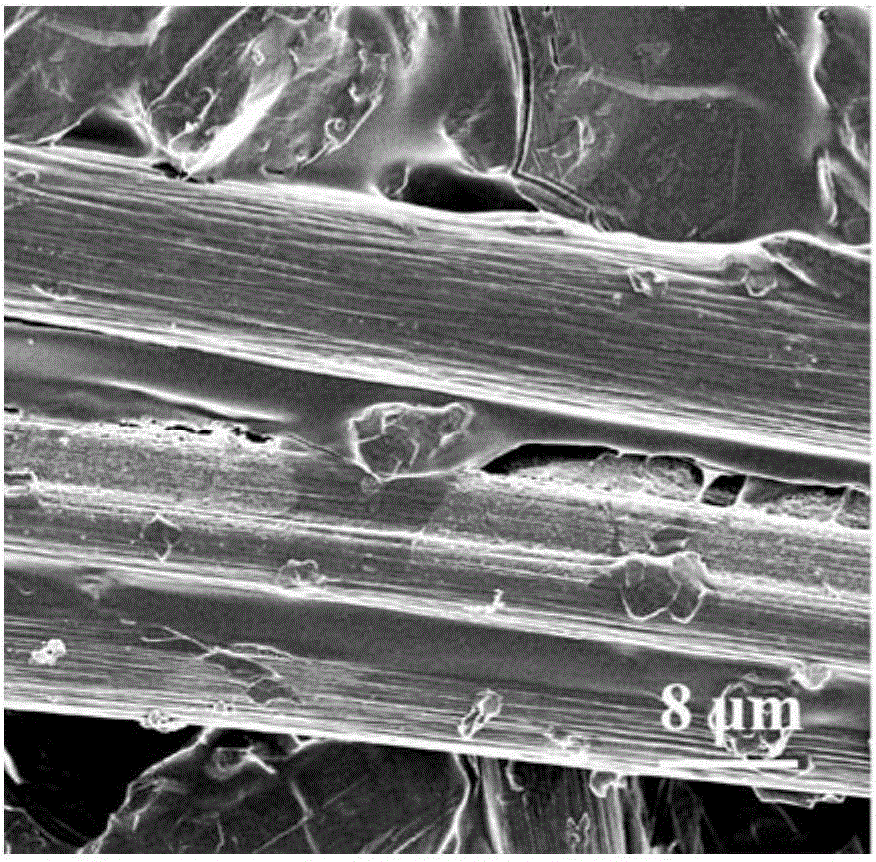

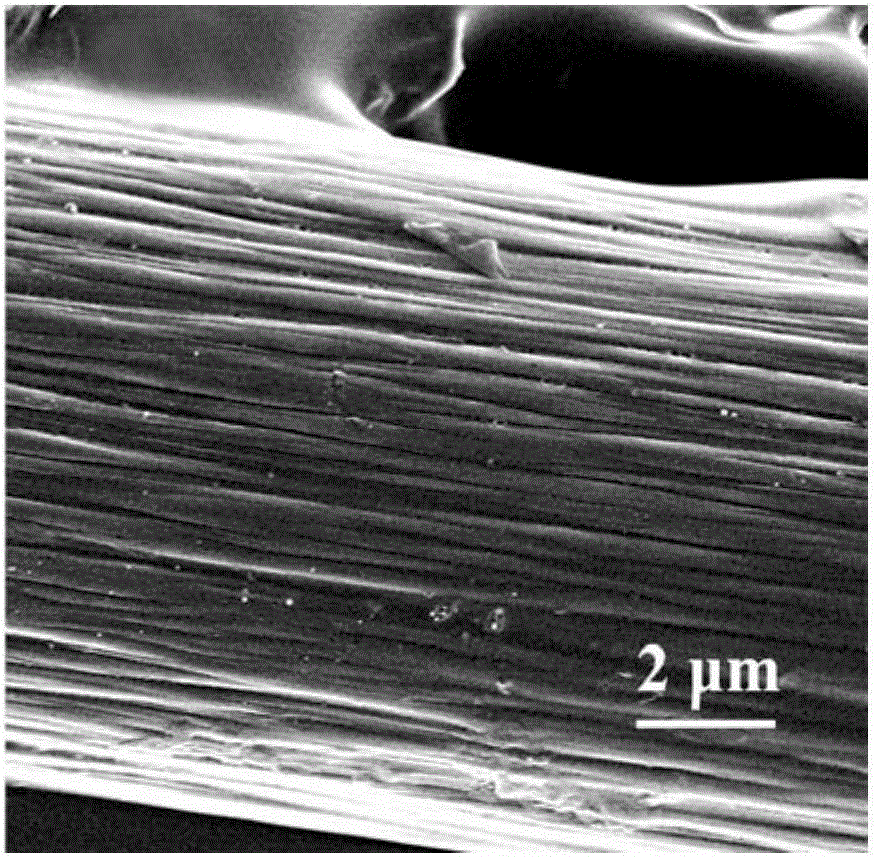

[0055] (1) Immerse 10x5 cm carbon fiber paper in potassium permanganate solution (0.5M), soak for 0.5h, take it out and dry it at room temperature, then wash it with pure water, and finally dry it at 70°C. The treated carbon fiber paper ( CFP) morphology was characterized by electron microscopy (SEM), as Figure 1a and Figure 1b .

[0056] (2) Electrochemical deposition of MnO 2 . Deposition step: Use 100 mL of precursor solution containing 0.1M Na 2 SO 4 and 0.1MMn(AC) 2 , the solvent is water, the treated carbon paper is used as a working electrode, Ag / AgCl is used as a reference electrode, and the Pt mesh is used as a counter electrode; first, it is kept at 0.4V for 20s, and then deposited at 0.45V for 1min. After the deposition step is completed, the The resulting working electrode was fully washed with deionized water, and finally dried at a constant temperature of 140 °C for 4 h to obtain δ-MnO 2 Thick-film pseudocapacitor electrodes, labeled as CFPMnO 2 -1min sa...

Embodiment 2

[0060] (1) The processing process of the substrate in this embodiment is the same as the step (1) of Embodiment 1, and will not be repeated here.

[0061] (2) Hydrothermal growth of Ga-ZnO array: configure 73mL of precursor solution, first configure 71mL of aqueous solution, which contains 0.015M Zn(NO 3 ) 2 , 0.015M cyclohexamethylenetetramine, and Ga 3+ / Zn 2+ Ga(NO) with a molar ratio of 0.5% 3 ) 3 , after fully stirring, 2 mL of NH 3 h 2 O, form a precursor solution (73mL), continue to stir, and finally soak the pretreated commercial carbon fiber paper in the precursor solution and transfer it to a reaction kettle with a Teflon liner, and keep the temperature at 90°C for 24h to obtain Conductive substrate with high specific surface area. Through the scanning electron microscope, it can be seen that the ZnO nanowires grow vertically along the surface of the carbon fiber, uniformly cover the carbon surface, and are distributed in the shape of a sea urchin, with a diam...

Embodiment 3

[0067] The substrate treatment method, hydrothermal growth Ga-ZnO array, MnO 2 The electrochemical deposition method and electrochemical performance test are the same as steps (1), (2), (3) and (4) in Example 2, and will not be repeated here. Increase the deposition time from 1 min to 5 min. The amount of deposition increased to 0.41mg / cm 2 , MnO 2 The nanoparticles gradually grow into nanowires and form a porous film, and the GZO substrate is partially corroded, such as Figure 14a , Figure 14b , Figure 14c and Figure 14d .

[0068] With the CFPGZOMnO prepared in this embodiment 2 -5min as a supercapacitor electrode, at a scan rate of 2mV / s, the specific capacitance is 613F / g, and the area specific capacitance is 0.25F / cm 2 . Change the cycle scanning speed to test the specific capacitance of the electrode, and the results obtained are shown in Figure 15a and Figure 15b , when the scan rate increased from 2 to 200mV / s, the specific capacitance decreased from 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com