Four-head longitudinal wrapping die

A technology of longitudinal molding and mould, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc. It can solve the problems of easy breakage of aluminum foil, large friction coefficient, and poor wear resistance of plastic molds, so as to achieve uniform capacitance and reduce friction coefficient , Improve the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

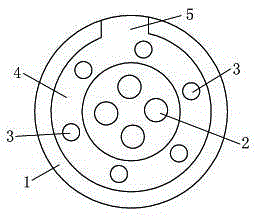

[0012] Combine below figure 1 Specific description embodiment:

[0013] Such as figure 1 As shown, the four-head longitudinal wrapping mold, the four-head longitudinal wrapping mold includes a mold body 1, and the mold body 1 is provided with a number of wire-to-wrapped aluminum foil channels 2, and the mold body 1 is located on the wire-to-wrapped A plurality of air outlets 3 are provided around the aluminum foil channel 2, and an annular hollow belt 4 is provided inside the mold body 1, and the air outlet 3 communicates with the annular hollow belt 4, and the side of the mold body 1 There is an air inlet 5 at the top, the air inlet 5 communicates with the annular hollow belt 4, and the air inlet 5, the annular hollow belt 4, and the air outlet 3 form a blowing heat dissipation device.

[0014] Preferably, the mold body is a columnar body made of tungsten steel through high polishing.

[0015] The preferred method is that there are 4 wire-to-wrapped aluminum foil channels,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com