Color sorting method

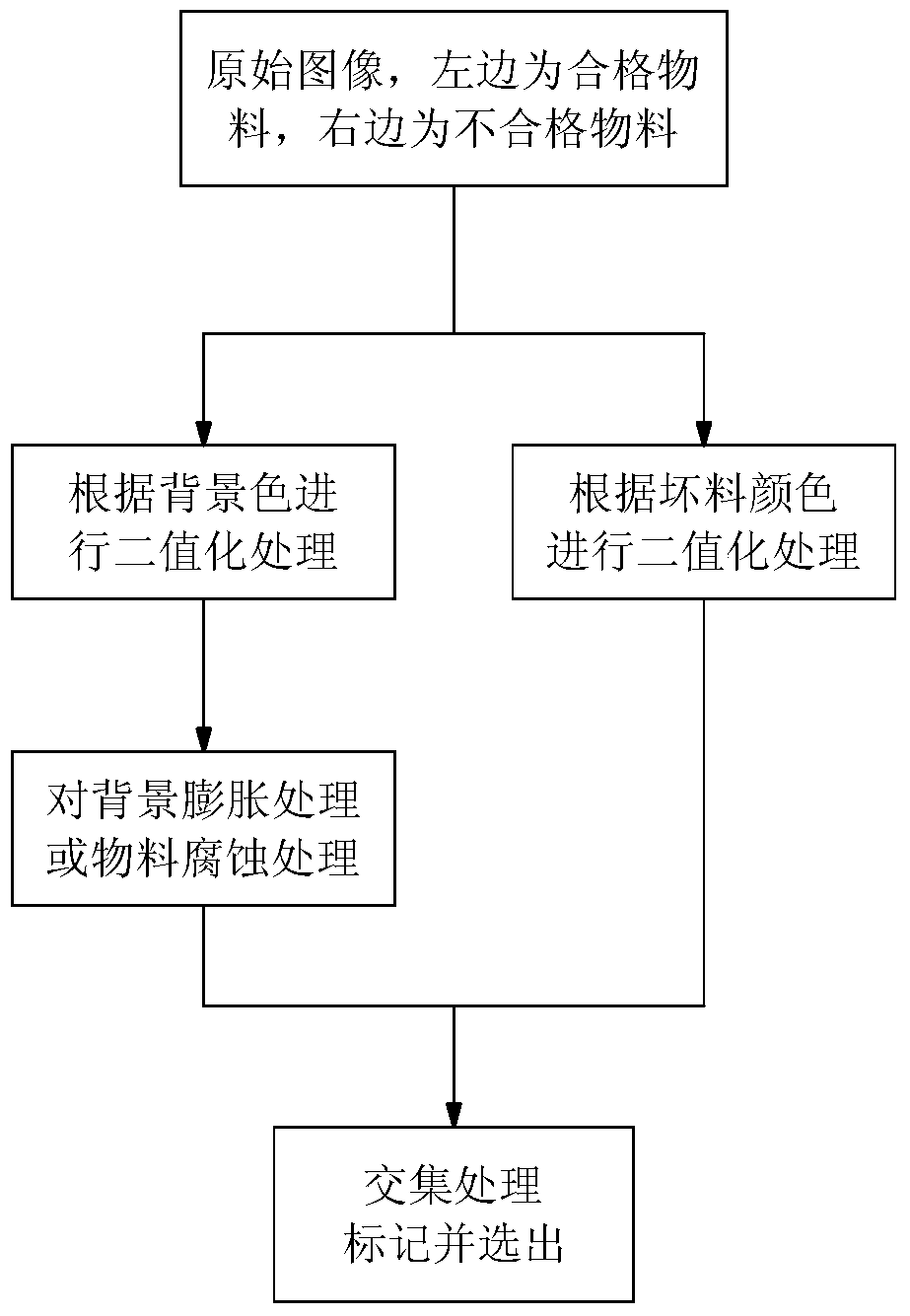

A color sorting and background color technology, applied in the field of color sorting, can solve the problems of misjudgment by color sorter, misselecting good materials, uneven surface, etc., to avoid misjudgment and improve color sorting accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0014] Embodiment 2, in the first black-and-white image, the background area is marked as 1, and the material area is marked as 0; in the second black-and-white image, the bad material area and shadow area are marked as 0, and the remaining areas are marked as 1; in step D , to expand the area marked as 1; in step E, the intersection processing is to perform logical OR operation on the two marks at the same position of the two images, and the area marked as 0 after the operation is the area containing bad materials. Embodiment 2 is similar to Embodiment 1, except that in the process of binarization, the area color marks are opposite. It should be noted that when processing in this way, it is no longer a logical AND operation but a logical OR operation in the intersection processing , and the area marked as 0 after the operation is the area containing bad material.

[0015] As a preferred solution of the present invention, in the step A, the original image is converted from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com