Color sorter feeding device and color sorter

A feeding device and color sorter technology, applied in the field of color sorters, can solve the problems of reducing the production efficiency of color sorters, destroying color sorting materials, poor versatility, etc. The effect of outward impact and improved color sorting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

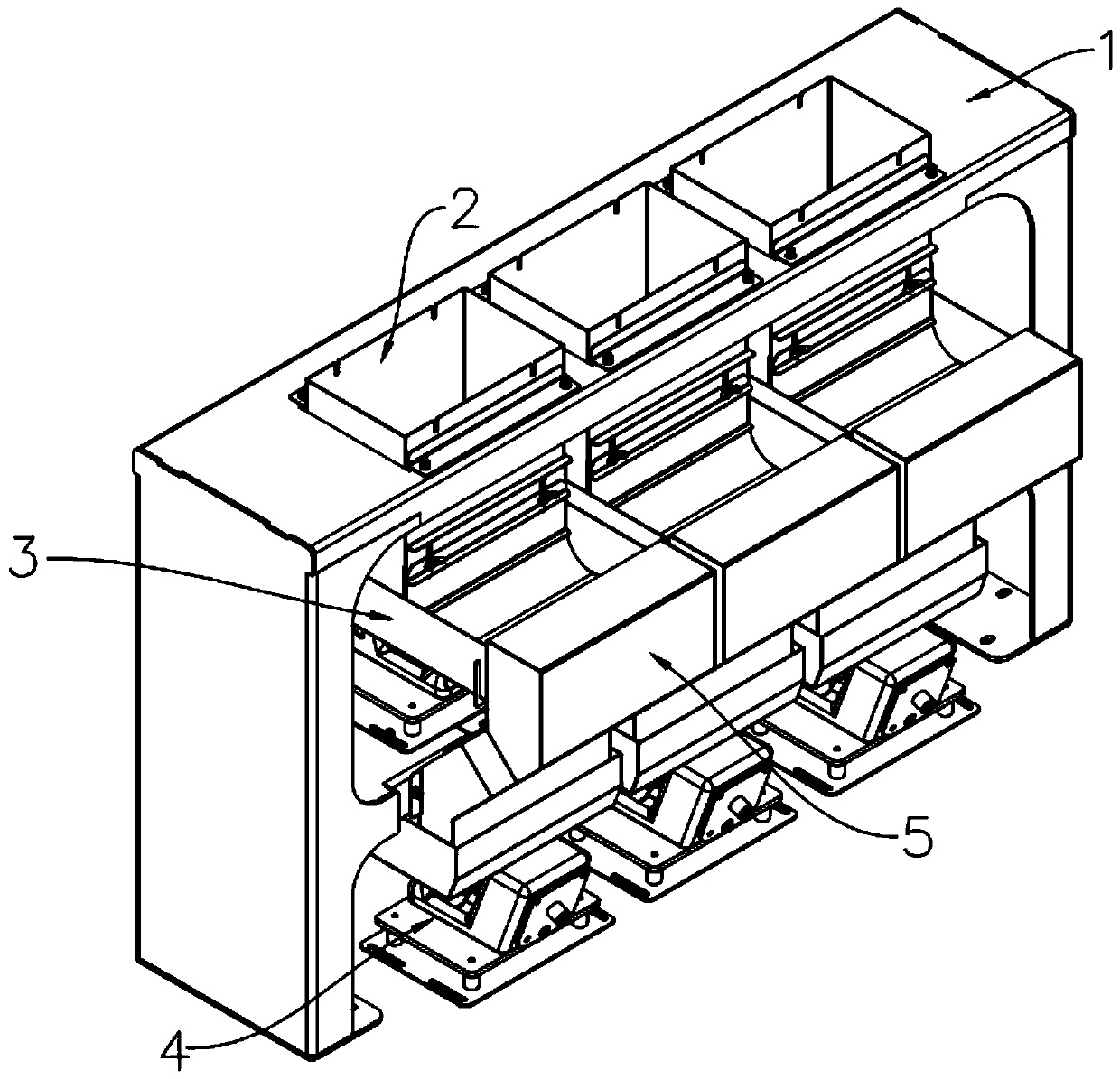

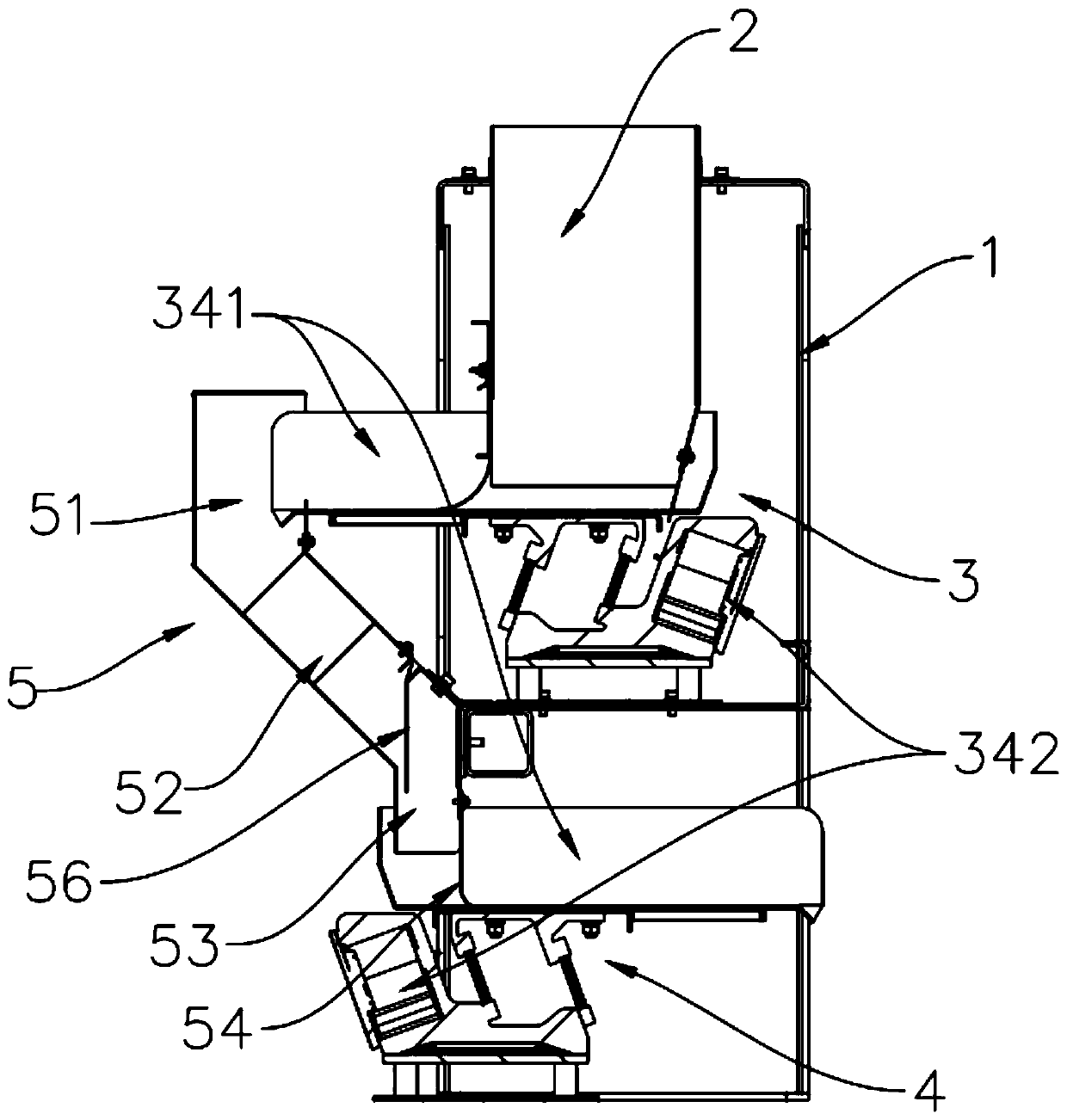

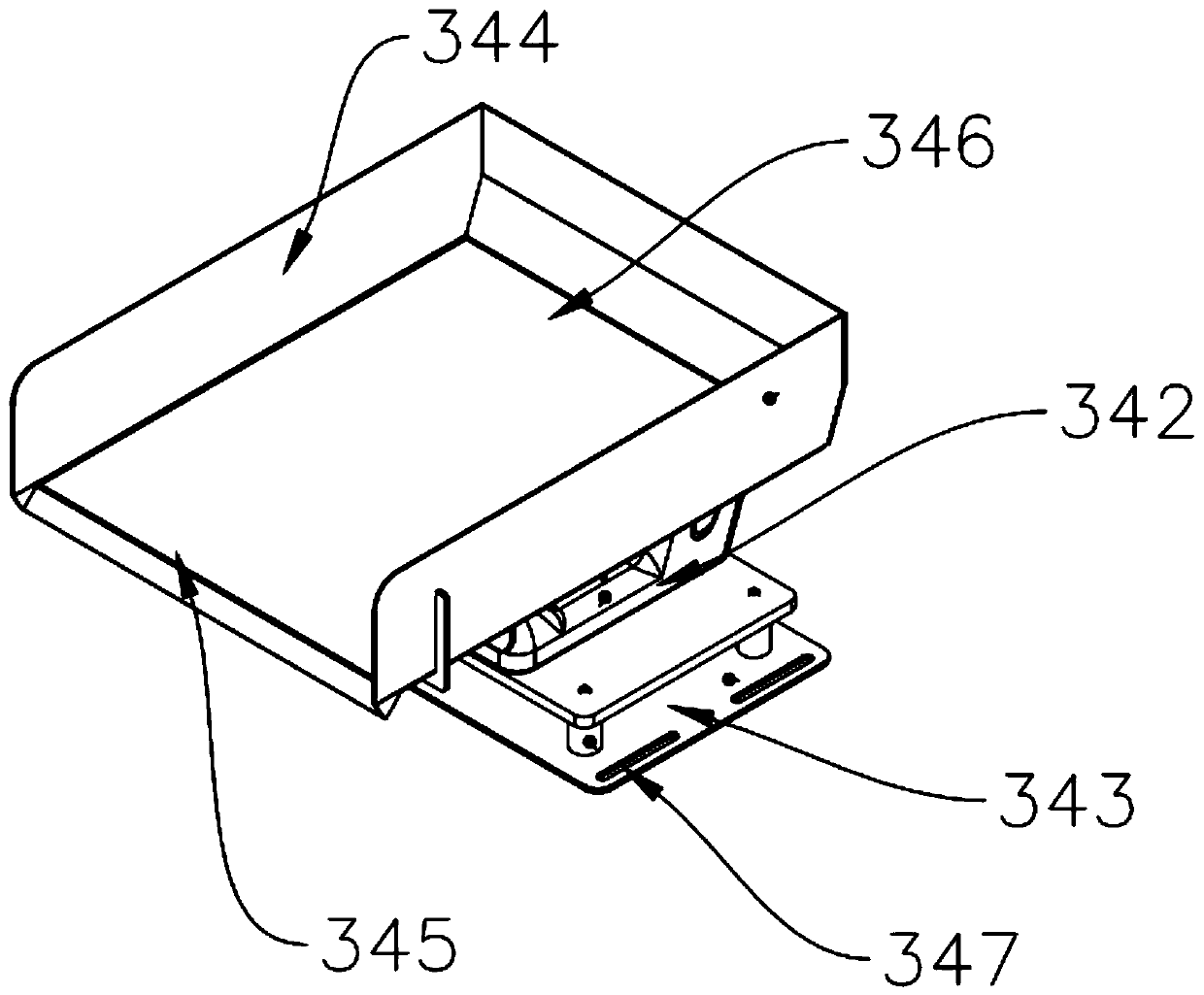

[0031] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

[0032] In the prior art, a layer of vibration device is installed on the color sorter, and the color sorting materials are dispersed through a layer of vibration, and then enter the color sorting chute, and are color sorted in the color sorting box. However, the color sorter is sorting some color sorting materials with poor fluidity, such as tea leaves, plastic sheets, etc. After the existing vibration, these color sorting materials still have some clusters, which cannot be dispersed and are in a stacked state. Entering the color sorting box for color sorting will affect the recognition effect of the color sorter, and even cannot be sorted by color. Based on this problem, the upper and lower layer vibrating devices in the technical solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com