Prediction method of long-term aging performance degradation of high-Nb type GH4169 alloy

A GH4169, performance prediction technology, applied in the direction of prediction, data processing application, calculation, etc., can solve problems such as limiting the accuracy of service life of alloys, the law of tissue degradation, and the complexity of performance evolution, so as to improve efficiency, safety, reliability and accuracy and engineering value effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Performance (hardness) prediction and stability analysis of high-Nb type GH4169 superalloy at high temperature 720°C for long-term aging for 10,000 hours. The composition of the superalloy is C: 0.03; Cr: 18.0; Ni: 53.5; Co: 0.004; Mo: 3.1; Al : 0.5; Ti: 1.1; Nb: 5.5; B: 0.004; P: 0.015; Within 10000h. Design the following long-term aging experiment:

[0047] Long-term aging time length t (unit: h / hour): 30, 100, 200, 500, 1000, 2000, 3000, 4000, 5000, 7000, 10000;

[0048] Long-term aging service temperature: 720°C.

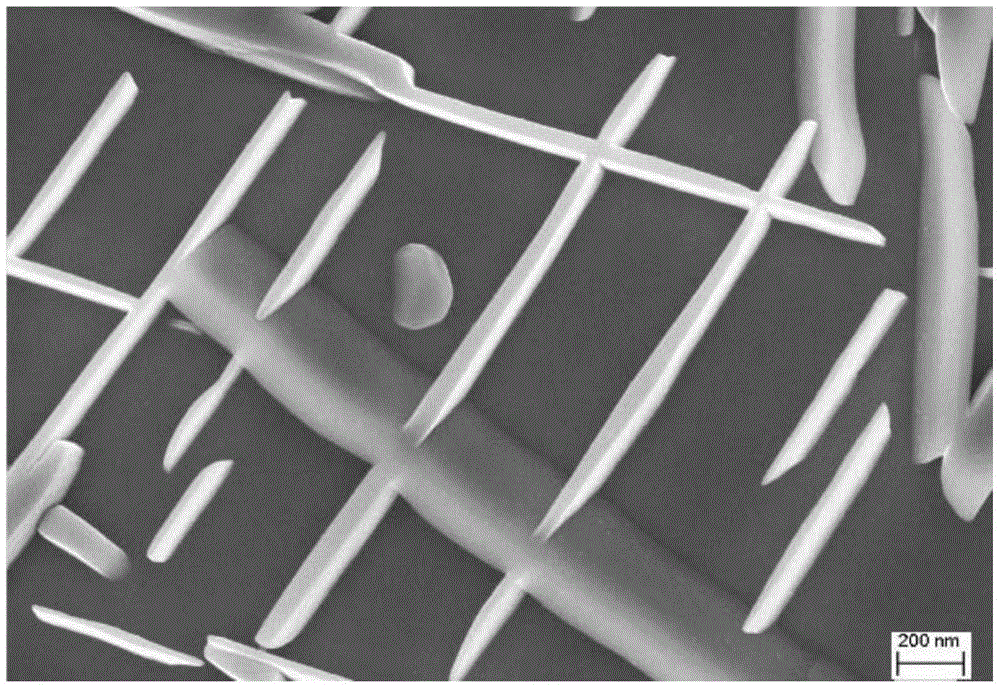

[0049] The experimental results (t 1 ,P 1 , t 2 ,P 2 、......t m ,P m , the actual experimental results are shown in Table 1, figure 2 The microstructure characteristics of the alloy after long-term aging of 10000h are shown: the interior is mainly composed of long needle-shaped δ phase and matrix phase.

[0050] Table 1 Performance and hardness test values of high Nb type GH4169 superalloy during long-term aging at 720℃ for 10000h

[0051] ...

Embodiment 2

[0059] Performance (hardness) prediction and stability analysis of high-Nb type GH4169 superalloy aged at high temperature 700°C for 5000 hours. The composition of the superalloy is C: 0.03; Cr: 18.0; Ni: 53.5; Co: 0.004; Mo: 3.1; Al : 0.5; Ti: 1.1; Nb: 5.5; B: 0.004; P: 0.015; Within 10000h. Design the following long-term aging experiment:

[0060] Long-term aging time length (h / hour): 30, 100, 200, 500, 1000, 2000, 3000, 4000, 5000;

[0061] Long-term aging service temperature: 700°C.

[0062] P=A 0 +A 1 *exp[-(t-A 2 ) / A 3 ]t≤500h;

[0063] P=A 4 +A 5 *exp[-(t-A 6 ) / A 7 ]500h

[0064] Table 3 Performance and hardness test values of high Nb type GH4169 superalloy during long-term aging at 700℃ for 5000h

[0065]

[0066] According to the performance degradation prediction method in the long-term aging process given above, the experimental results (as shown in Table 3) are processed, and the following equation can be obtained:

[0067]

[0068] A...

Embodiment 3

[0073] Performance (hardness) prediction and stability analysis of high-Nb type GH4169 superalloy aged at high temperature 650°C for 4000 hours. The composition of the superalloy is C: 0.03; Cr: 18.0; Ni: 53.5; Co: 0.004; Mo: 3.1; Al : 0.5; Ti: 1.1; Nb: 5.5; B: 0.004; P: 0.015; Within 10000h. Design the following long-term aging experiment:

[0074] Long-term aging time length (h / hour): 30, 100, 200, 500, 1000, 2000, 3000, 4000;

[0075] Long-term aging service temperature: 650°C.

[0076] Table 5 Performance and hardness test values of high Nb type GH4169 superalloy during long-term aging at 650℃ for 5000h

[0077]

[0078] According to the performance degradation prediction method in the long-term aging process given above, the experimental results (as shown in Table 5) are processed, and the following equation can be obtained:

[0079]

[0080] According to the least squares theory, the experimental value and the calculated value are fitted and verified, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com