Novel liquid crystal display screen of black matrix structure and preparation method thereof

A liquid crystal display, black matrix technology, applied in nonlinear optics, instruments, optics, etc., can solve the problem of uneven black material coating black material, product reliability cannot be guaranteed, reduce non-display pixel light transmittance, etc. problems, to achieve the effect of reducing defective products, long service life and reducing light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

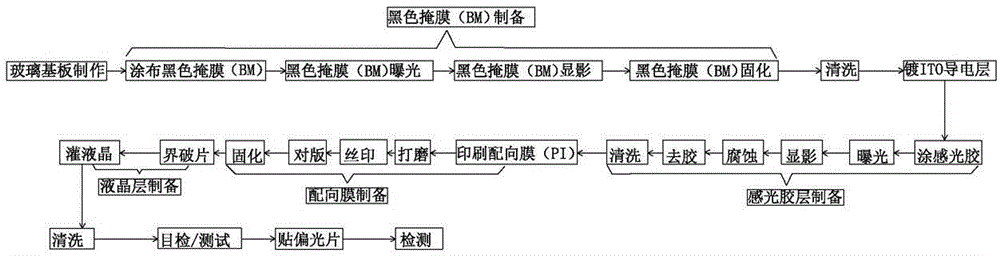

[0045] Attached below Figure 2-4 The present invention is further described.

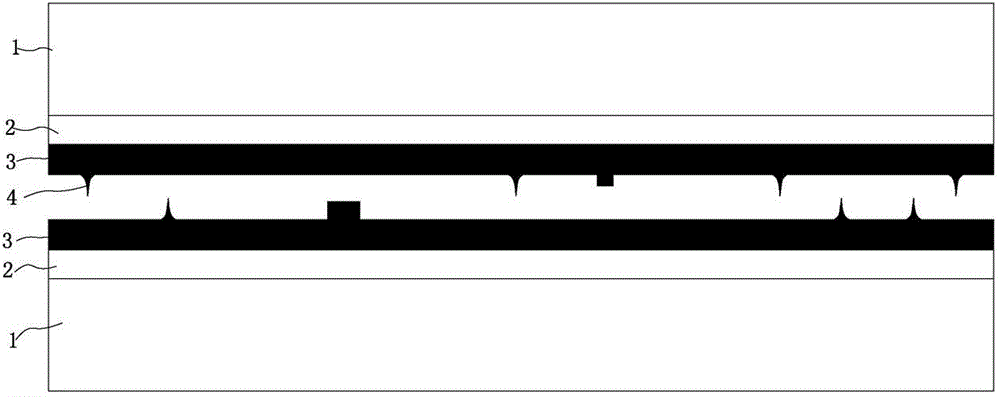

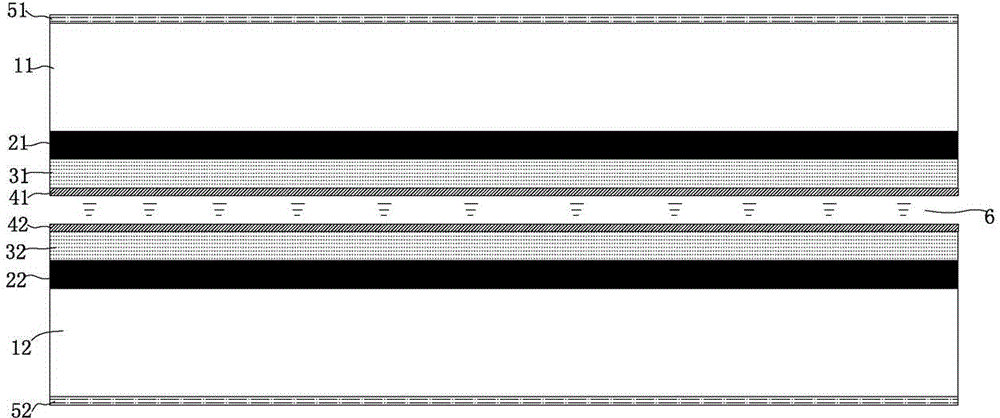

[0046] Such as figure 2 Showing the specific embodiment of the present invention, a novel black matrix structure liquid crystal display, comprising an upper glass substrate 11 and a lower glass substrate 12 arranged opposite to each other, the inner surfaces of the upper glass substrate 11 and the lower glass substrate 12 are A layer of black mask is arranged on the top, which is respectively an upper black mask 21 and a lower black mask 22; An upper ITO conductive layer 31 and a lower ITO conductive layer 32 are respectively provided on the film 22, the two ITO conductive layers are indium tin oxide electrodes for displaying pixel patterns, and the two ITO conductive layers correspond to cover the corresponding upper Black mask 21 and lower black mask 22; a liquid crystal layer 6 is arranged between the two ITO conductive layers, and a matching upper alignment film 41 and a lower alignment film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com