Inlaying source device used for scintillation crystal detector gain automatic control

A technology of automatic gain control and scintillation crystal, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of little performance change, low detection efficiency, and difficult production, and achieve simple production process, high light collection efficiency, and detection The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

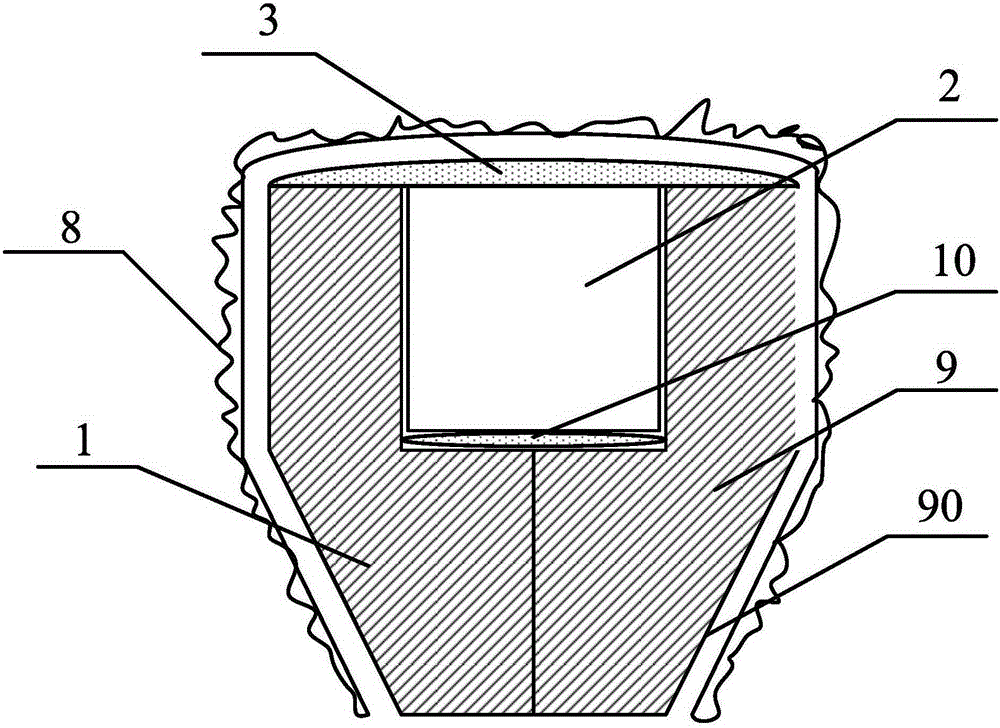

[0023] figure 1 It is a schematic diagram of the mosaic source device used for the automatic control of scintillation crystal detector gain of the present invention. As shown in the figure, the present invention includes: a plastic scintillator cylinder 1 , a plastic scintillator cylinder 2 and an epoxy resin layer 3 .

[0024] Attached to the bottom of the plastic scintillator cylinder is a 241 Am radioactive source 10;. The plastic scintillator cylinder 2 is plugged into the plastic scintillator cylinder 1, and against the 241 Am radiation source 10, thereby forming plastic scintillator 9, plastic scintillator 9 outside has reflective coating 90; 241 The Am radiation source 10 is sealed inside the plastic scintillator 9 .

[0025] 241 The Am radioactive source is specifically passed by the 241 The Am radioactiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com