Static seal fluorubber O-shaped ring service life prediction method

A prediction method, fluororubber technology, applied in the direction of testing the strength of materials by applying stable tension/pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Step (1): Use the compression fixture to obtain the recovery height data of the static seal fluororubber O-ring at different temperatures and different test times:

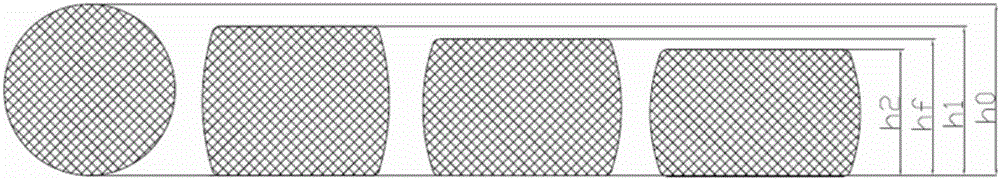

[0045] 1.1 The original axial cross-sectional diameter of a batch of statically sealed fluororubber O-ring products is used as the initial height h 0 =6.50mm, take the actual compression ratio of the installation groove κ=17% as the compression ratio used in the test; the actual service temperature T W It is 160°C (ie 433K);

[0046] 1.2 After using for a period of time, cut off a segment with a length of 2cm from the static seal fluororubber O-ring product as the sample to be tested, and measure the actual axial cross-sectional diameter h of each sample to be tested 1 is 6.38mm, then put the sample to be tested into the compression fixture, and compress it to the height h along the axial direction 2 5.40mm;

[0047] 1.3 Put the compression fixtures containing the samples to be tested into different hot ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com