Measuring tool for measuring the width of inner ring groove on inclined plane

A technology of width measurement and inner ring groove, which is applied in the field of measuring instruments, can solve the problems of not being able to measure the width of grooves with beveled edges, inconvenient operation for workers, time-consuming and laborious, etc., and achieve short measurement time, good economy and easy manufacture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

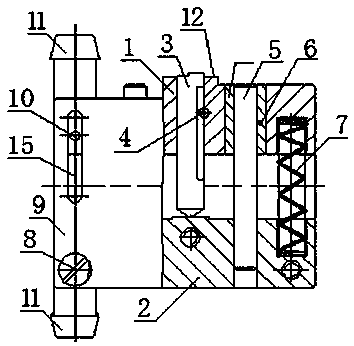

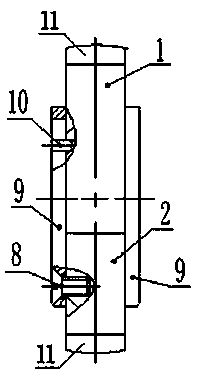

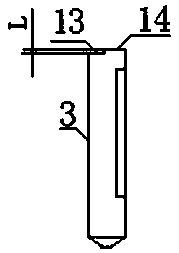

[0018] The measuring tool of the present invention includes an upper gauge block 1, a lower gauge block 2 and a limiting plate 9 connecting the upper gauge block 1 and the lower gauge block 2, and a detection plane B13 and a detection plane C14 are provided on the measuring rod 3. The lower gauge block 2 is provided with a gauge bar 3 and a slide bar 5, and the gauge bar 3 and the slide bar 5 are firmly connected with the lower gauge block 2. The upper gauge block 1 is provided with a measuring plane 12 and a gauge rod through hole and a slide rod through hole corresponding to the gauge rod 3 and the slide rod 5 on the lower gauge block 2 , and a bushing 6 is arranged in the slide rod through hole. The measuring rod 3 and the sliding rod 5 are respectively placed in the measuring rod through hole and the bushing 6, there is a gap of 0.02 mm between the measuring rod 3 and the measuring rod through hole, and there is a gap of 0.01 mm between the sliding rod 5 and the bushing 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com