A multi-safety and energy-saving fire test furnace

A test furnace, energy-saving technology, applied in the direction of furnace, furnace type, lighting and heating equipment, etc., to achieve the effect of ensuring safety and testing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

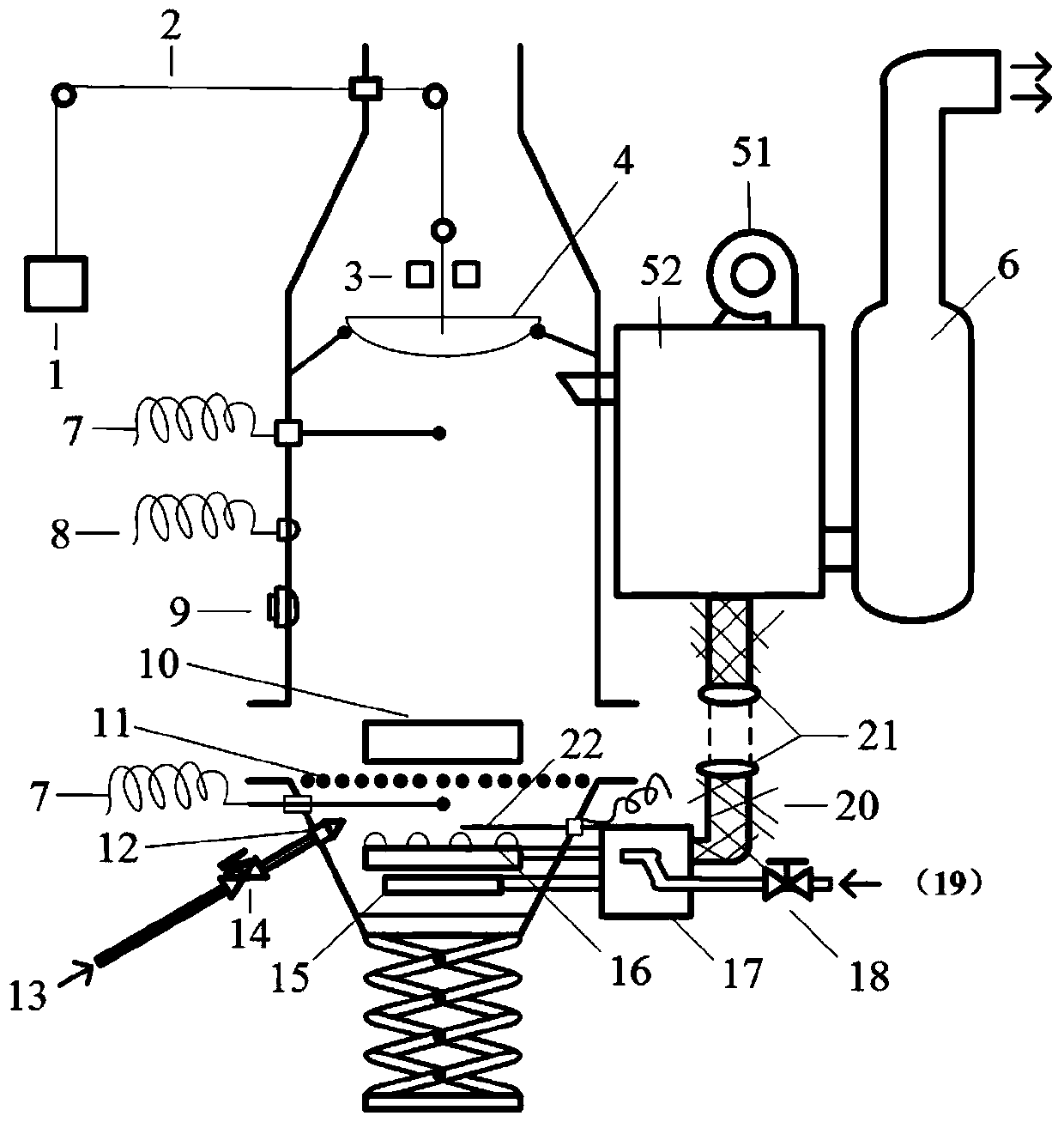

[0042] A multiple safe and energy-saving fire test furnace, its structure is as follows figure 1As shown, it consists of a sealed furnace body, a heat exchanger 52 and an exhaust gas processor 6 connected in sequence. The sealed furnace body is a structure that can be opened and closed, and the outside is covered with thermal insulation materials. The upper furnace body is provided with a safety valve 4, and the top is provided with an air outlet, and the lower furnace body is provided with a container 10 for placing samples, a burner 16 and an air supply pan 15. The heat exchanger 52 is connected with the air distributor 17 through the hot air pipe 21, and the hot air pipe 21 is covered with an insulating layer 20 to control the temperature. The air distributor 17 is connected with the burner 16 and the supplementary air pan 15 arranged in the sealed furnace body, and a blower 51 is provided on the heat exchanger 52 in addition. Air is supplied into the air distributor 17 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com