Valve core structure of a pulverized coal flow regulating valve

A flow regulating valve and spool technology, which is applied in the direction of lift valve, valve device, engine components, etc., can solve the problems of high material and processing costs, easy damage of orifice, and increase maintenance cost of coal chemical enterprises, etc., and achieve easy processing , Easy to install, easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

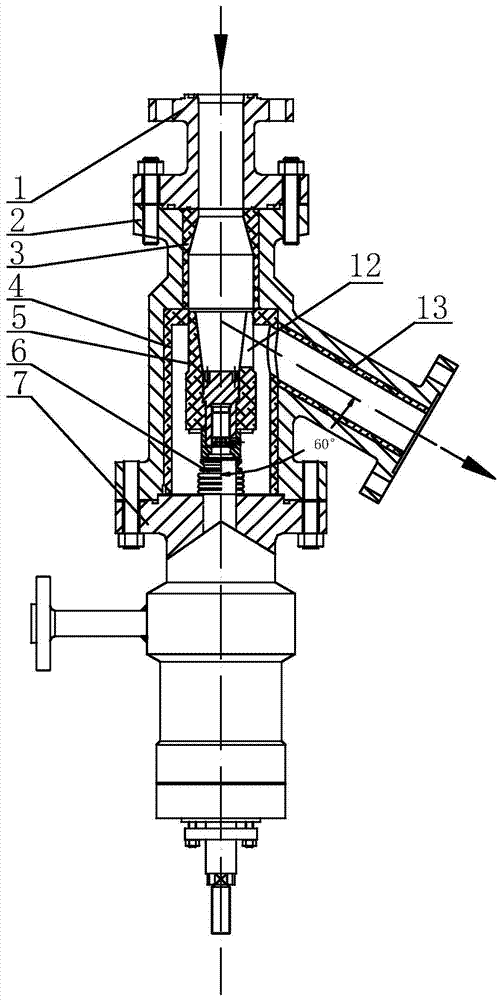

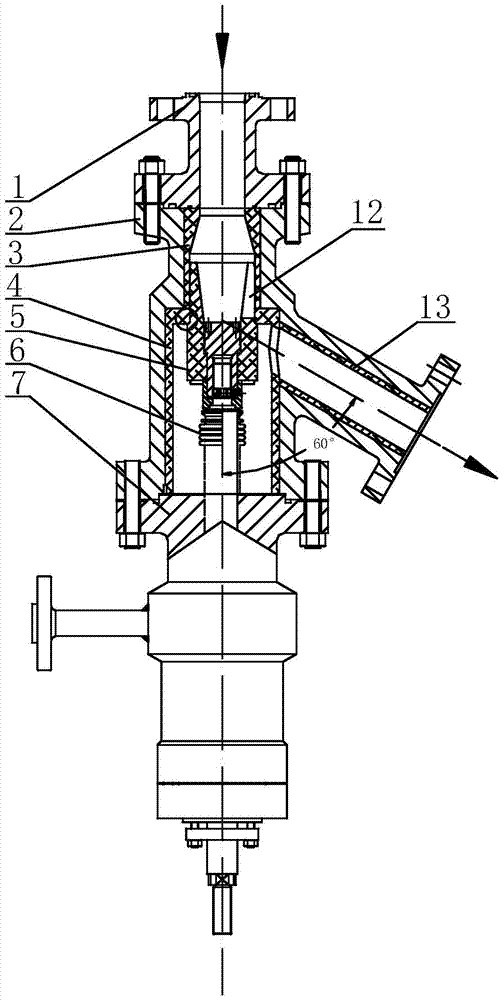

[0022] Below in conjunction with accompanying drawing, structure of the present invention is further described:

[0023] A pulverized coal flow regulating valve includes a valve body 2, on which a fluid inflow port and a fluid outflow port are arranged, and a valve core 5 for regulating the fluid flow is arranged in the valve body 2.

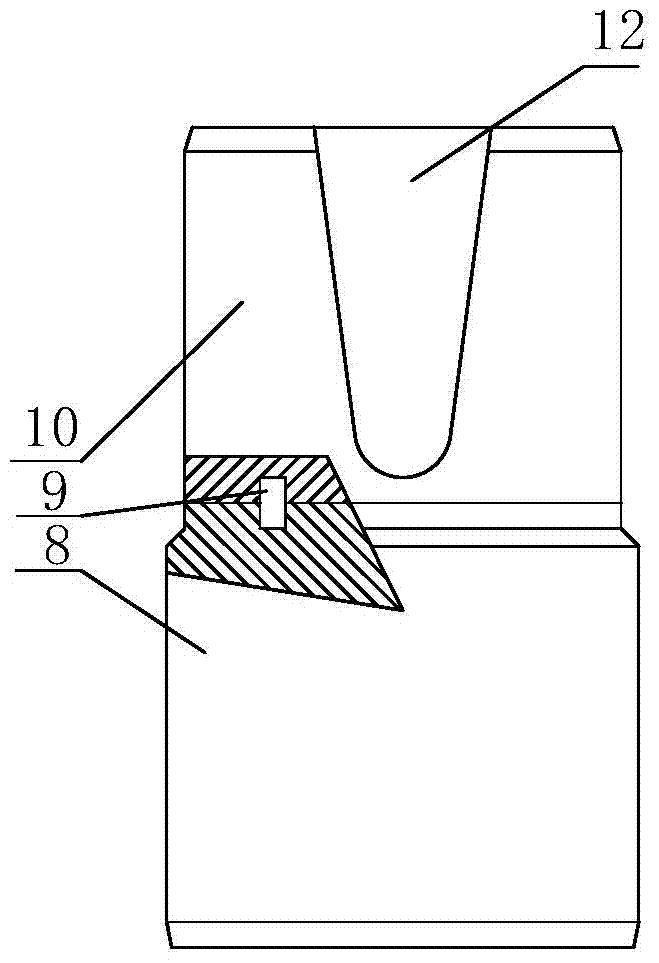

[0024] The inner wall of the valve body 2 is provided with a wear-resistant cermet bushing, and the valve core 5 is made of a wear-resistant cermet material. Since the medium of the valve is high-pressure air-borne coal powder, in order to improve the erosion resistance of the valve, the present invention uses a wear-resistant cermet lining on the inner wall of the valve body 2 and a valve core 4 made of wear-resistant cermet material to isolate the coal powder. Abrasion of pressure-bearing metal valve body 2.

[0025] The valve body bushing is composed of a valve body inlet bushing 3, a valve body middle cavity bushing 4, and a valve body outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com