Bonding structure and construction method of fan foundation steel ring and concrete

A technology of wind turbine foundation and construction method, which is applied in the direction of basic structure engineering, construction, etc., can solve problems such as complex force characteristics, and achieve the effects of ensuring safe operation, good stress transmission, and strong penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

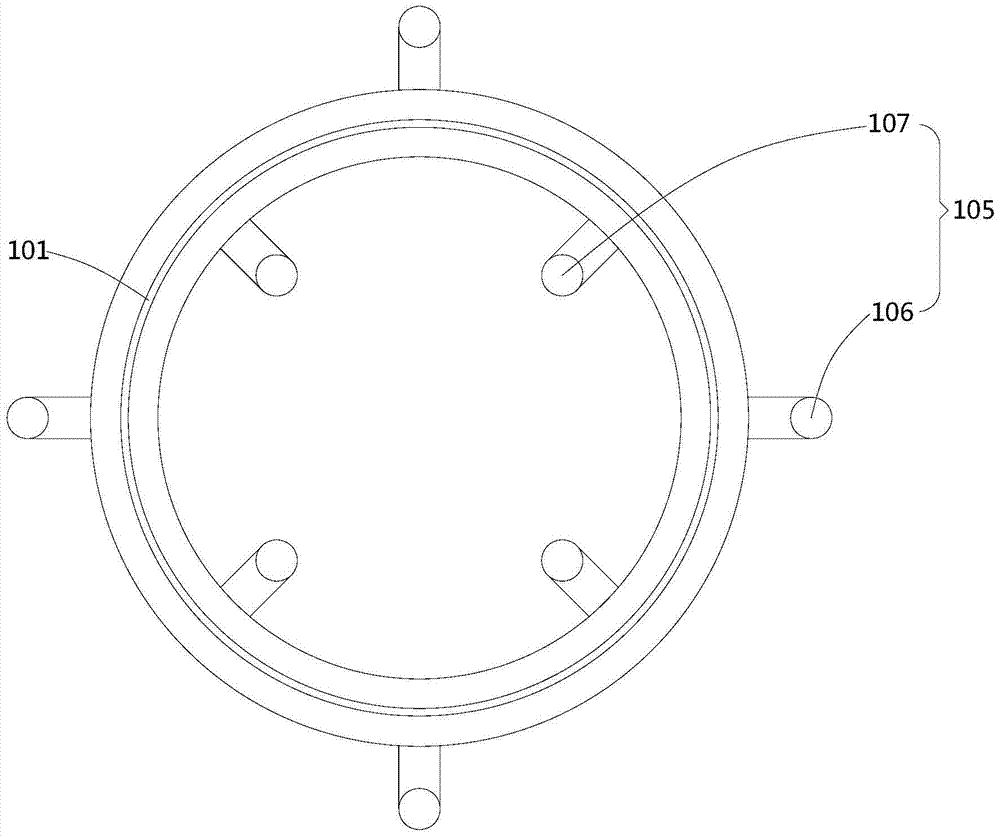

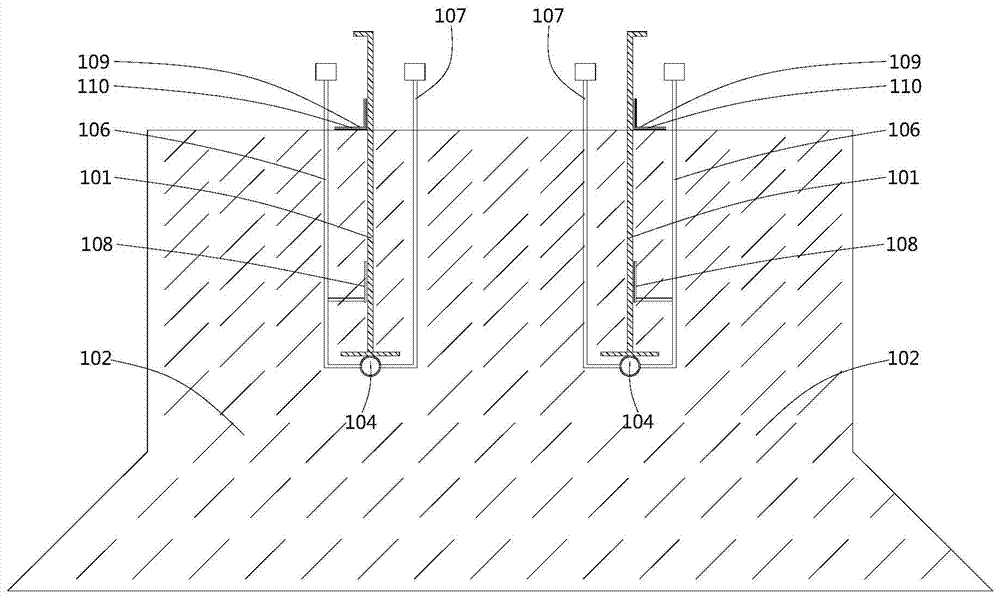

[0039] see Figure 1 ~ Figure 4 , this embodiment provides a bonded structure between the fan base steel ring and concrete, the structure includes a fan base steel ring 101 and a concrete base 102, the lower end of the fan base steel ring 101 is set in the concrete base 102, and the fan base steel ring Modified epoxy resin layers 103 are respectively filled between the inner wall, the outer wall and the end plate of 101 and the concrete foundation 102 . The end plate of the fan base steel ring 101 is an existing structure, and the end plate is an annular flange.

[0040] The bonding structure between the fan base steel ring and concrete provided in this embodiment is filled with modified epoxy resin layers 103 respectively between the inner wall, outer wall and end plate of the fan base steel ring 101 and the concrete foundation 102, and the modified epoxy resin layer 103 is modified. The resin bonds the wind turbine foundation steel ring 101 and the concrete foundation 102 i...

no. 2 example

[0052] see Figure 1 to Figure 5 , this embodiment provides a bonding construction method between a fan foundation steel ring and concrete, the construction method is used to construct the bonding structure between the fan foundation steel ring and concrete as provided in the first embodiment, and the construction method includes:

[0053] Step S1002 of pouring modified epoxy resin: respectively pouring modified epoxy resin between the inner wall, outer wall and end plate of the fan base steel ring 101 and the concrete foundation 102 to obtain a modified epoxy resin layer 103 .

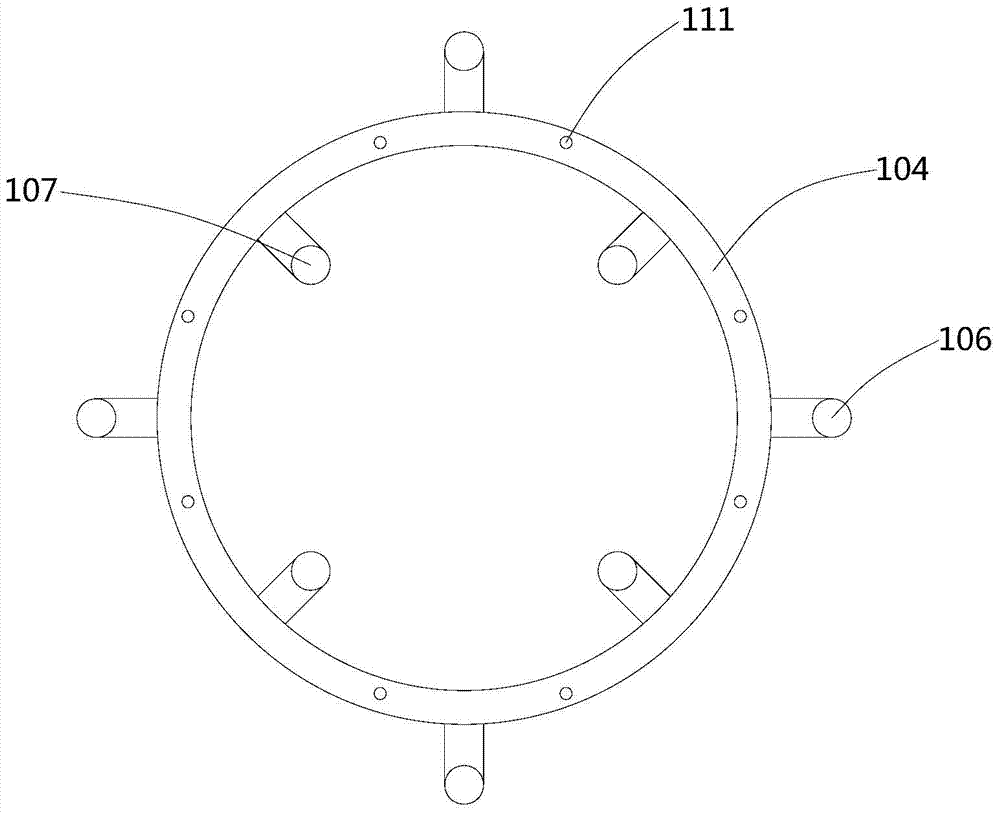

[0054] In order to infuse the modified epoxy resin better, as a preference, the construction method also includes the step S1001 of pre-embedding the grouting pipeline: laying the grouting ring 104 at the lower end of the fan base steel ring 101, and from the grouting ring 104 along the Several grouting pipes 105 are led upwards from the inner and outer walls of the basic steel ring 101, so that the g...

no. 3 example

[0065] see Figure 1 to Figure 5 , this embodiment provides a bonding construction method between the steel ring of the wind turbine foundation and concrete, the construction method is basically the same as the steps in the second embodiment, please refer to the second embodiment for the unexplained steps.

[0066] The bonding construction method between the fan base steel ring and the concrete provided in this embodiment uses the pre-embedded grouting pipe 105, and after the age of the concrete reaches 28 days, it is filled with modified epoxy resin grouting to make the concrete more compact. The construction method includes:

[0067] Embedded grouting pipeline step S1001:

[0068]1. The pre-embedded disposable grouting ring 104 with an inner diameter of 8 mm is used. The grouting ring 104 is a pipe, which is ring-shaped as a whole and has good flexibility. It has the function of a one-way valve 111 and is laid along the bottom of the lower flange of the fan foundation steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com