Photoinduced white light glass and preparing process thereof

A preparation process and glass technology, applied in the field of photowhite light glass and its preparation process, can solve the problem that phosphor powder cannot meet the lighting requirements of high-power white light LED, damage the light efficiency, service life and stability of white light LED, and accelerate the aging of packaging materials and other issues, to achieve good white light luminescence performance, improve chemical stability and thermal stability, and stabilize the light source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

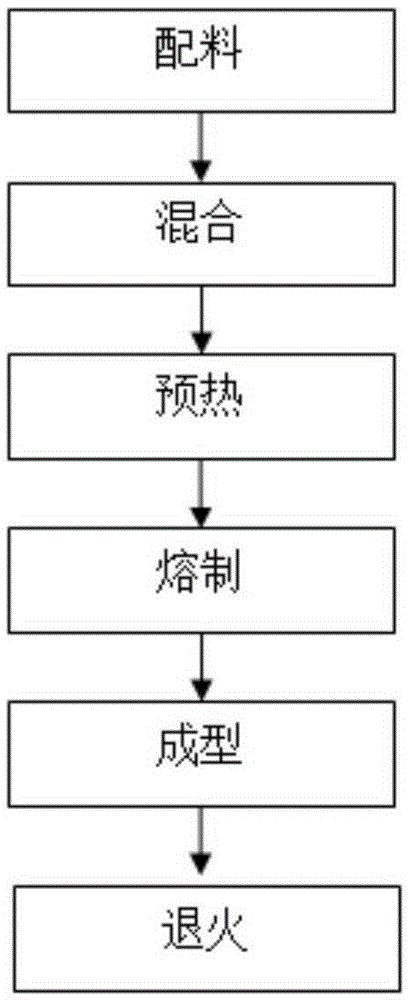

[0039] according to figure 1 Shown flow chart prepares photowhite light glass of the present invention,

[0040] Step 1, ingredients: calculate according to atomic percentage, weigh Sb 2 o 3 10%, Na 2 O6%, Al 2 o 3 12%, ZnO15%, P 2 o 5 55%, BaO1.5%, of which Sm 2 o 3 The dosage is 0.5% of the mass of the matrix glass for batching;

[0041] Step 2, mixing: Stir the ingredients in step 1 fully and mix evenly, because the commonly used P 2 o 5 The raw material contains NH 3 , so every time a raw material is added, it must be fully stirred once to make the raw materials mix evenly;

[0042] Step 3, preheating: place the uniformly mixed batch in step 2 in an annealing furnace, and keep it warm for 4 hours at 250°C;

[0043]Step 4, Melting: Put the batch materials fully insulated in Step 3 into a high-temperature furnace at 220°C, heat up to 1200°C with the furnace, and keep warm for 1 hour in an oxidizing atmosphere to obtain a clarified molten glass;

[0044] Step 5,...

Embodiment 2

[0048] according to figure 1 Shown flow chart prepares photowhite light glass of the present invention,

[0049] Step 1, ingredients: calculate according to atomic percentage, weigh Sb 2 o 3 15%, Na 2 O5%, Al 2 o 3 10%, ZnO20%, P 2 o 5 47%, BaO2%, where Sm 2 o 3 The dosage is 1% of the mass of the matrix glass for batching;

[0050] Step 2, mixing: Stir the ingredients in step 1 fully and mix evenly, because the commonly used P 2 o 5 The raw material contains NH 3 , so every time a raw material is added, it must be fully stirred once to make the raw materials mix evenly;

[0051] Step 3, preheating: place the uniformly mixed batch in step 2 in an annealing furnace, and keep it warm for 4 hours at 220°C;

[0052] Step 4, Melting: Put the batch material fully insulated in Step 3 into a high-temperature furnace at 220°C, heat it to 1100°C with the furnace, and keep it in an oxidizing atmosphere for 1 hour to obtain a clarified molten glass;

[0053] Step 5, molding:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com