Treatment method and system of waste water produced by acid preparation from pyrite

A treatment method and pyrite technology are applied in the treatment method and system field of pyrite acid-making wastewater, which can solve the problems of decline, unsatisfactory arsenic removal effect, complex composition and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

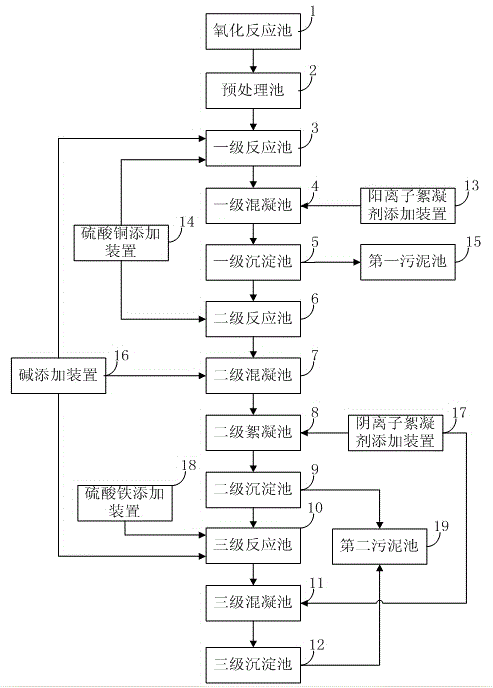

[0031] see figure 1 , Embodiment 1 provides a kind of treatment system of pyrite acid production waste water, and this system comprises sludge pool, copper sulfate adding device 14, ferric sulfate adding device 18, alkali adding device 16, cationic flocculant adding device 13, anion Flocculant adding device 17 and oxidation reaction tank 1, pretreatment tank 2, primary reaction tank 3, primary coagulation tank 4, primary sedimentation tank 5, secondary reaction tank 6, and secondary coagulation tank 7 connected in sequence , the secondary flocculation tank 8, the secondary sedimentation tank 9, the tertiary reaction tank 10, the tertiary coagulation tank 11 and the tertiary sedimentation tank 12, etc. Wherein, the copper sulfate adding device 14 is connected with the primary reaction pool 3 and the secondary reaction pool 6, and the iron sulfate adding device 18 is connected with the tertiary reaction pool 10. The sludge tank is connected with the primary sedimentation tank 5...

Embodiment 2

[0038] see figure 1 , Example 2 provides a treatment method for pyrite acid-making wastewater. The main process of the method is: inject the wastewater into the oxidation reaction tank 1 to react with the oxidant (sodium hypochlorite solution), oxidize for a certain period of time, and transport it with the oxidizing solution The pump is pumped into the pretreatment tank 2 to react with milk of lime to control the pH value; after pretreatment, the waste water is sent to the primary reaction tank 3, and liquid caustic soda and copper sulfate are added to the primary reaction tank 3 to control a certain pH value With the addition of copper sulfate. When the mixed solution overflows into the primary coagulation tank 4, a certain amount of cationic flocculant is added. After the liquid in the primary coagulation tank 4 overflows to the primary sedimentation tank 5 for sedimentation and separation, the supernatant of the primary sedimentation tank 5 overflows into the secondary re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com