A kind of hoisting and conveying equipment for glass production line

A technology for production lines and conveying equipment, applied in cranes and other directions, can solve the problems of heavy workload of staff, injury to staff, time-consuming and laborious, etc., and achieve the effects of good weighing stability, reduced friction damage and strong corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

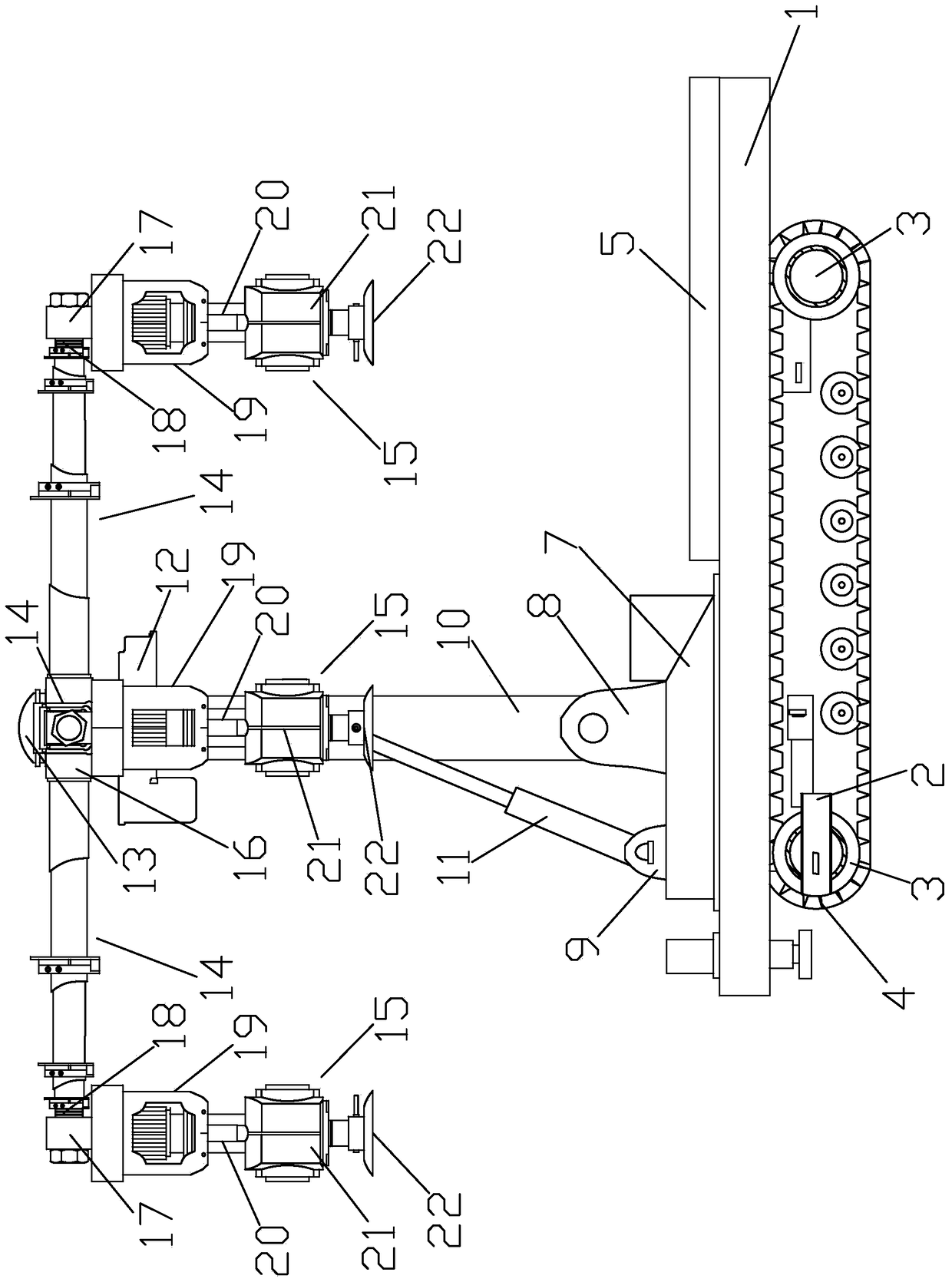

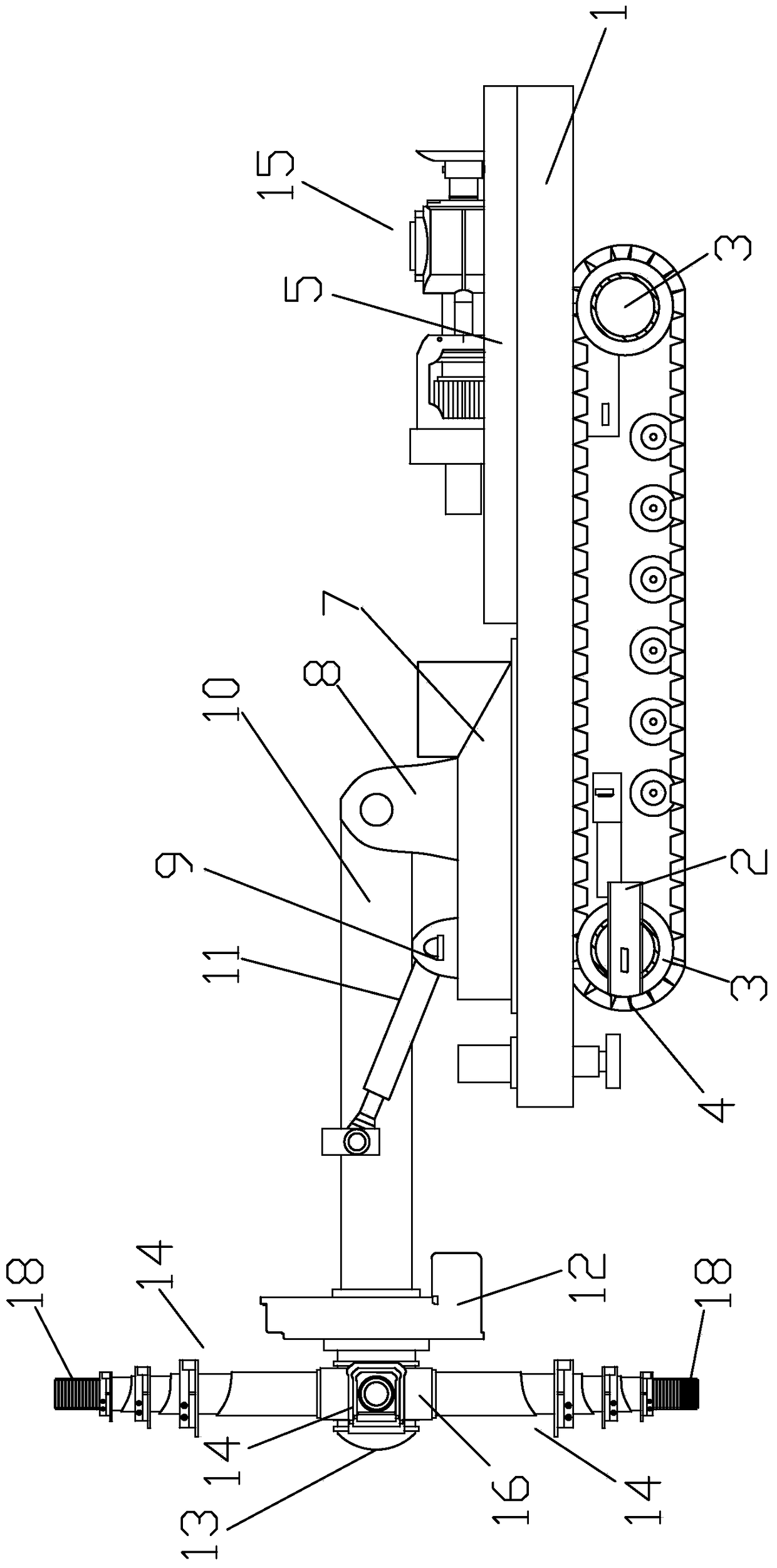

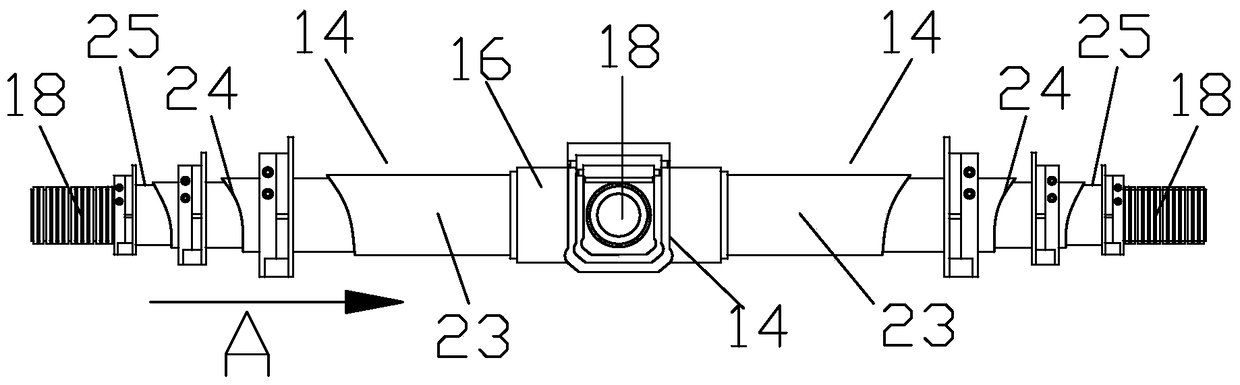

[0030] Such as Figure 1 to Figure 7 As shown, a hoisting and conveying equipment used in a glass production line includes a frame 1, a conveying mechanism and a hoisting mechanism. The upper surface of the frame 1 is laid with a sponge pad (not shown in the figure), the sponge pad completely covers the upper surface of the entire frame 1, the sponge pad has a buffering effect, slows down the impact force between the glass workpiece and the frame 1, and avoids The glass workpiece is broken. The outer side of the upper surface of the frame 1 is equipped with a guardrail 5, the guardrail 5 wraps the sponge pad inside to form a groove, and glass workpieces can be installed in the groove, and the guardrail 5 surrounds the glass to prevent it from sliding down from the frame 1 And broken, to prevent glass waste.

[0031]A base 7 is installed on the upper end of the frame 1, and the base 7 is welded on the frame 1. The hoisting mechanism includes a boom 10, a turntable 12, a tele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com