Suspension structure used for glass transferring

A suspension structure and glass technology, applied in the field of structure and steel structure, can solve the problems of product damage, large labor cost, and many glass products, and achieve the effects of avoiding damage, convenient operation and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

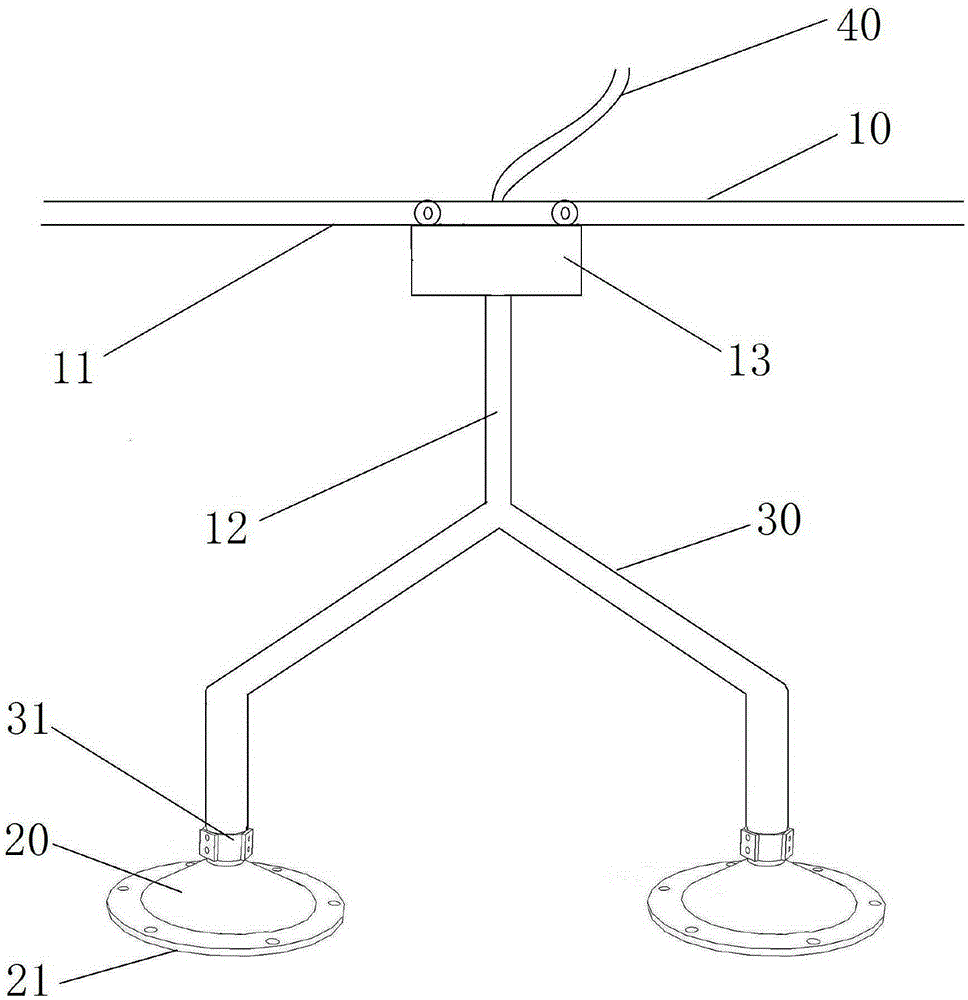

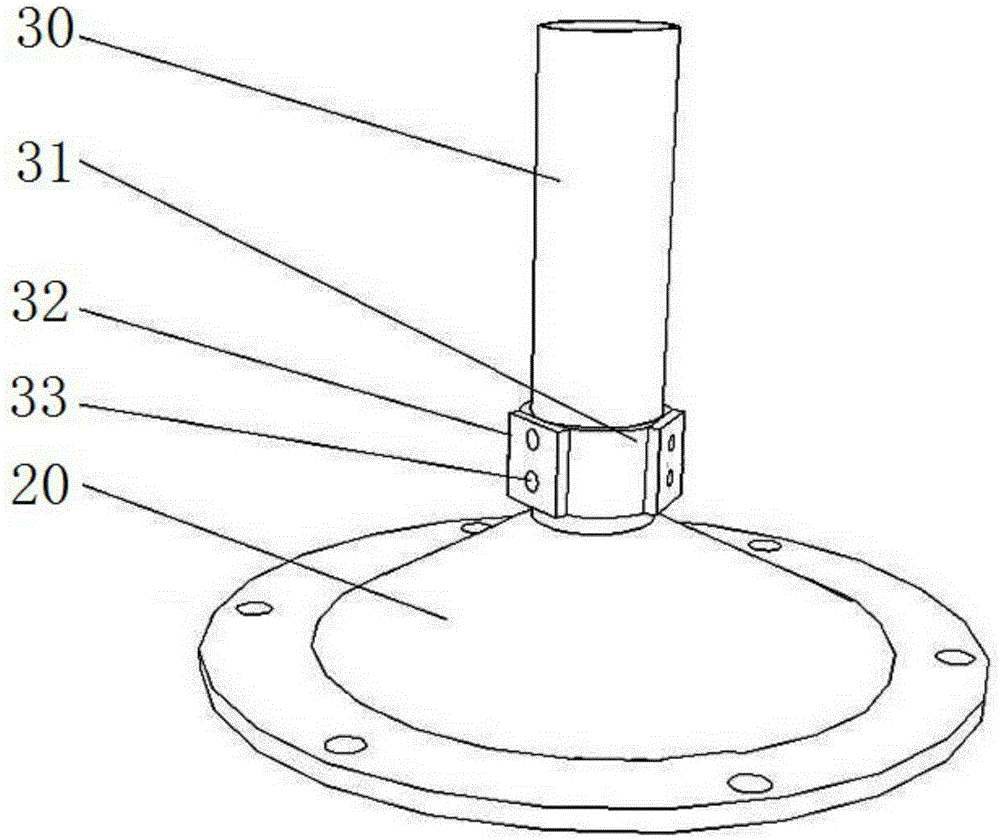

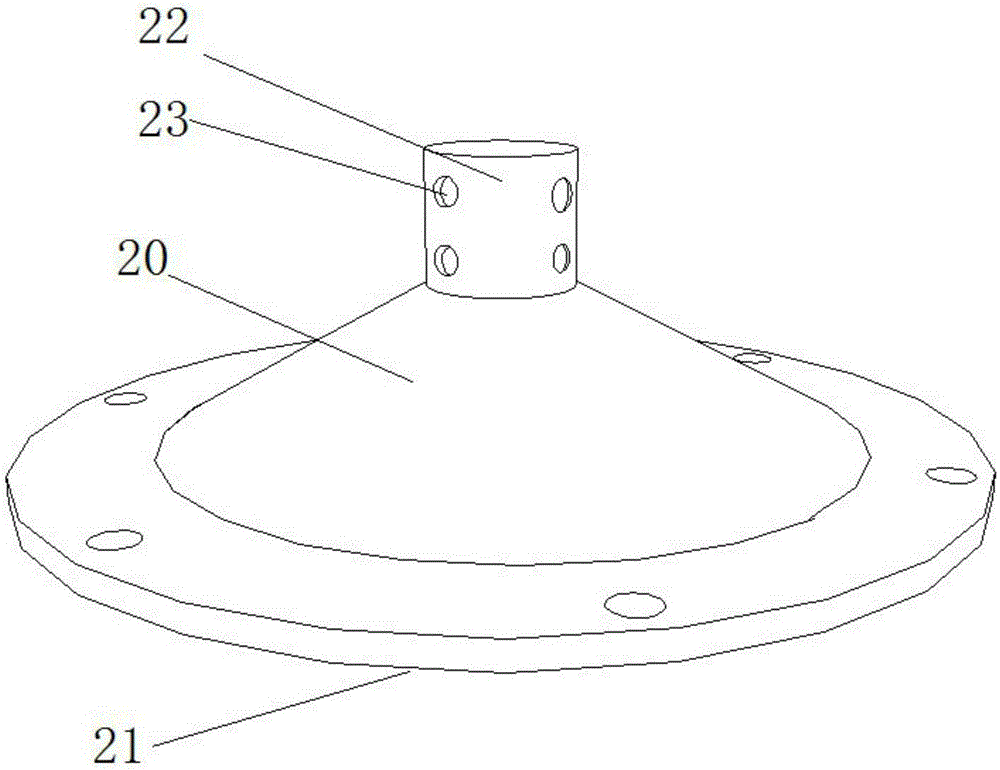

[0014] Such as Figure 1 to Figure 3 As shown, a suspension structure for glass transfer includes a transfer frame body 10 and a suction cup 20, the transfer frame body 10 includes a suspension guide rail 11 and a telescopic hollow tube 12, and one end of the telescopic hollow tube 12 is connected through a suction tube 40 The air extraction device is suspended on the suspension guide rail 11 by the guide trolley 13, and the other end is divided into two symmetrically arranged steel pipes 30; On the connection column 22, the outer wall of the sleeve 31 is provided with a fixed plate 32, and the fixed plate 32 is provided with a bolt through hole 33. The connection column 22 is provided with a depression 23 that is consistent with the position of the bolt through hole 33, and the bolt passes through the bolt. Behind the through hole 33 , the front end goes de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com