Dolly structure

A trolley and structure technology, applied in the direction of trolleys, motor vehicles, trolley accessories, etc., can solve the problems of change, braking, slipping and braking force, etc., to reduce the force and realize the effect of operating force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

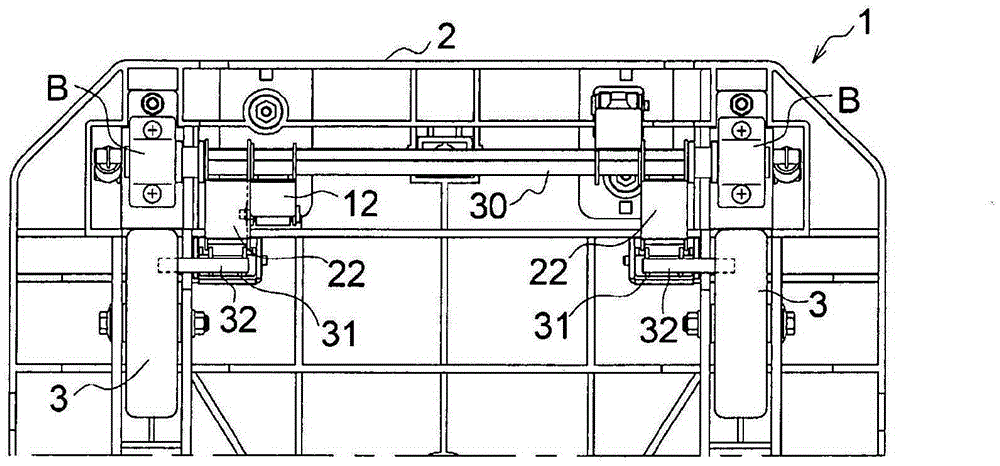

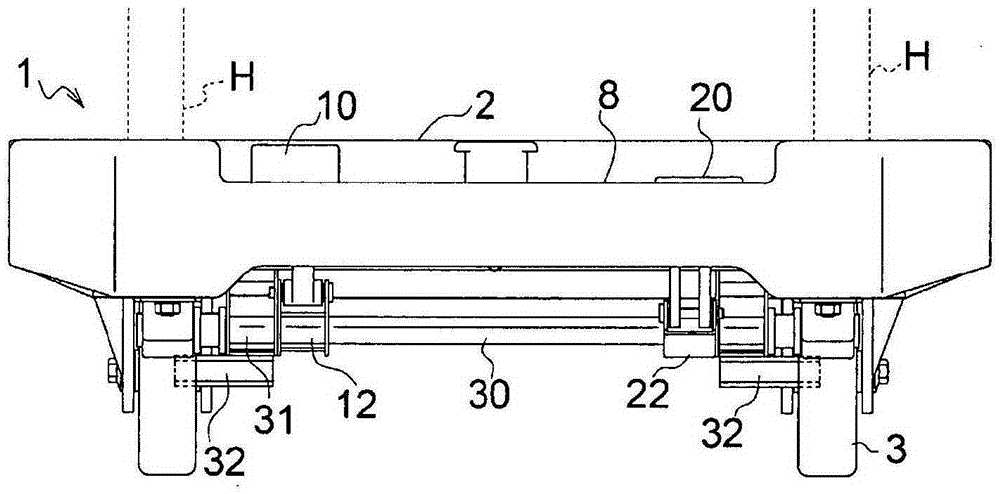

[0042] [Trolley]

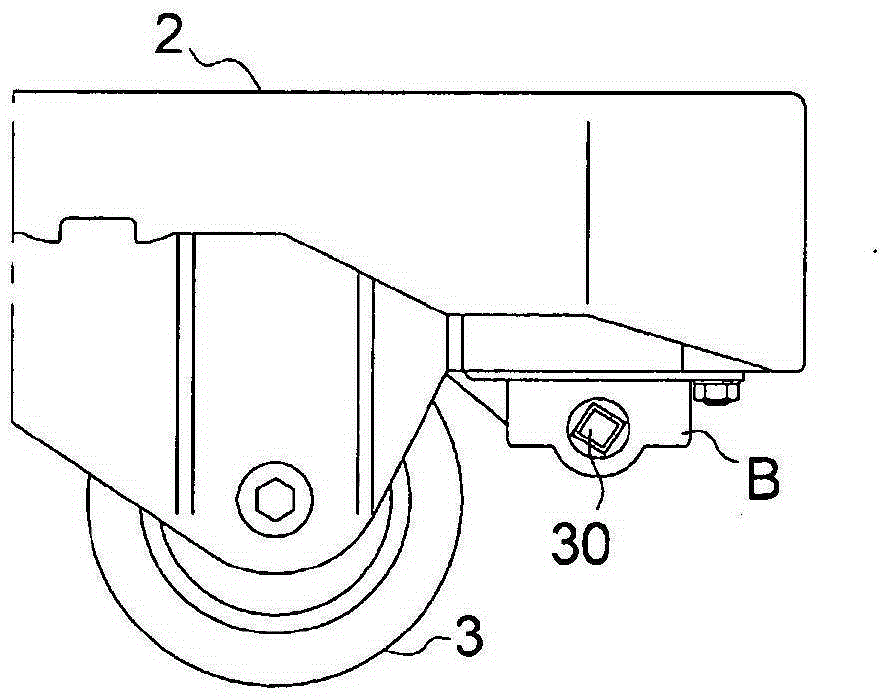

[0043] Such as figure 1 with figure 2 As shown, the trolley 1 is composed of a chassis 2, a handle (not shown), a pair of left and right wheels 3, and a braking mechanism. The front and rear ends of the chassis 2 are chamfered, and its upper surface becomes a loading surface. The handle is erected near one side of the chassis 2, and the left and right pair of wheels 3 are arranged at the front and rear of the bottom of the chassis 2, and the brake mechanism brakes the wheels 3 on the rear wheel side.

[0044] The wheel 3 has a small-diameter concave portion concentric with the outer circumference, and a gear-shaped internal tooth portion 4 formed of continuous unevenness is formed on the inner peripheral surface of the concave portion.

[0045] Regarding the brake operation, a push-down type brake release pedal 10 and a brake pedal 20 are arranged side by side in the concave portion 8 provided in the space between a pair of legs (H) that are A pair of le...

Embodiment 2

[0083] Figure 9 ~ Figure 11 The shown trolley 1 shows different embodiments as follows: a structure in which a detachable back panel 50 is provided on the handle H, and a structure that is foldable at three positions of the frontmost part and the left and right sides of the chassis 2 via pins 41 Collapsible scatter arrest sheet 40 .

[0084] That is, the scattering prevention sheet 40 is configured to be folded so as to be flush with the upper surface of the chassis 2 when folded (refer to Figure 12 (b), Figure 13 (b) dotted line), and when unfolded, it is unfolded in a manner to stand approximately vertically with respect to the upper surface of the chassis 2 (refer to Figure 12 (a), Figure 13 (a) ~ (b)).

[0085] That is, if Figure 13 As shown in (c), the pin 41 is hooked to the side of the top plate so as not to fall out, and the drop preventing sheet 40 is accommodated in the recessed storage portion 42 so that the outer surface of the folded sheet is flush with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com