Novel magnetic conductive rubber and magnetic conductive tyre charging system used for charging electric automobile in operation

A technology of electric vehicles and rubber, applied in electric vehicles, electromagnetic wave systems, special tires, etc., can solve the problems of wasting charging electric energy, energy waste, and low charging efficiency, and achieve simple and convenient paving construction, extended mileage, and high charging power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and practical examples.

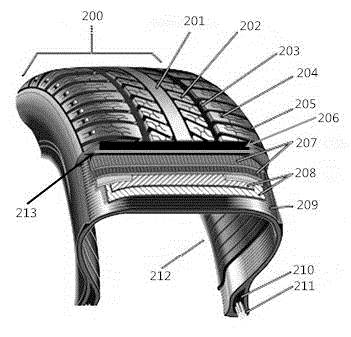

[0029] figure 1 It shows a three-dimensional cross-sectional schematic diagram of the arrangement of the magnetically conductive rubber column (206) and the charging receiving coil (213) in the rechargeable magnetically conductive tire. Taking the most commonly used radial tire as an example, the magnetically conductive rubber column (206) and the charging receiving coil ( 213) in other types of tires in a similar position to radial tires. The magnetically permeable rubber column (206) is a magnetically permeable rubber block similar to a short column shape formed by injecting magnetically permeable rubber into the charging receiving coil (213), the magnetically permeable rubber column (206) and the charging receiving coil (213) Located inside the crown area (200) of the tire, the bottom is connected to the nylon belt layer (207), and there is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com