Connector and LED lamp bar applying connector

A technology of LED strips and connectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

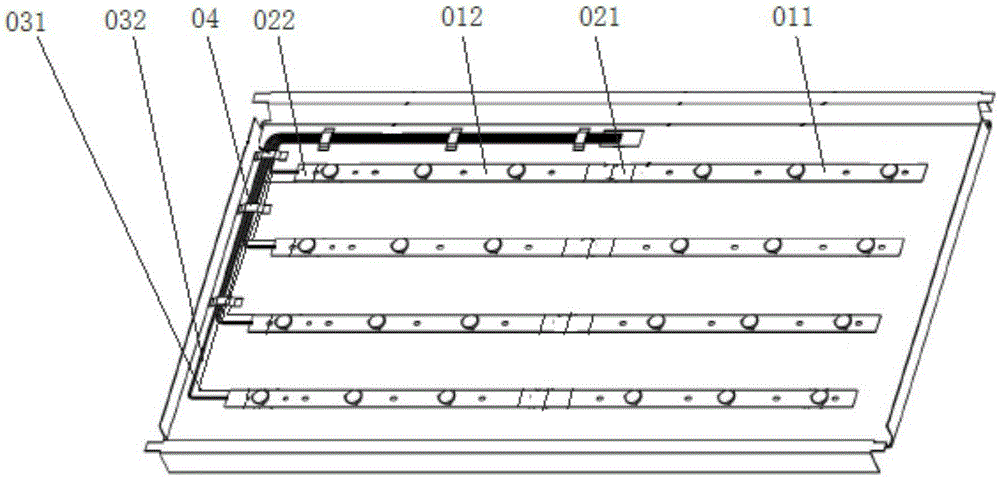

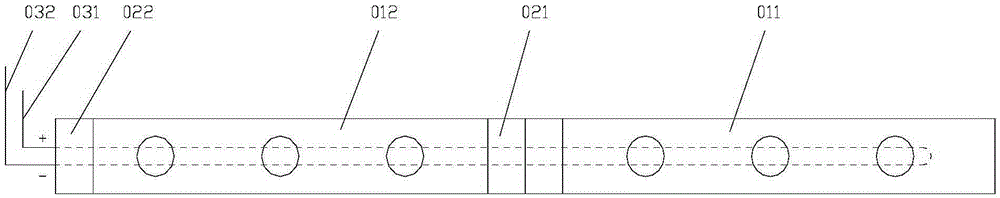

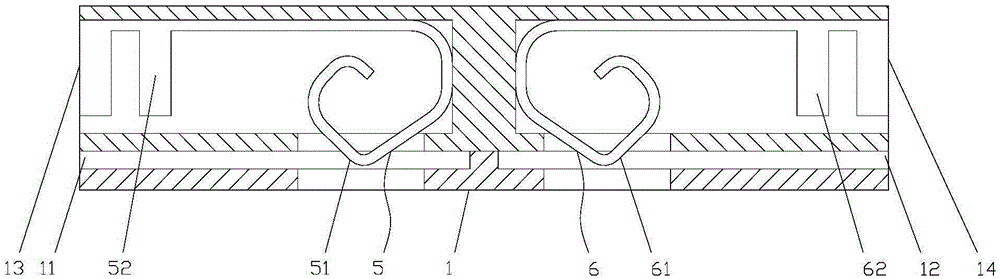

[0027] like Figure 3-4 As shown in one, the connector of the present invention includes a housing 1, and the housing 1 is provided with two light bar interfaces 11, 12 and two wire interfaces 13, 14, and the two light bar interfaces 11, 12 are used for It is connected with two LED light bars 2, the two wire interfaces 13, 14 are used to connect with two wires 3, and the housing 1 is provided with a male terminal 4 and two female terminals 5, 6, the male terminal 4 The two ends are respectively provided with a first male contact 41 and a second male contact 42, and one end of the two female terminals 5, 6 is respectively provided with a first female contact 51 and a second female contact 61, the The first male contact 41 and the first female contact 51, the second male contact 42 and the second female contact 61 are respectively arranged in the two light bar interfaces 11, 12, and the two female terminals 5, 6 The other end is respectively provided with two wrapping pins 52, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com