Battery

A battery and electrolyte technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of limiting the battery and the deterioration of the electrochemical performance of the battery, etc., to improve the cycle performance, improve the floating charge problem and self-discharge problem, improve the battery Effects of chemical properties and safety properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0086] In a preferred embodiment, the separator is a separator that separates the electrolyte into positive electrolyte and negative electrolyte. That is, the first metal ion is confined in the positive electrolyte, and the second metal ion is confined in the negative electrolyte, so that the diaphragm can prevent the mutual contamination of the positive and negative electrolytes, and the electrolyte that is more suitable for the positive or negative can be selected, but it does not affect Ionic charge transfer. For example, using an anion exchange membrane or a hydrogen ion exchange membrane as a diaphragm, the first metal ion in the positive electrolyte cannot pass through the diaphragm, so it cannot enter the negative electrolyte and can only be limited to the positive electrolyte; the second metal ion in the negative electrolyte Metal ions cannot pass through the diaphragm, so they cannot enter the positive electrolyte, and can only be confined in the negative electrolyte....

Embodiment 1

[0090] Lithium manganate LMO, graphite conductive agent SFG-6, and binder PVDF were mixed in water at a mass ratio of 86:7:7 to form a uniform positive electrode slurry. The positive electrode slurry is coated on the positive electrode current collector to form an active material layer, which is then pressed into tablets.

[0091] Zinc foil was used as the negative electrode, and AFG film was used as the separator.

[0092] Weigh a certain mass of zinc sulfate and lithium sulfate, add them to dissolve in water, and configure an electrolyte solution with a concentration of zinc sulfate of 2 mol / L and a concentration of lithium sulfate of 1 mol / L.

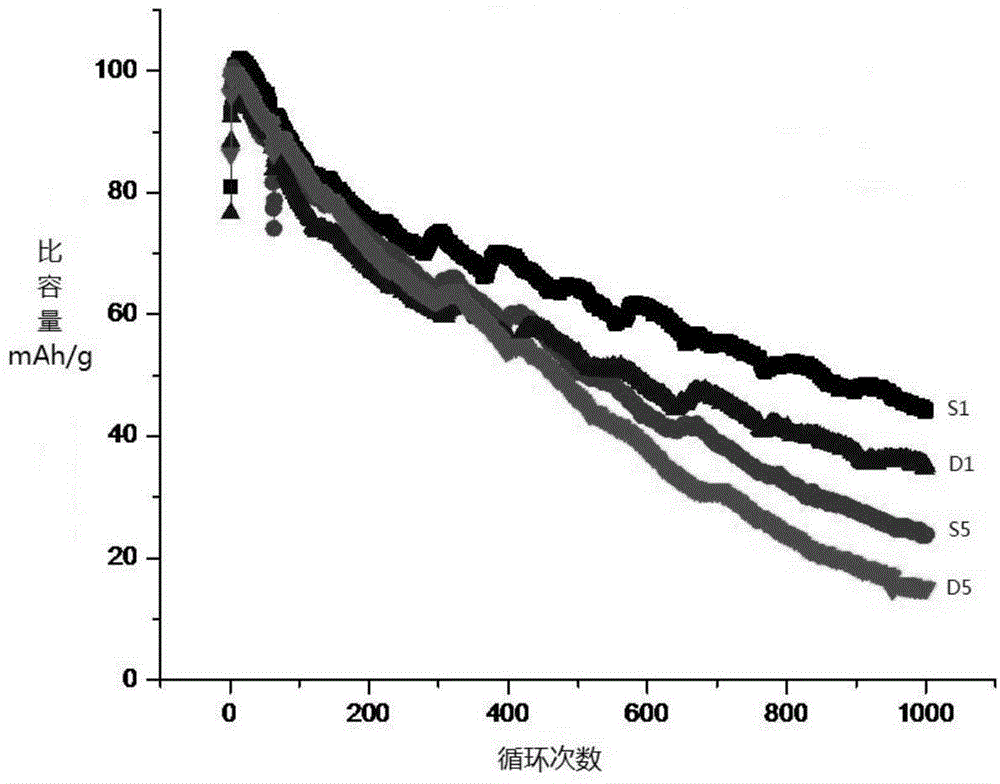

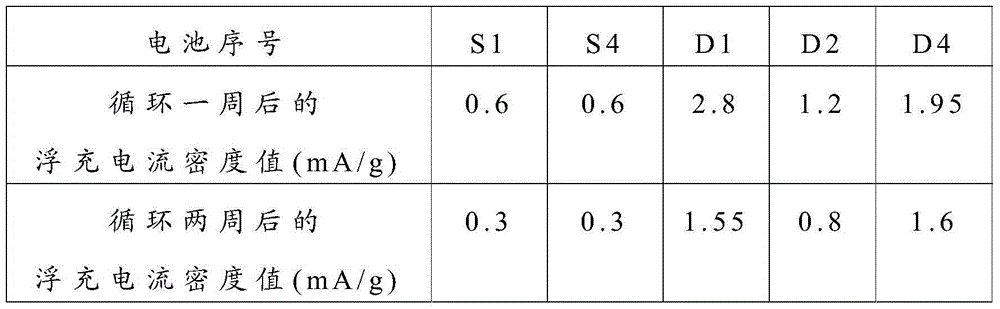

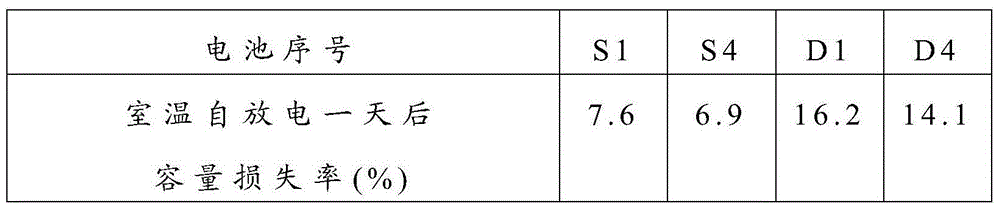

[0093] Assemble the positive electrode, negative electrode and diaphragm into a battery cell, put it into the case, then inject electrolyte, seal it, and assemble it into a button battery with a capacity of 0.7mAh to 1.2mAh, which is designated as S1.

Embodiment 2

[0095] The difference from Example 1 is: Weigh a certain amount of zinc methanesulfonate and lithium methanesulfonate, add them to dissolve in water, and configure the concentration of zinc methanesulfonate to be 2mol / L, and the concentration of lithium methanesulfonate to be 2mol / L. It is 3mol / L electrolyte. Assemble into a button battery with a capacity of 0.7mAh to 1.2mAh, denoted as S2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com